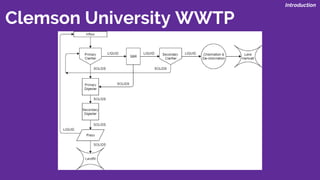

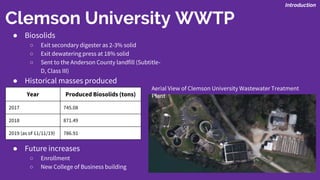

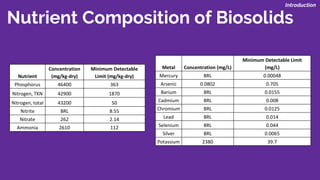

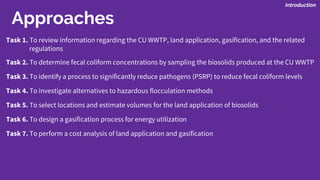

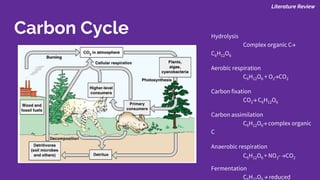

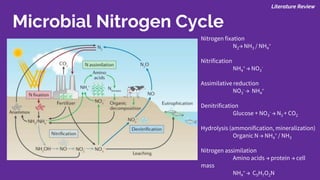

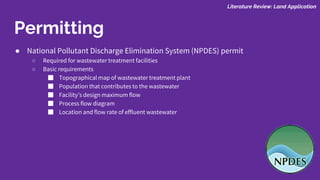

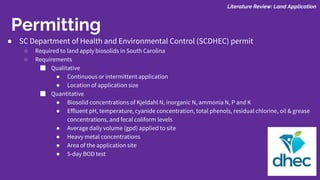

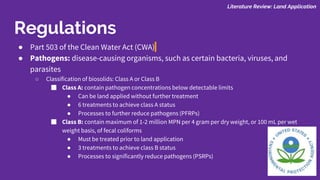

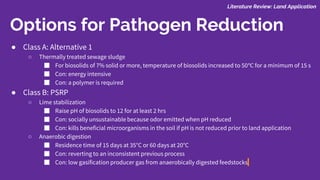

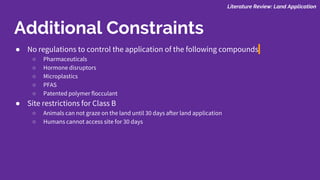

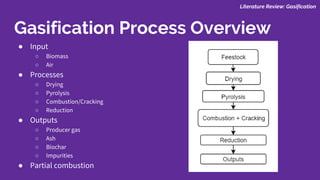

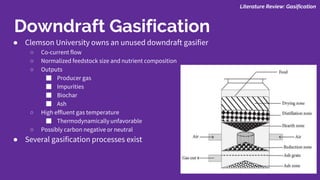

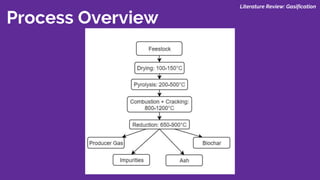

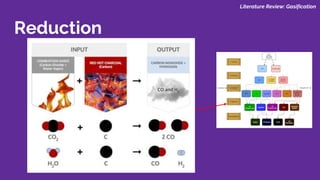

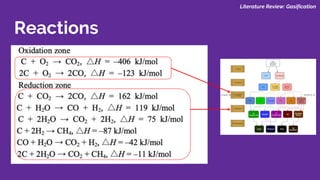

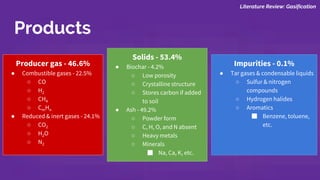

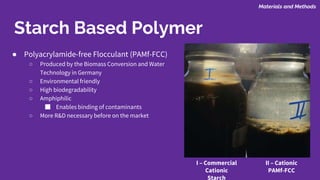

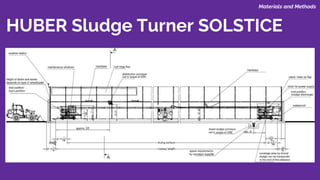

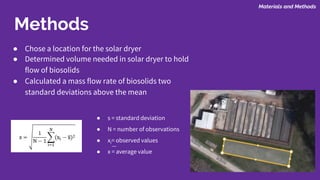

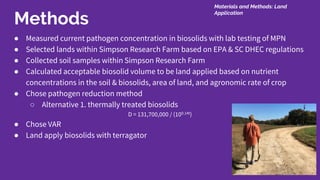

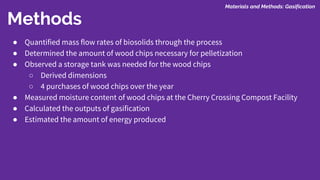

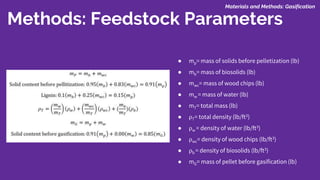

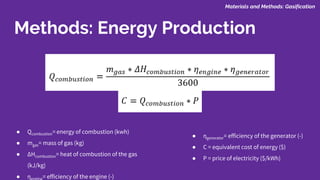

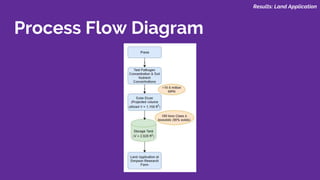

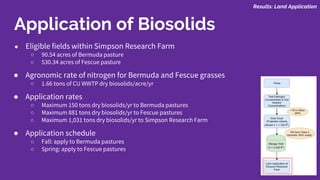

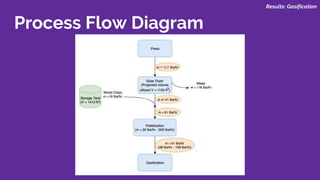

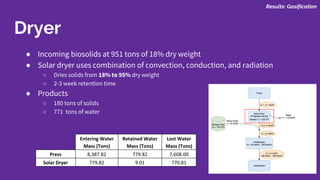

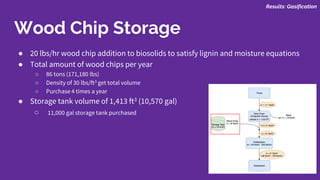

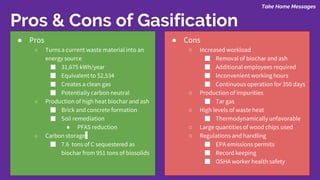

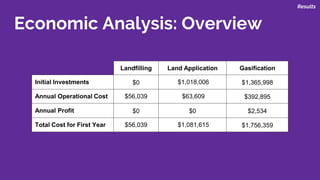

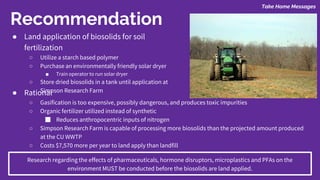

This document outlines a student capstone project to utilize biosolids from Clemson University's wastewater treatment plant. It provides background on biosolids and their potential uses for land application and gasification. The objectives are to design a viable pathway for biosolids use and select the optimal approach. Literature on the relevant regulations, processes, and constraints for land application and gasification is reviewed to inform the project tasks of evaluating and selecting the best utilization method.