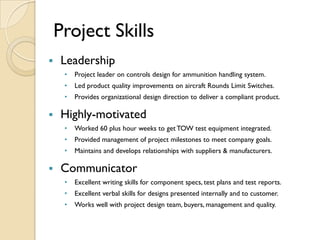

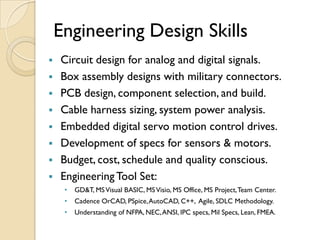

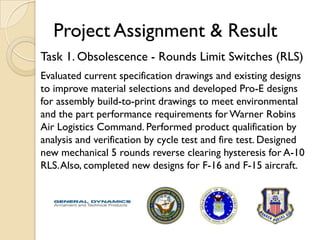

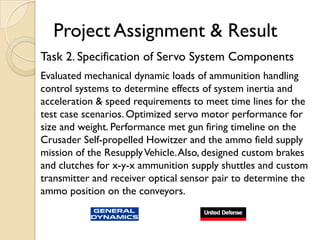

Greg Sleeper has over 20 years of experience in electrical engineering, systems design, software development, quality assurance, and test engineering. He has worked on projects for commercial industry, military contracts, and academic medical research. Some of his project experiences include designing ammunition handling systems, aircraft components, military interface cables, software test plans, and repairing test equipment. He is skilled in circuit design, PCB design, mechanical design, programming, and project management.