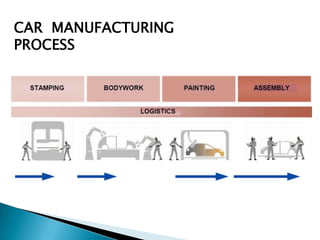

The document outlines the car manufacturing process. It involves several steps like arc welding to join metal components using electric arcs. The white body is then sent to the paint department where it undergoes a multi-step painting process taking 1.5-2 days. Next, the car body moves to the assembly line where it is assembled over 65 stations in about 2 hours. Key steps in assembly include installing the engine, seats, wheels and other components at different stations along the moving platform. The car then undergoes extensive quality checks before final completion.