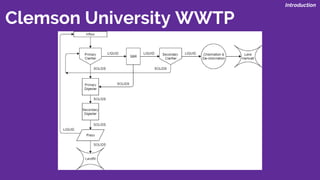

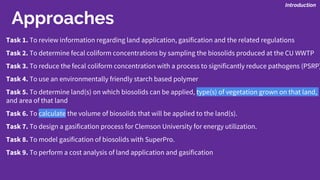

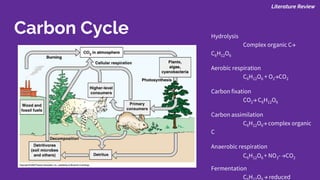

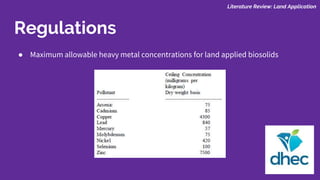

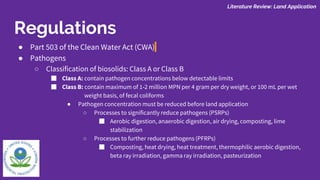

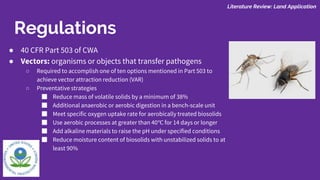

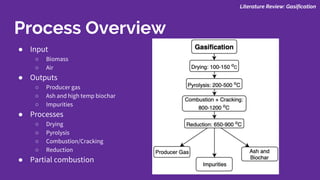

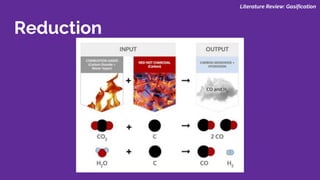

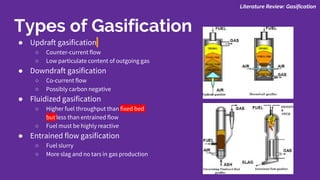

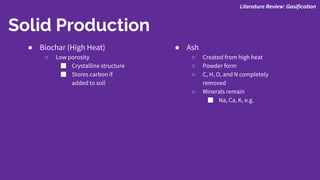

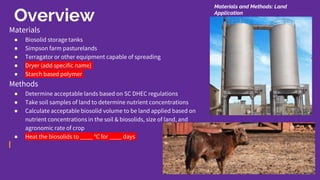

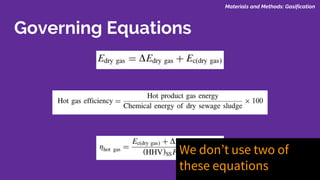

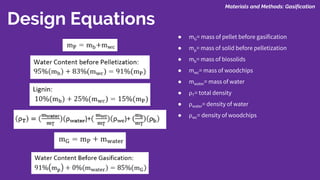

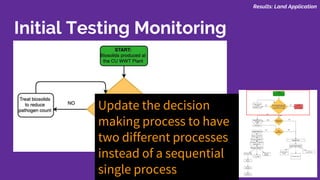

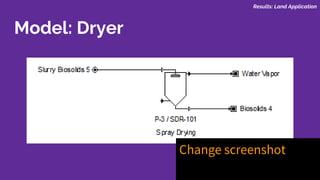

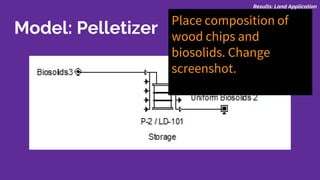

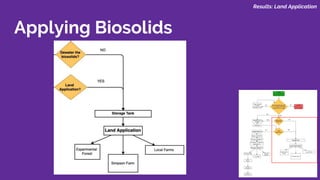

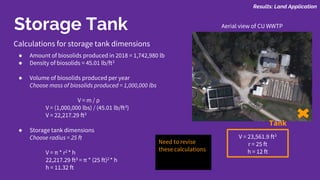

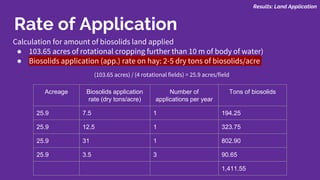

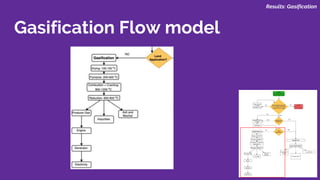

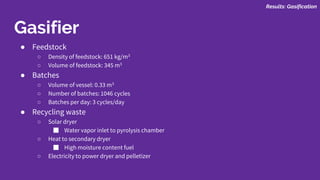

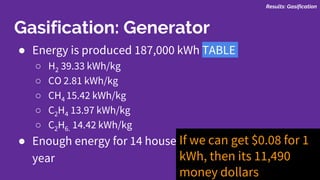

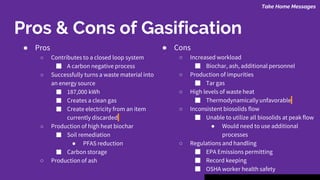

This document outlines a student capstone project to develop viable pathways for utilizing biosolids from Clemson University's wastewater treatment plant. It provides background on biosolids and their potential uses, including land application and gasification. The objectives are to review relevant regulations, sample biosolids from CU to determine pathogen levels, and design land application and gasification processes. Literature on the carbon, nitrogen, and phosphorus cycles is reviewed, as well as regulations for land application and types of gasification.