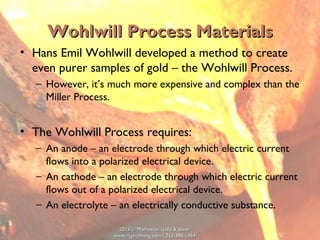

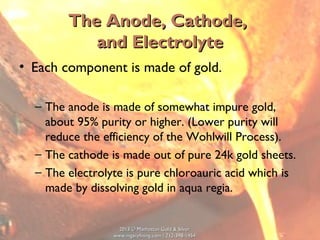

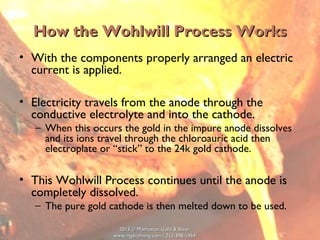

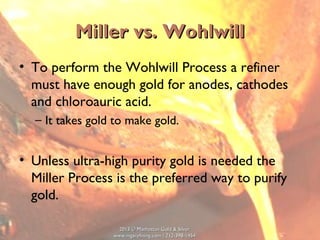

The document outlines two primary methods for refining pure gold: the Miller process and the Wohlwill process. The Miller process is cost-effective and uses chlorine gas to remove impurities, resulting in gold that is approximately 99.95% pure, while the Wohlwill process is more complex and produces even purer gold through electroplating but requires more initial gold investment. Manhattan Gold & Silver, a precious metals refiner, offers services for recycling precious metals and provides resources such as charts and calculators for their customers.