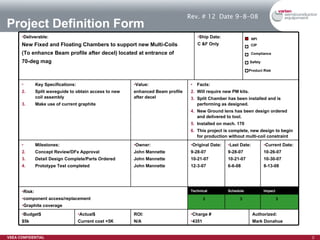

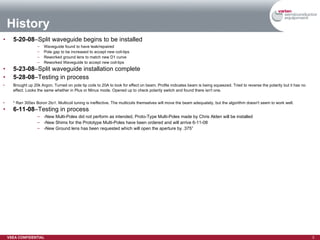

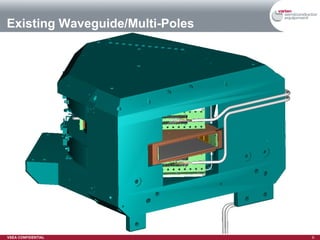

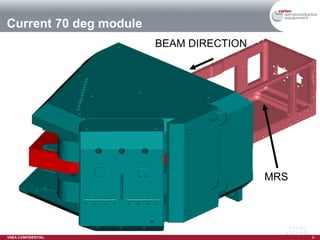

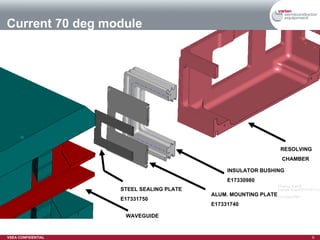

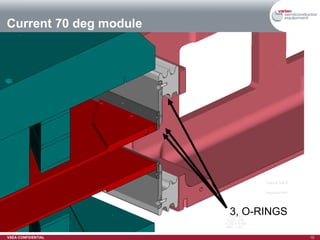

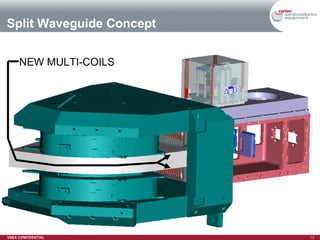

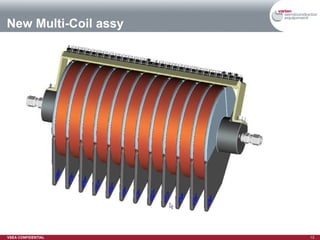

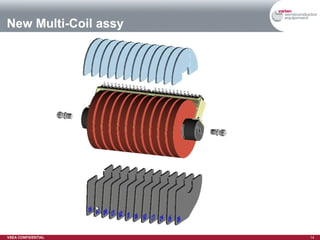

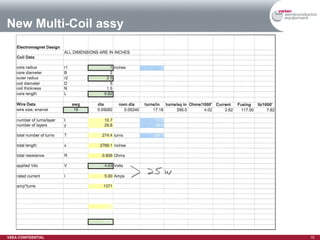

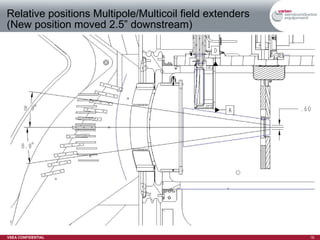

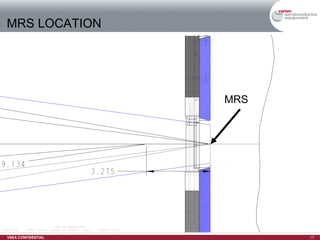

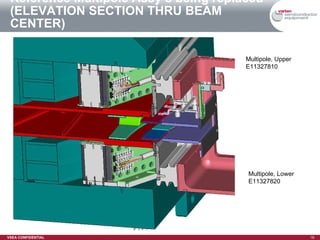

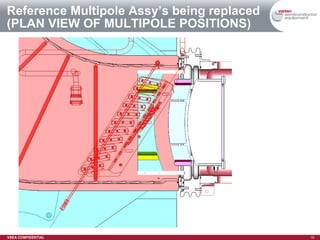

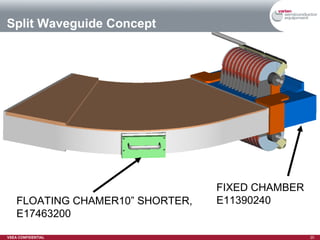

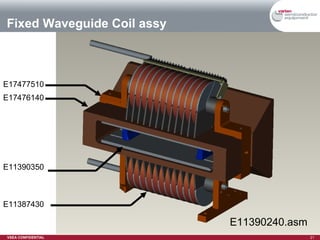

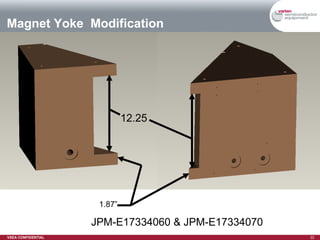

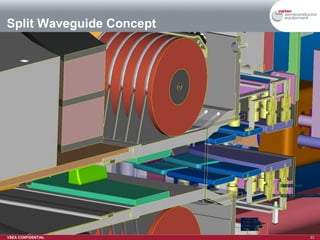

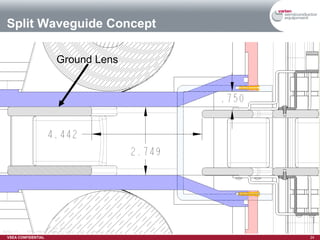

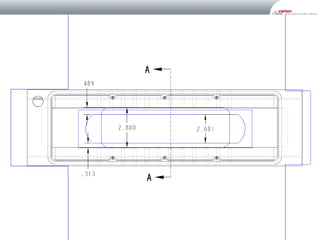

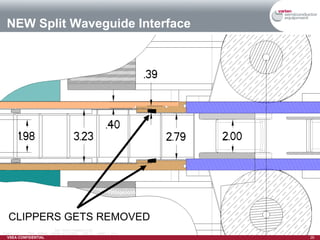

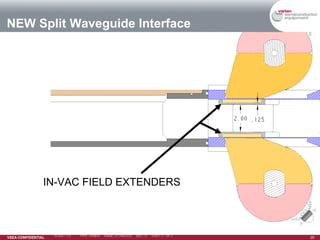

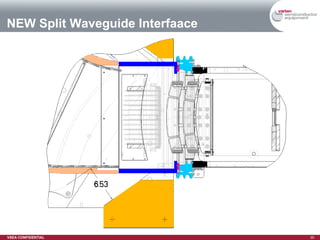

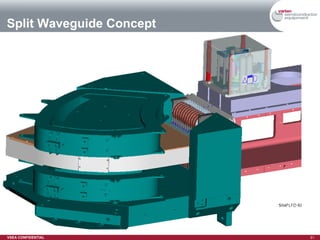

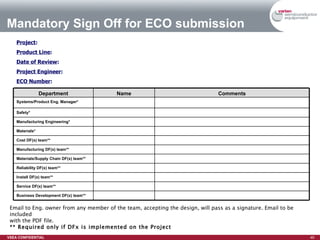

This document provides a project definition and design details for a split waveguide to be installed on an HCD-70 ion beam system. The split waveguide will allow access to new multi-coil assemblies intended to enhance the beam profile after deceleration. Key aspects of the design include splitting the existing waveguide into fixed and floating chambers, installing new multi-coil assemblies with field extending bars, and modifying related components like the ground lens and magnet yoke. Testing of prototypes indicated some tuning issues with the new design which require further iterations.