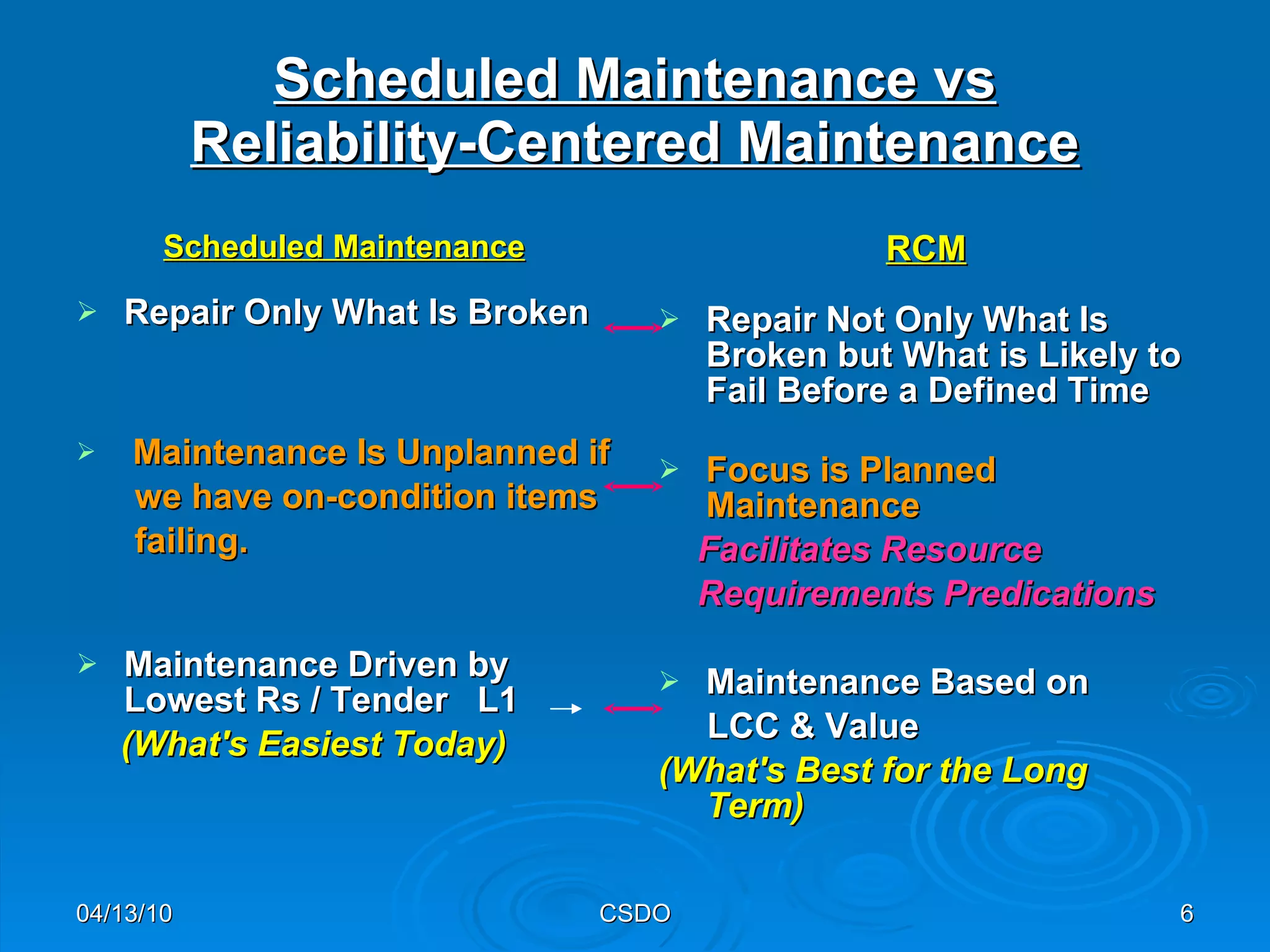

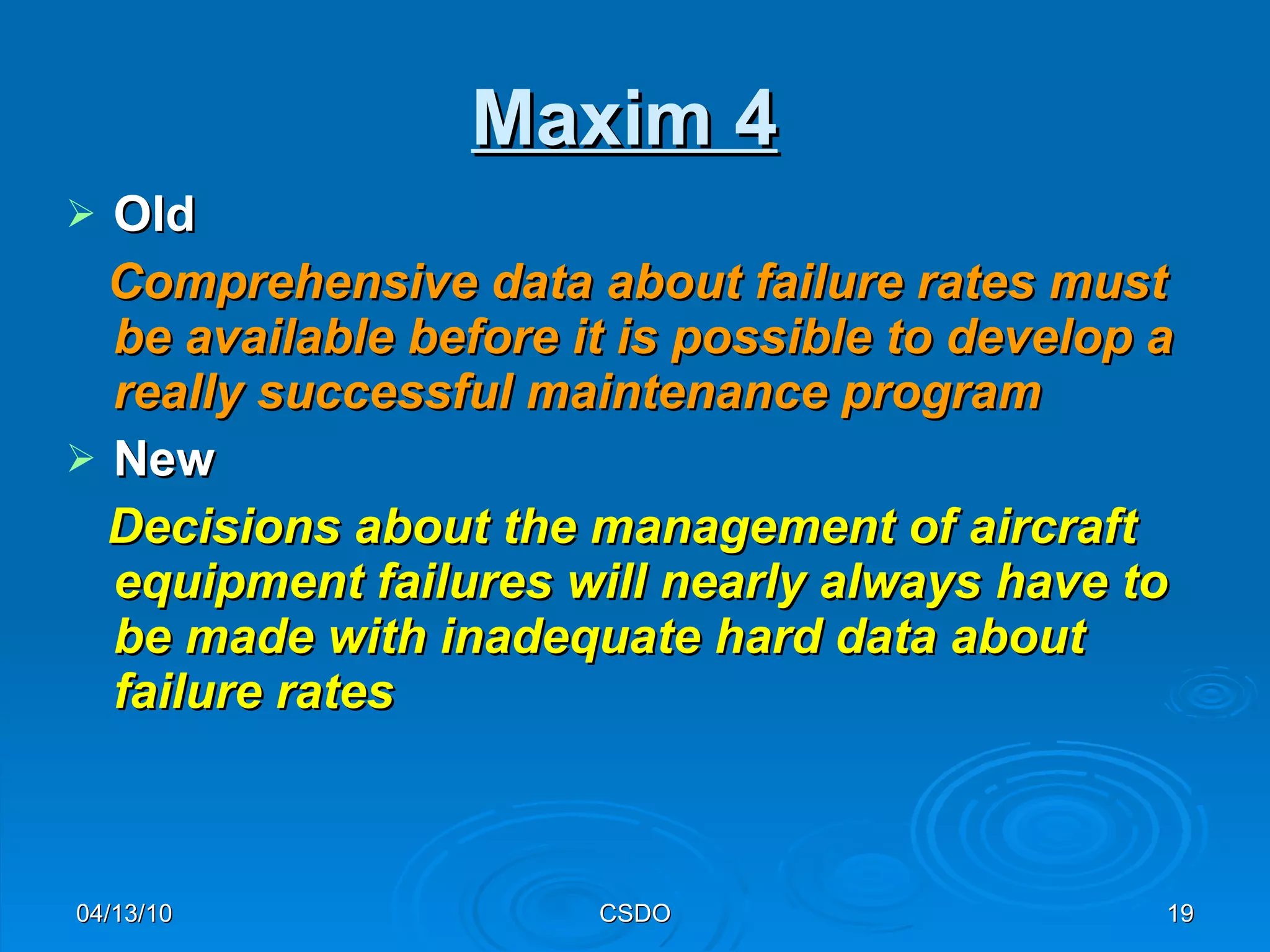

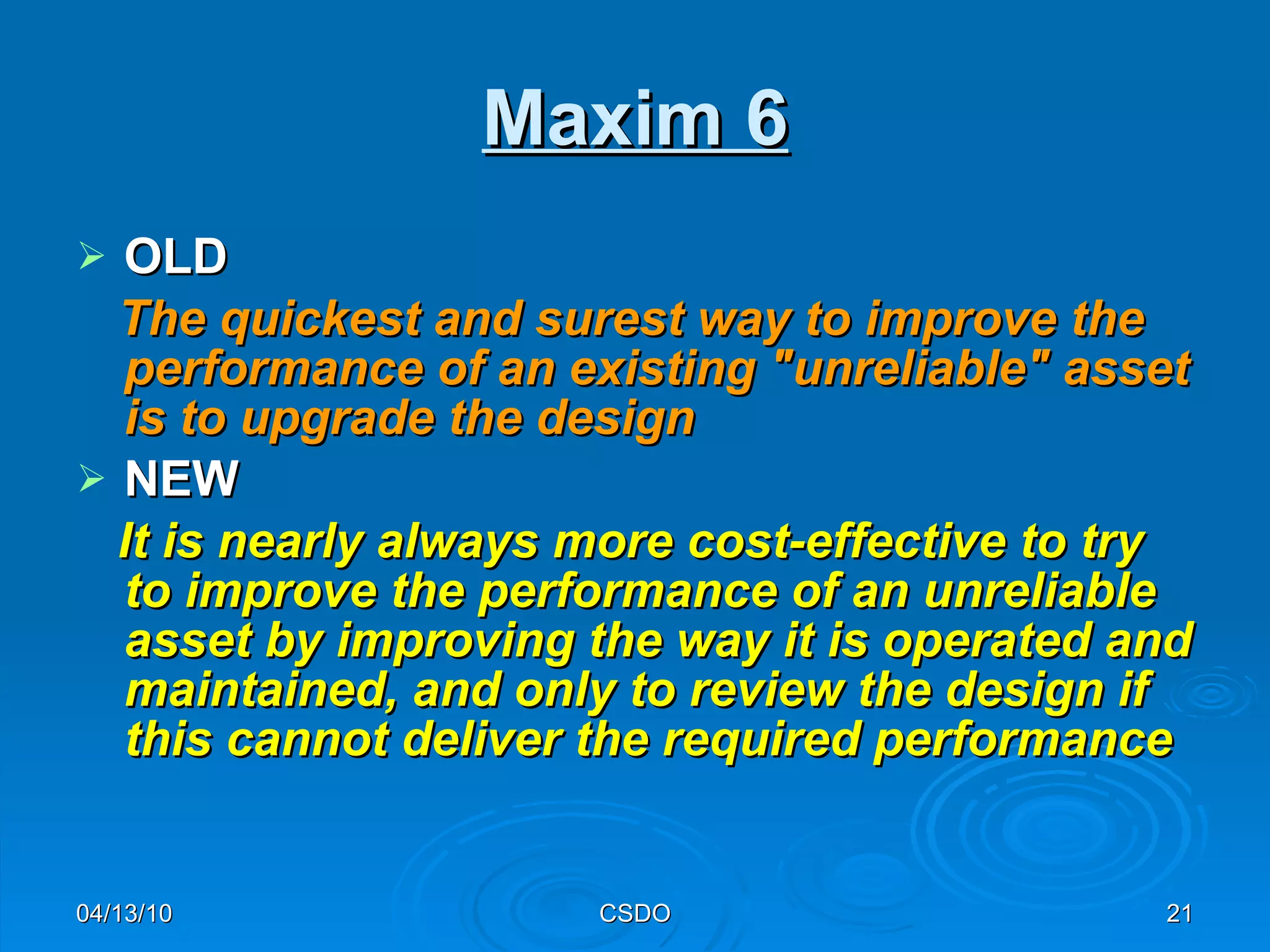

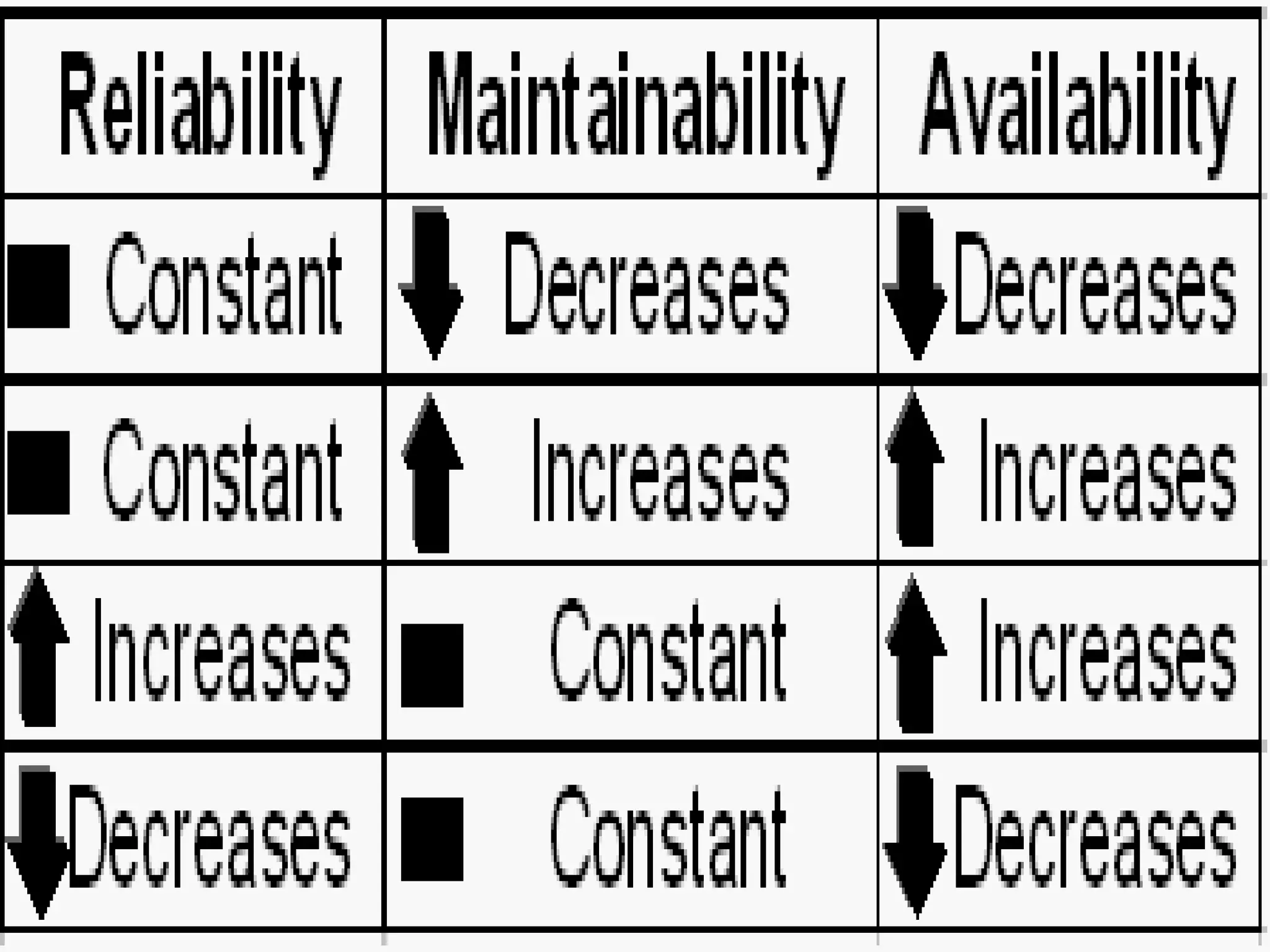

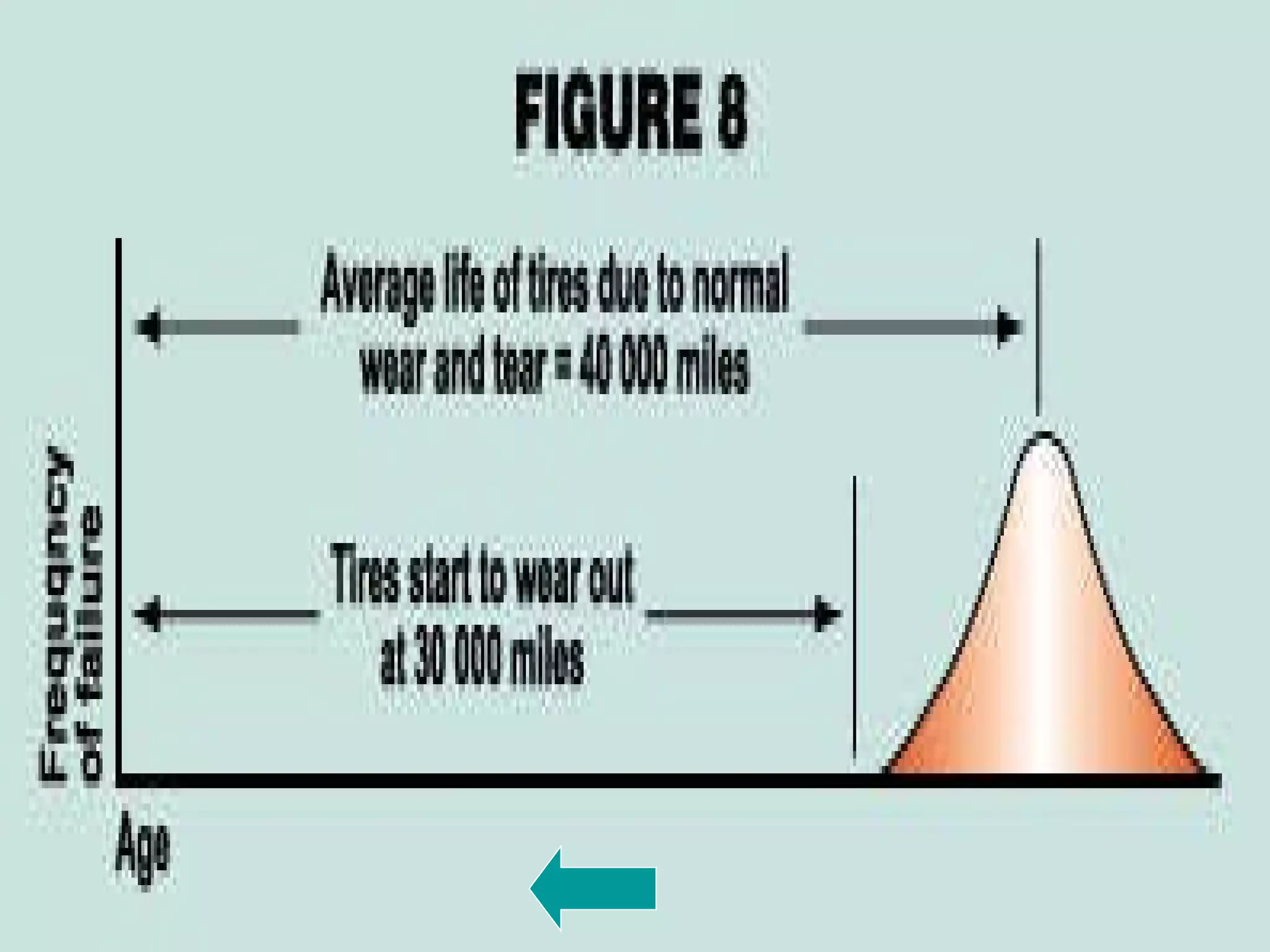

The document discusses the evolution of aircraft maintenance over four generations. The fourth generation focuses on failure elimination through techniques like root cause analysis and reliability-centered maintenance. It also discusses improving maintainability at the aircraft design stage to reduce maintenance needs and costs. The fifth generation aims for increased reliability, maintainability and sustainability with a focus on designing for ease of maintenance.