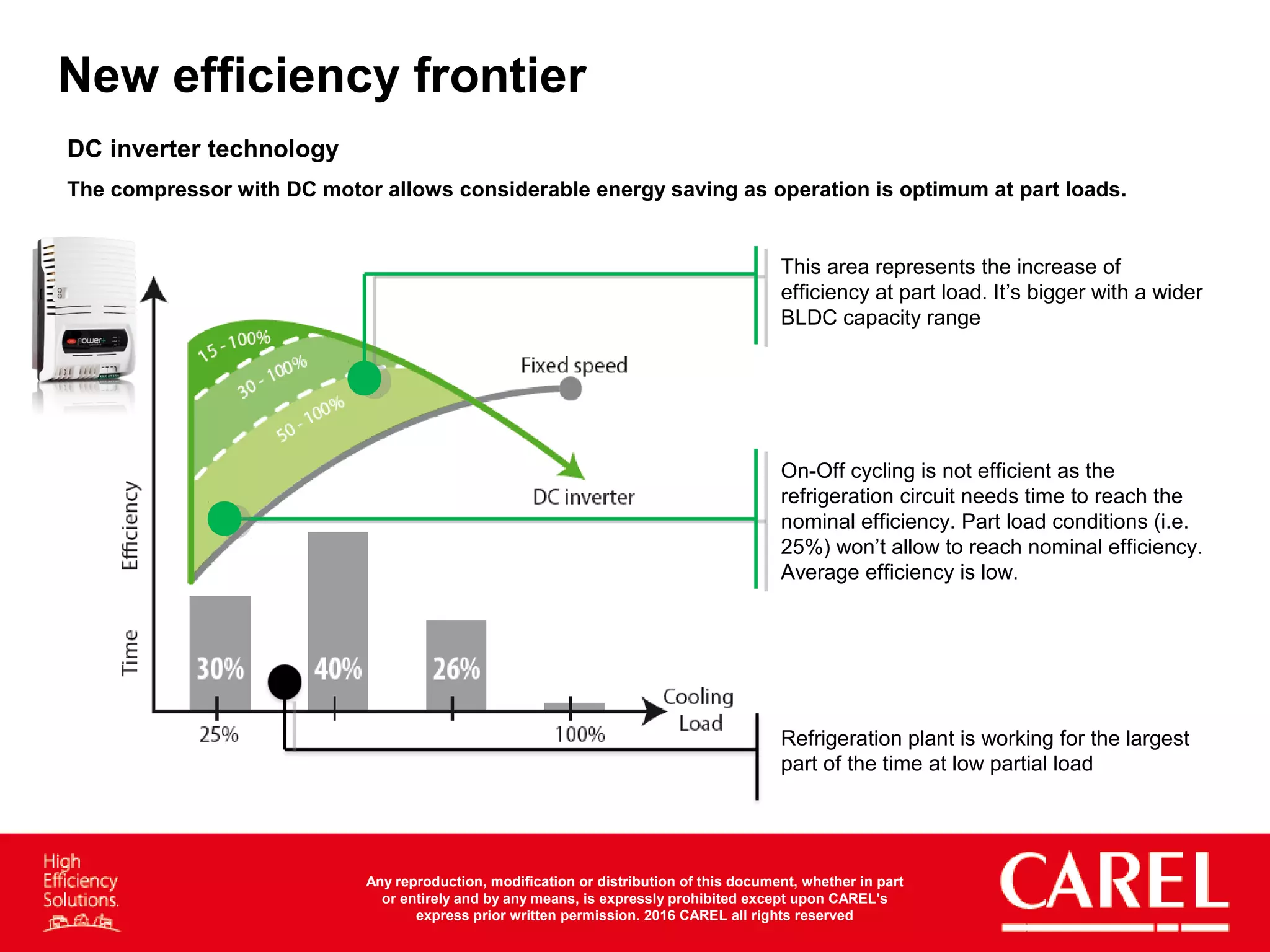

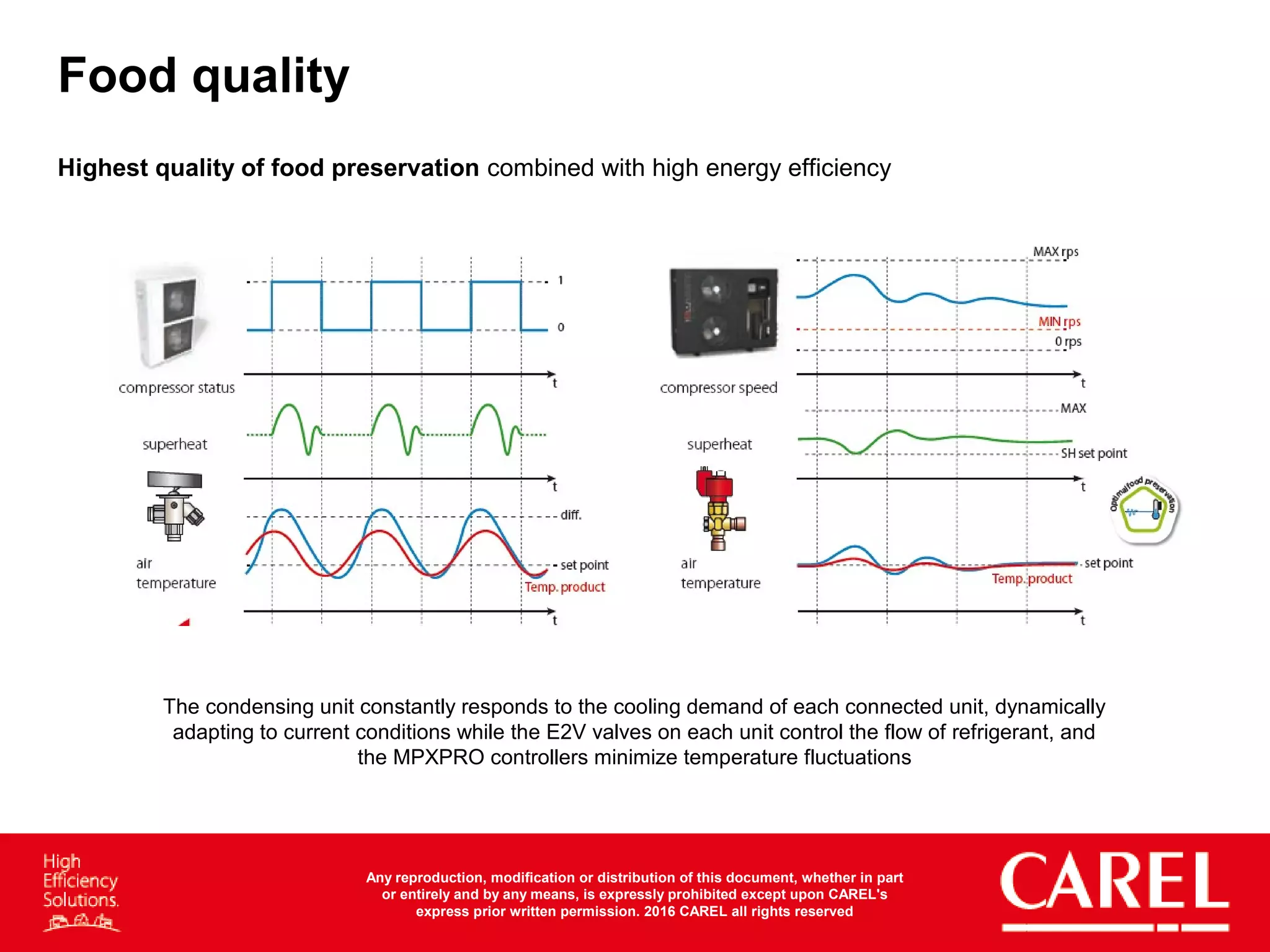

This document discusses CO2 transcritical DC condensing units and their compliance with various energy efficiency regulations in Europe, the USA, Japan, and China. It highlights the benefits of using DC inverter technology for energy savings, stable temperature control, and reduced system downtime, while ensuring optimum food preservation. The importance of advanced control algorithms and real-time monitoring for enhancing system performance is also emphasized.