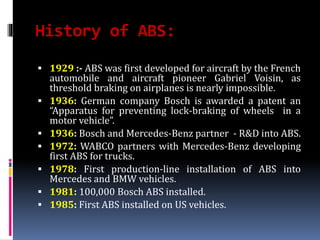

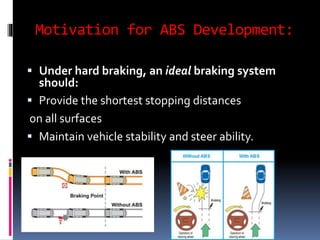

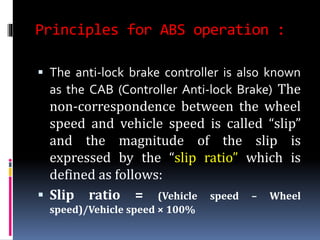

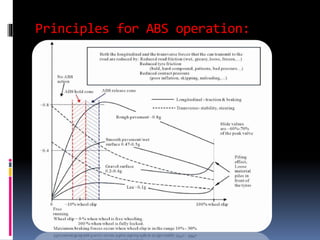

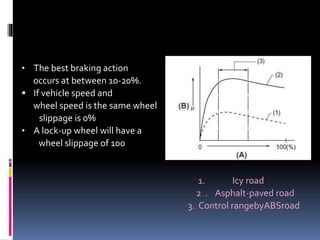

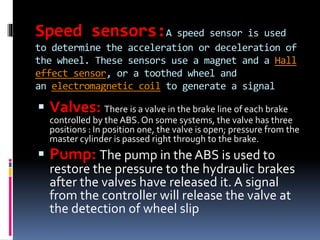

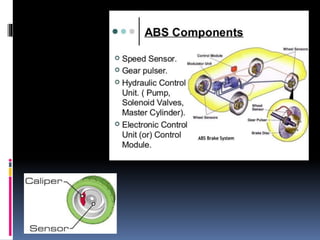

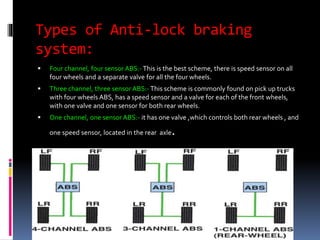

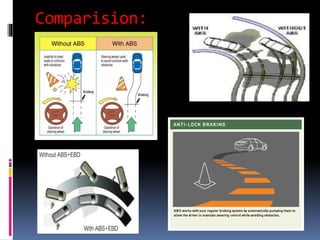

The document discusses anti-lock braking systems (ABS). It begins by introducing ABS and explaining that it prevents wheels from locking up during braking, allowing the driver to maintain steering control. It then covers the history of ABS development from 1929 to present day, where almost all new cars have the technology. The principles and components of ABS are described, including speed sensors, valves, a pump, and controller that regulate brake fluid pressure to each wheel to optimize braking performance. Finally, the advantages of ABS in maintaining vehicle stability and control during braking are highlighted, though the technology does increase vehicle costs.