The document summarizes the Rotoform® pastillation process developed by Sandvik for solidifying fertilizers like urea. Key points:

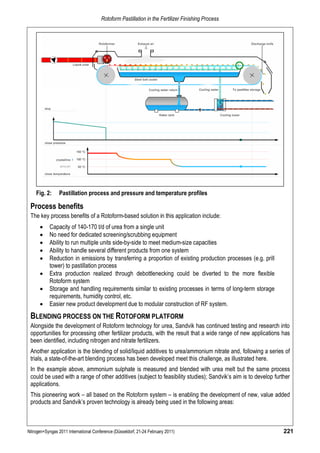

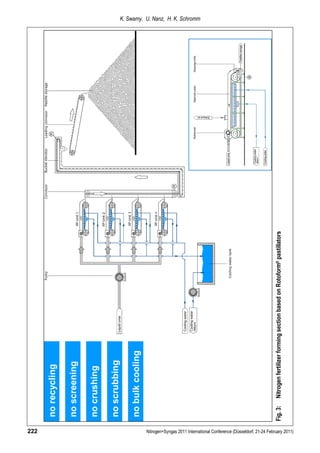

1) The Rotoform® process involves depositing liquid fertilizer droplets onto a moving steel belt where they solidify into pastilles indirectly via water spray, avoiding contamination.

2) It has been commercialized successfully for technical-grade urea production.

3) Benefits include lower emissions, modular design, and capacity of 140-170 tonnes per day from a single unit.