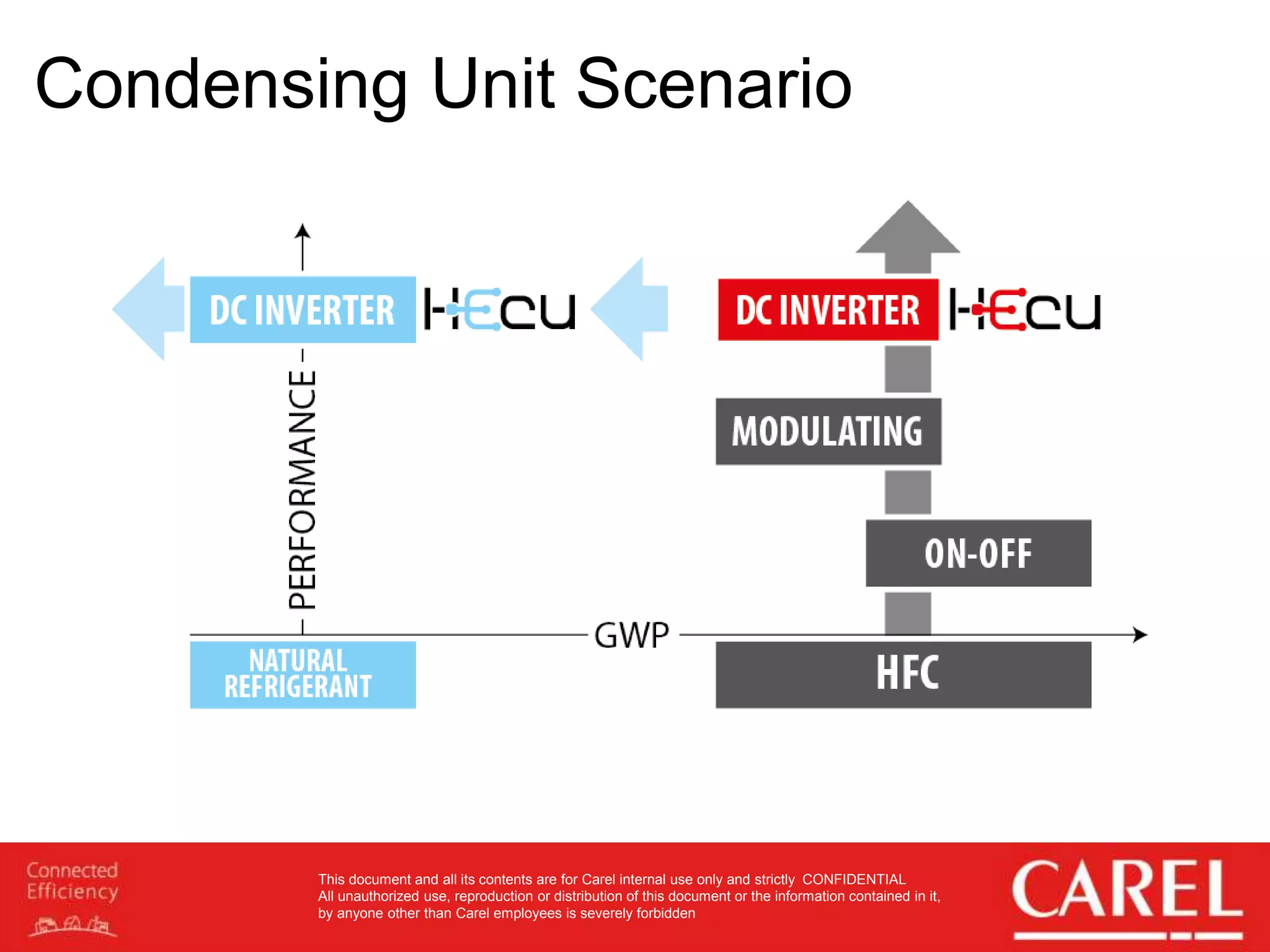

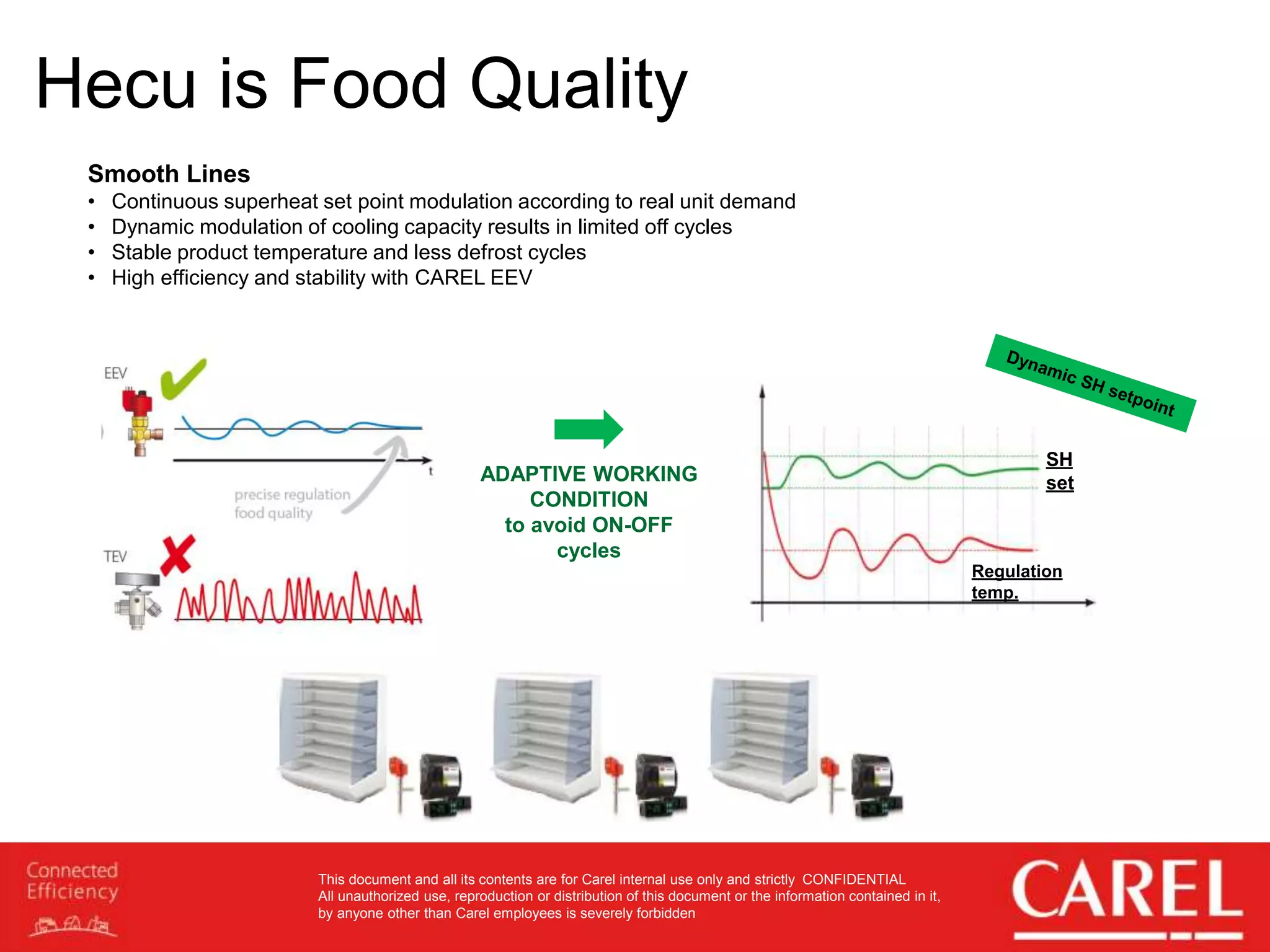

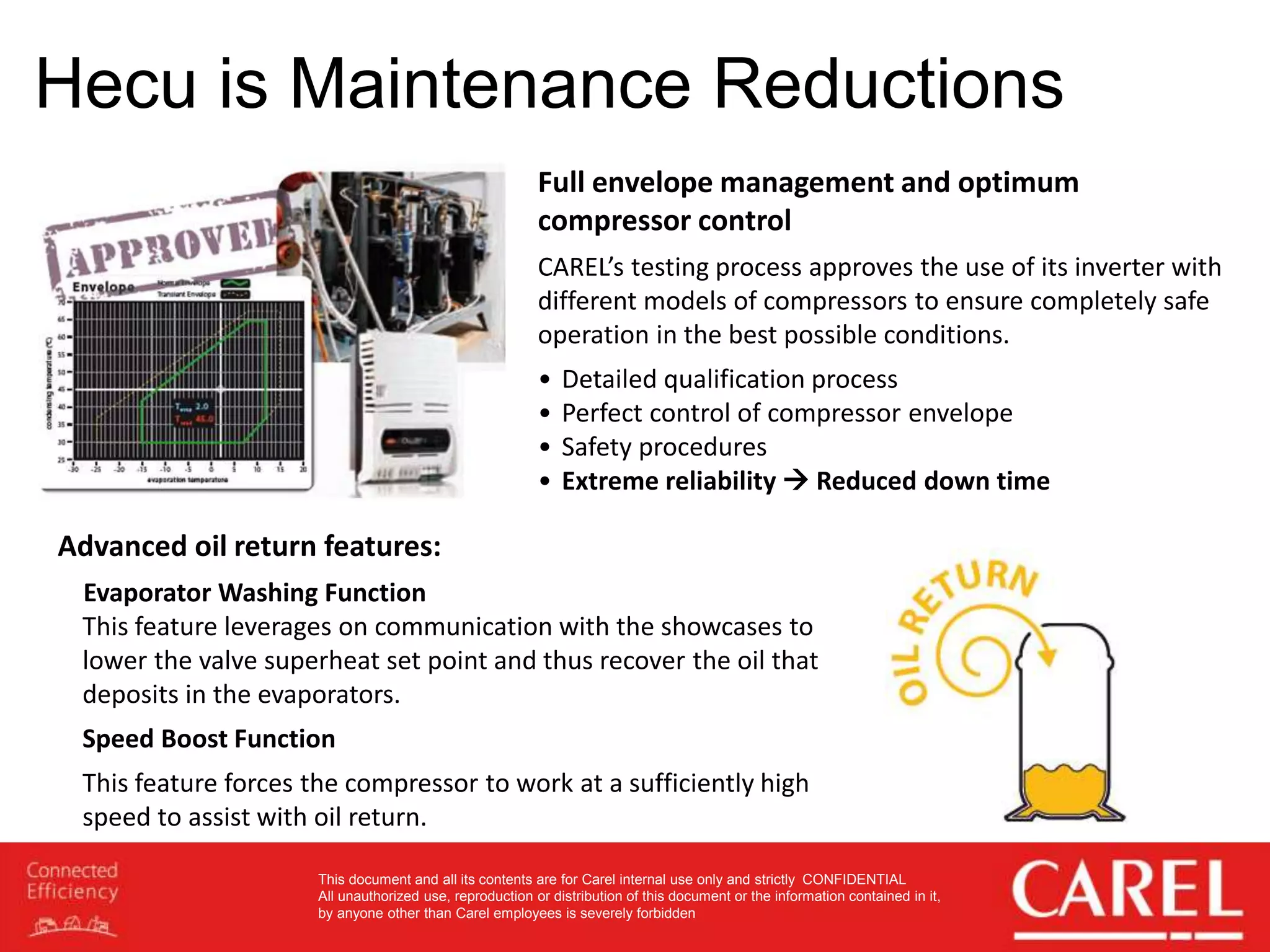

The document outlines CAREL's high efficiency condensing units (HECU), emphasizing their internal usage confidentiality and the advanced features that enable optimal performance and energy savings. Key components include DC inverter-driven compressors, electronic expansion valves, and advanced monitoring systems, all designed for superior food preservation and reduced maintenance. The HECU system supports dynamic cooling, real-time adjustments, and easy setup, making it suitable for both medium and low-temperature applications.