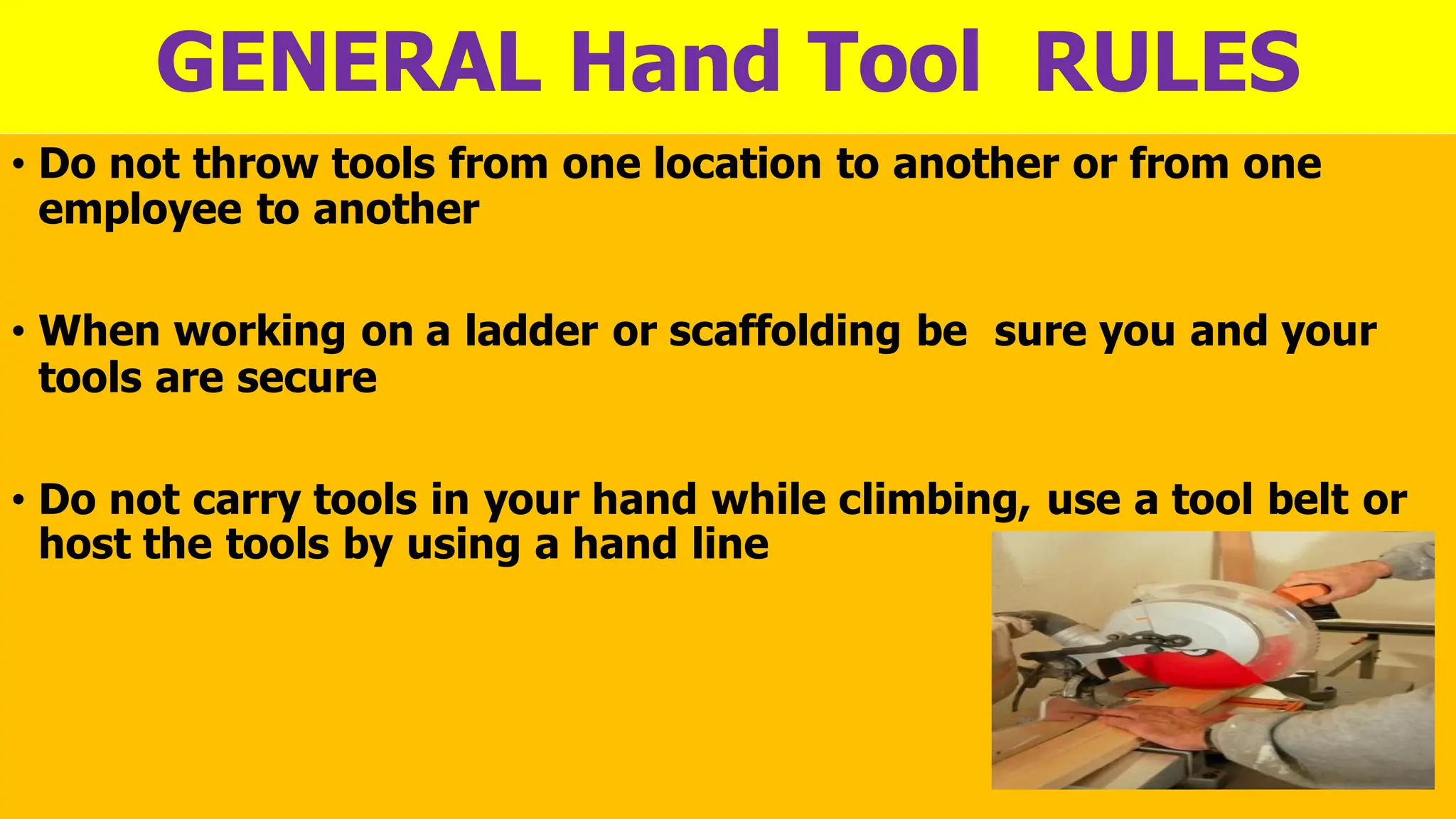

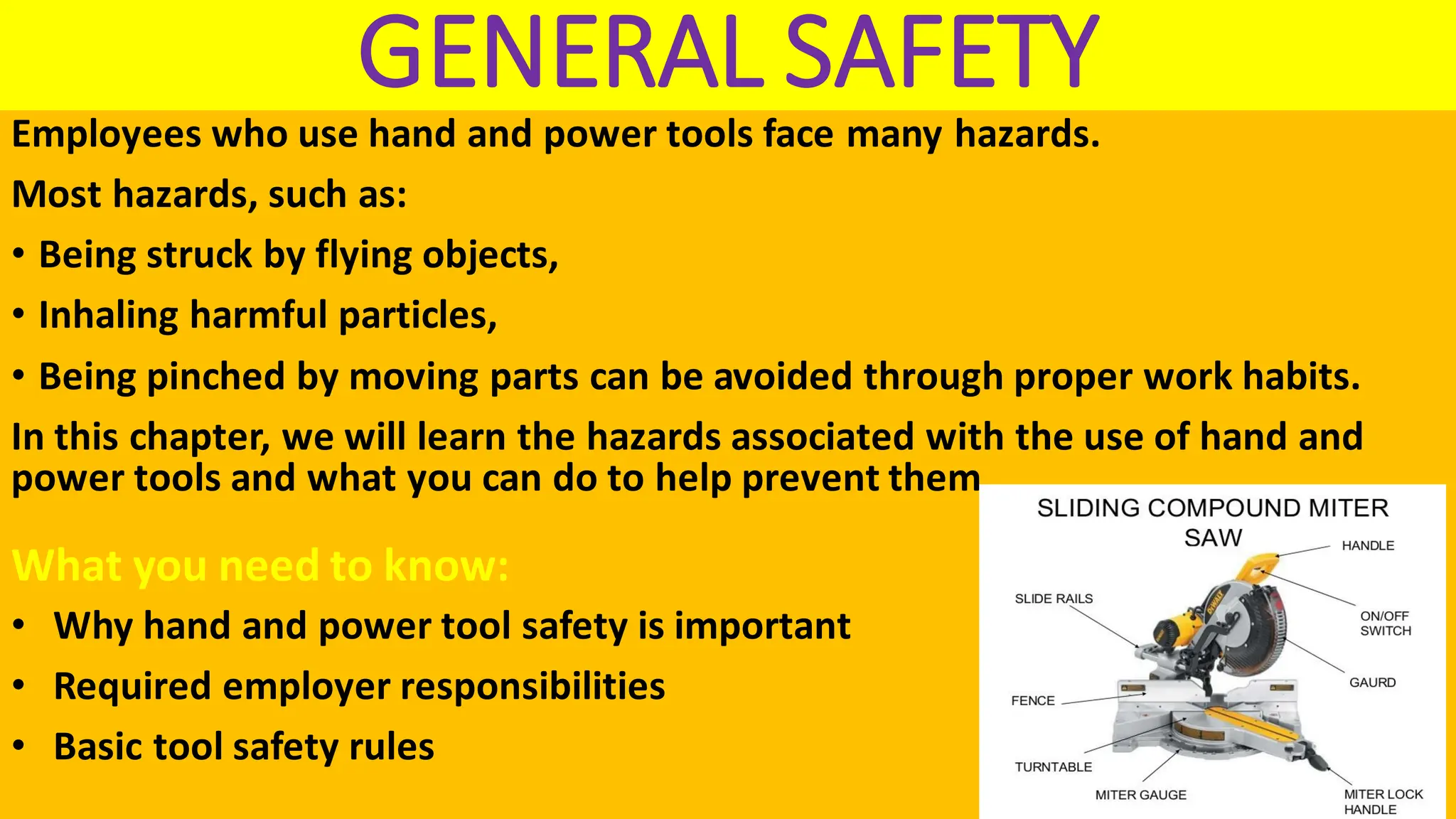

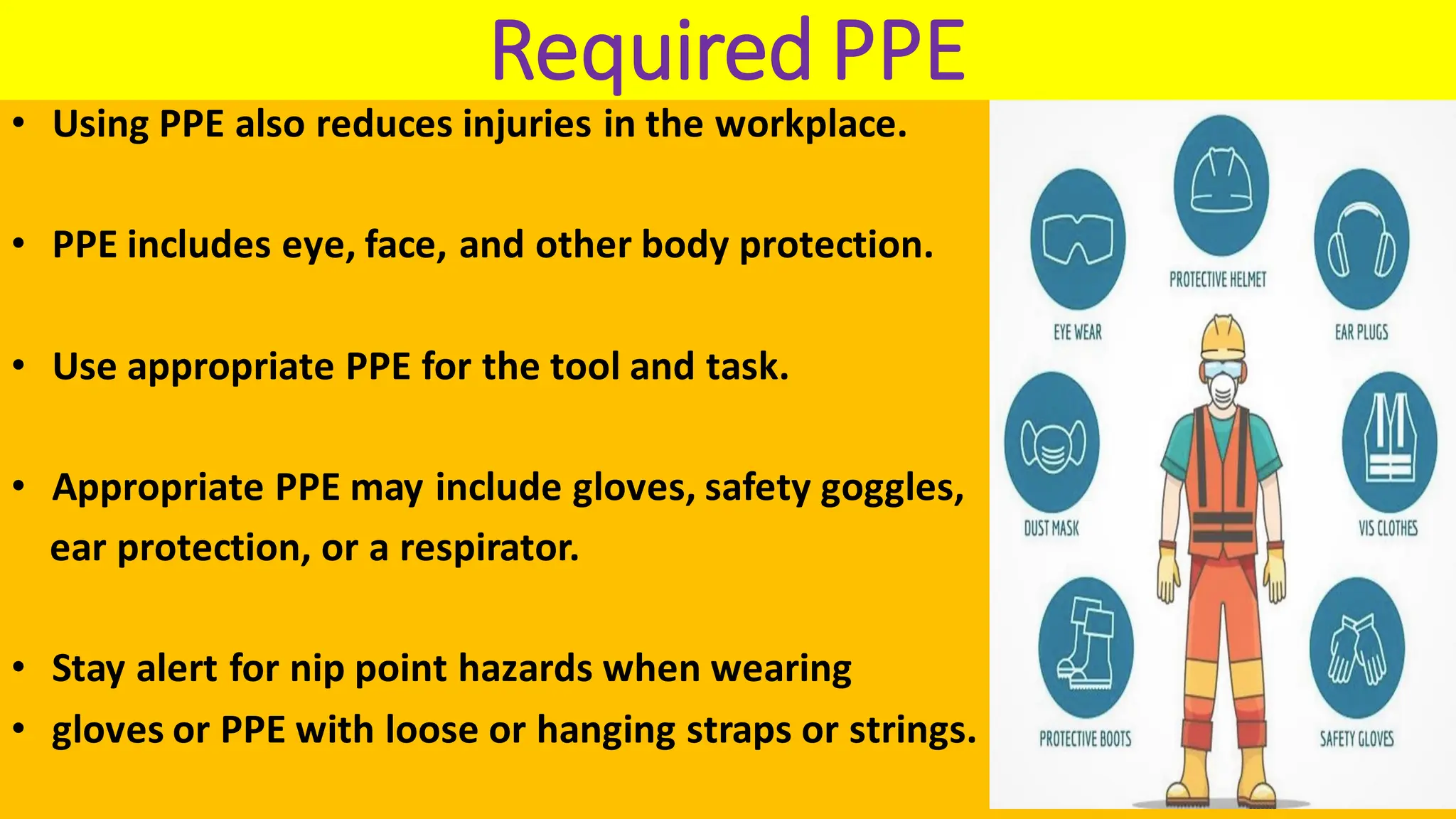

The document outlines safety guidelines for using hand and power tools, emphasizing the importance of proper maintenance, training, and the use of personal protective equipment (PPE). It details specific safety rules for various types of tools, the hazards associated with them, and the responsibilities of both employers and employees in ensuring workplace safety. Regular inspections and adherence to manufacturer instructions are crucial for preventing accidents in construction environments.