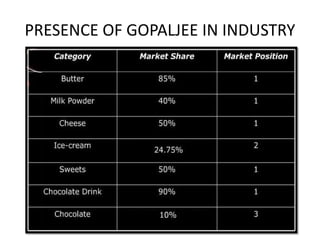

Gopaljee is a large dairy company in India with an extensive supply chain network.

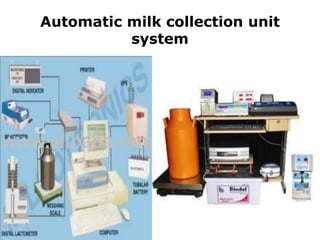

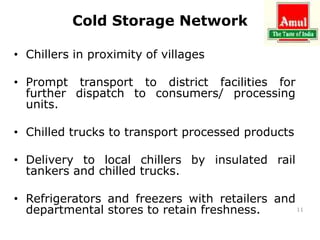

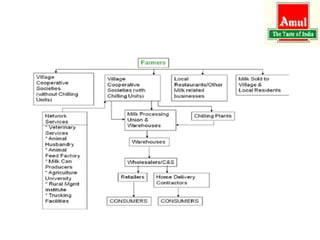

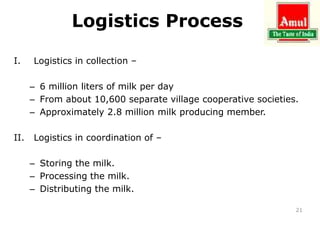

The supply chain involves procuring milk directly from farmers through a village cooperative society system. Over a thousand farmers sell milk daily at local centers, where it is weighed, tested, and farmers are promptly paid based on fat content. The milk is then quickly transported in chilled trucks to processing plants.

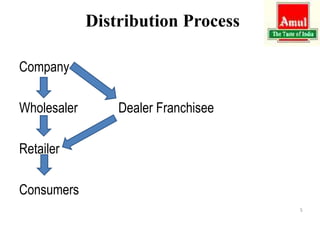

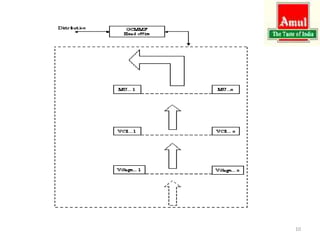

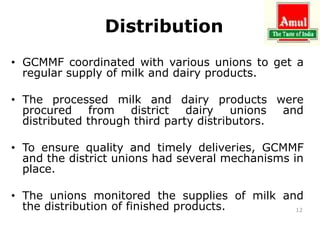

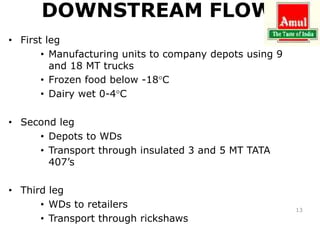

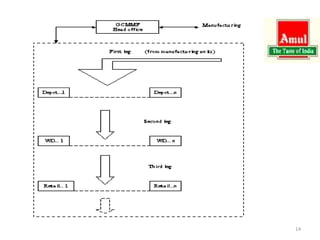

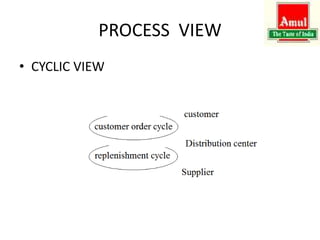

Gopaljee then distributes processed dairy products through a multi-level network of depots, wholesalers, distributors and retailers to consumers. They aim to ensure quality and timely deliveries while minimizing inventory through direct procurement and established transportation infrastructure.