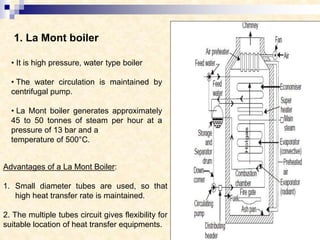

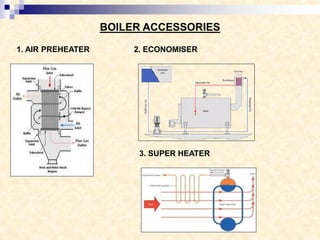

This document provides information about high pressure boilers. It begins with an introduction and definition of boilers. It then discusses the classification of boilers, including factors such as relative position of hot gases and water, geometric orientation, method of firing, and pressure of steam. The document focuses on high pressure boilers, providing examples such as the Lamont boiler and features of high pressure boilers. It also discusses boiler mountings and accessories, feed water treatment, draught systems, chimney design, and concludes with a boiler heat balance sheet.