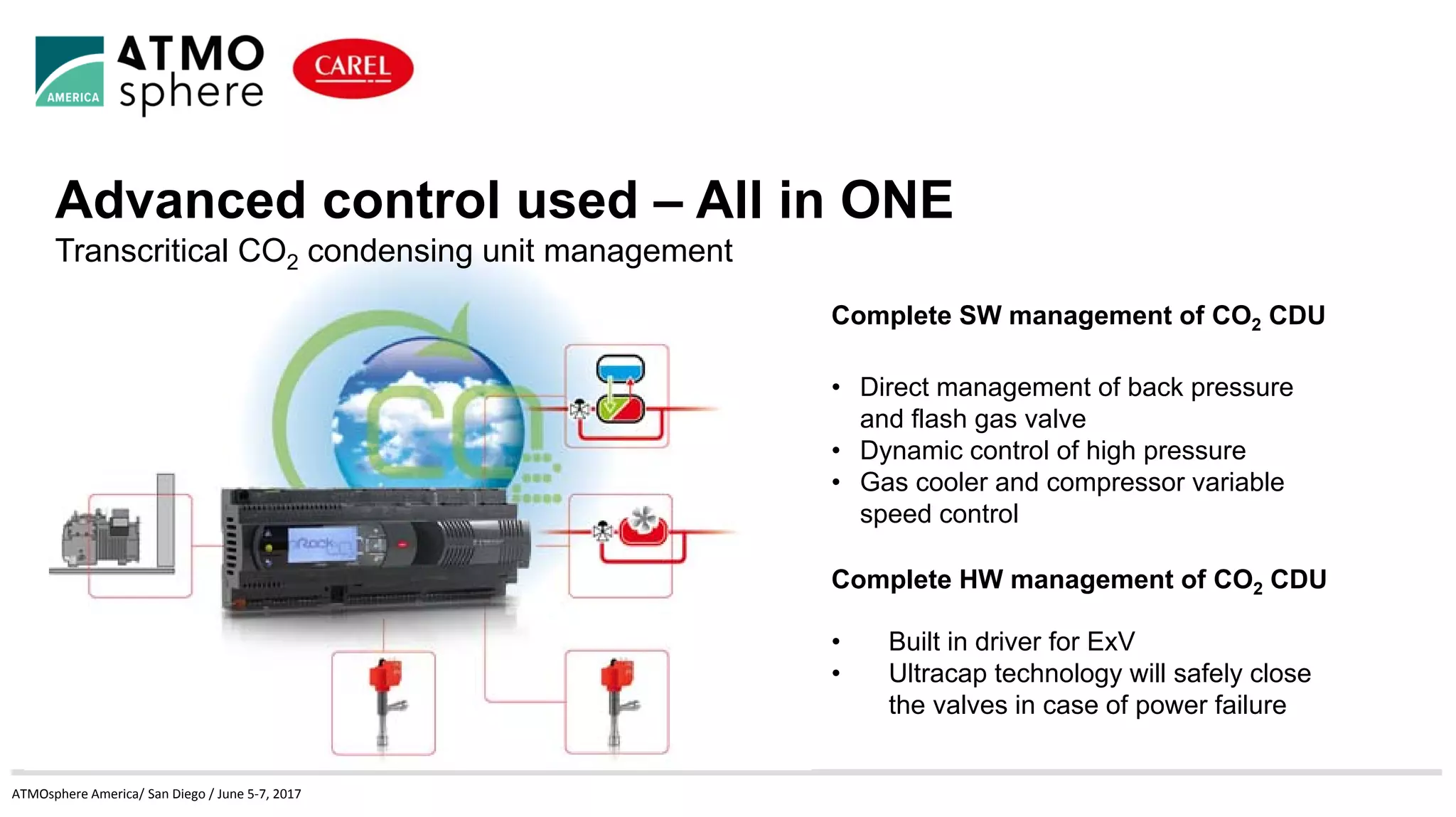

The document discusses the viability and features of CO2 refrigeration technology, with a survey indicating strong support from OEMs and consultants in North America. It highlights a compact CO2 transcritical controller and advanced management systems for efficiency in commercial refrigeration applications. Additionally, it notes the importance of technology neutrality, scalability, and simplicity for improving CO2 performance across varying climates.