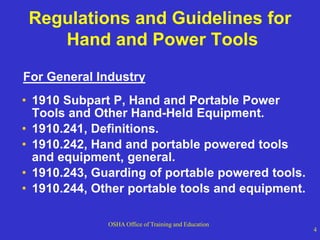

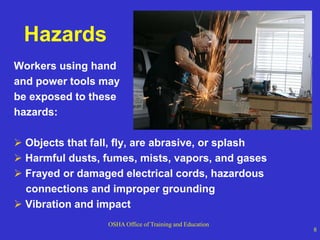

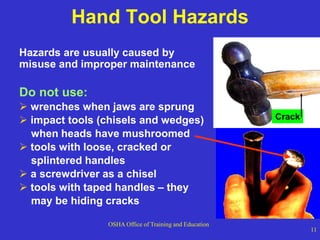

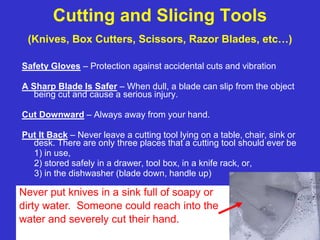

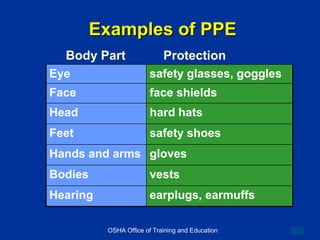

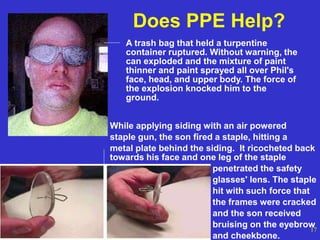

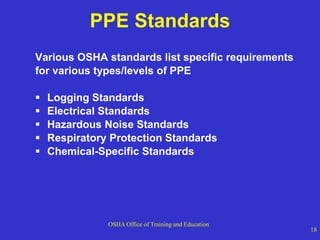

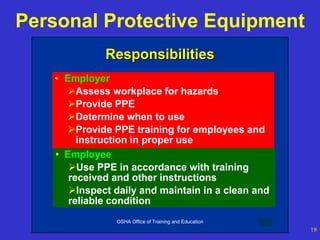

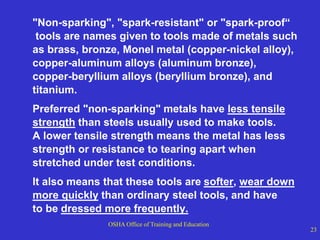

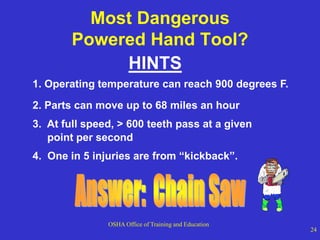

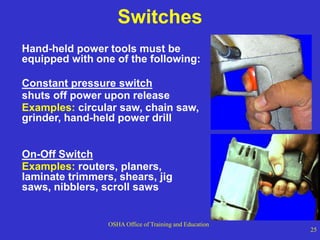

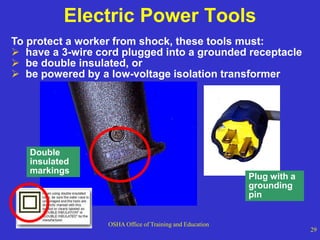

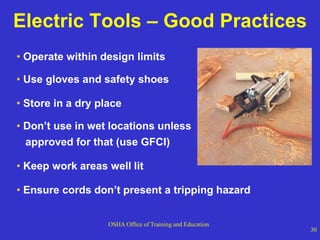

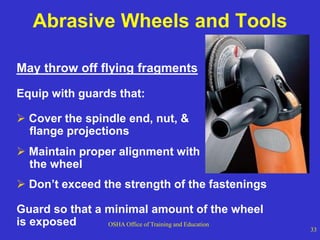

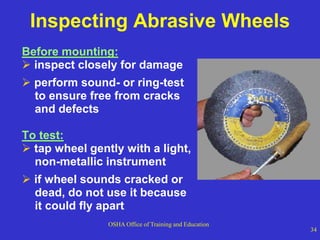

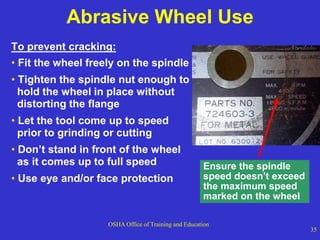

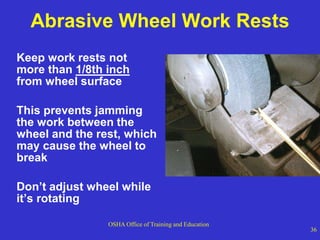

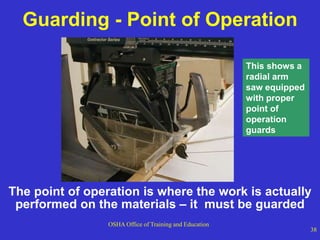

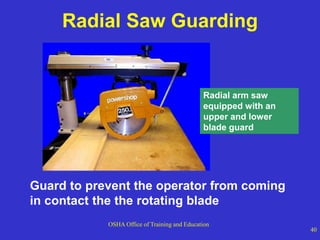

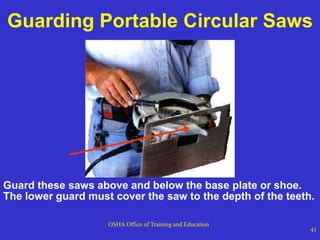

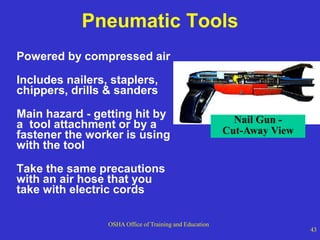

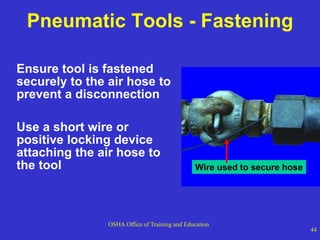

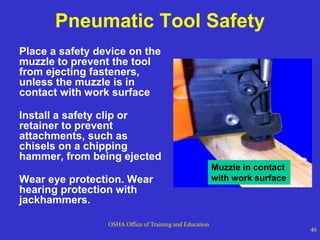

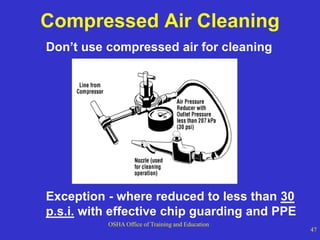

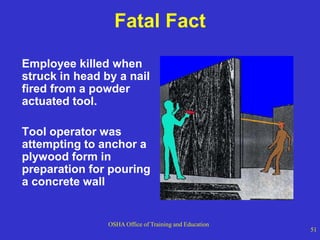

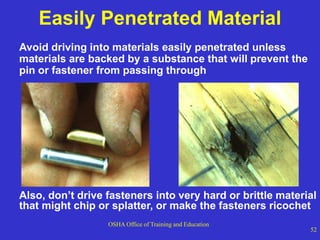

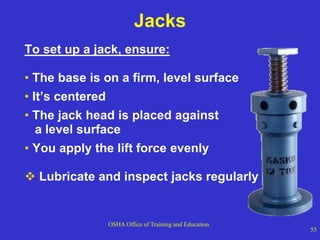

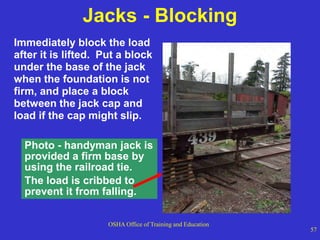

The document outlines safety guidelines and regulations for hand and power tools as stipulated by OSHA, including proper maintenance, personal protective equipment (PPE), and specific safety procedures for various tools. It emphasizes the importance of tool safety to prevent injuries such as electric shocks, cuts, and ergonomic issues, while detailing specific precautions and responsibilities for both employers and employees. The content covers a wide range of tools, including pneumatic and liquid fuel tools, and highlights the need for proper training and safety measures in the workplace.