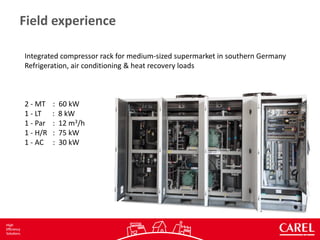

This document discusses an integrated CO2 system for refrigeration, air conditioning, and heat recovery installed in a supermarket in southern Germany. It includes:

1. Medium and low temperature compressors, a parallel compressor, heat exchangers, and valves to control the transcritical and flash gas processes.

2. The system is controlled as a single unit to reduce installation costs and space needs while improving efficiency through more precise control and optimization of refrigeration, air conditioning, and heat recovery loads.

3. Data is collected in real-time to calculate COP and divide total energy consumption between the different applications to evaluate system performance under varying operating conditions.

![How to divide total energy consumption between REF – AC – HR?

Compressor power consumption [kW]

• PMT : Medium temperature compressors

• PLT : Low temperature compressors

• PPC : Parallel compressors

• PGC : Gas cooler

Integration

Heat transfer

• QAC : Air conditioning heat

• QHR : Heat recovery heat

One unit providing REF+AC+HR](https://image.slidesharecdn.com/atmoeu2013-carel-malimpensa-160906081720/85/Integrated-CO2-systems-for-warm-climates-5-320.jpg)

![Integration

Temperatures

Pressures

Comps data

Entalpies

Qualities

COPHR

COPAC

COPREF

PHR PAC

PREF

Air conditioning mode

Heat Reclaim mode

Higher gas cooler pressure

Higher quality of vapour

𝐶𝑂𝑃 𝐻𝑅 𝑂𝑁

𝐶𝑂𝑃 𝐻𝑅 𝑂𝐹𝐹 [𝑇]

=

𝑃 𝐻𝑅 𝑂𝑁

𝑃 𝐻𝑅 𝑂𝐹𝐹

Higher quality of vapour

Mass refrigerant flow 𝑚 𝐴𝐶](https://image.slidesharecdn.com/atmoeu2013-carel-malimpensa-160906081720/85/Integrated-CO2-systems-for-warm-climates-7-320.jpg)

![00

10

20

30

40

50

60

10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35

PowerConsumption[kW]

Outside temperature [°C]

Power consumption vs Temperature

Booster with Flash Valve Booster with Parallel compressor

Parallel compressor

enabled to run only when

outside temperature higher

than 15°C

Warm Climates

-15%](https://image.slidesharecdn.com/atmoeu2013-carel-malimpensa-160906081720/85/Integrated-CO2-systems-for-warm-climates-9-320.jpg)

![0

20

40

60

80

100

120

140

160

180

200

Munich [8°C] Venice [13°C] Palermo [18°C]

PowerConnsumption[kW]

Energy consumption comparison

Booster with Flash Valve Booster with Parallel Comp

-4%

-10%

Warm Climates

-7%](https://image.slidesharecdn.com/atmoeu2013-carel-malimpensa-160906081720/85/Integrated-CO2-systems-for-warm-climates-10-320.jpg)

![0

20

40

60

80

100

120

140

160

180

200

Munich [8°C] Venice [13°C] Palermo [18°C]

PowerConnsumption[kW]

Energy consumption comparison

Booster with Flash Valve Cascade R134a/CO2 Booster with Parallel Comp

Warm Climates

-10%

-6%

≈](https://image.slidesharecdn.com/atmoeu2013-carel-malimpensa-160906081720/85/Integrated-CO2-systems-for-warm-climates-11-320.jpg)