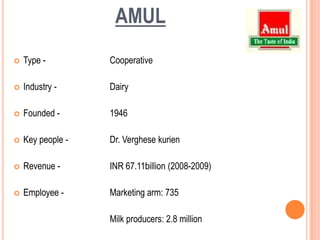

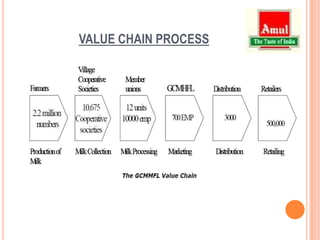

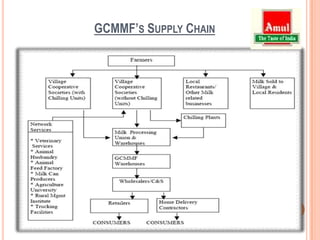

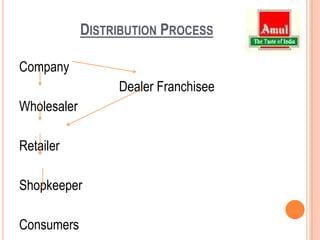

1) Amul is a dairy cooperative founded in 1946 that is owned by 3 million milk producers in Gujarat, India. It manages the entire dairy value chain from procurement to processing to distribution.

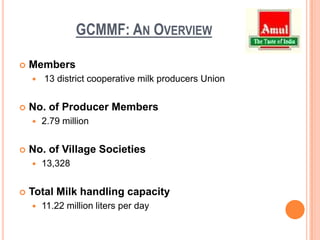

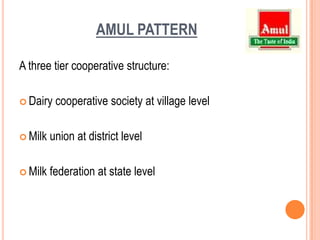

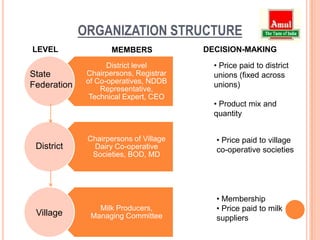

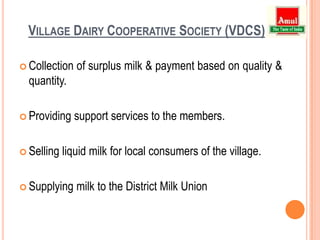

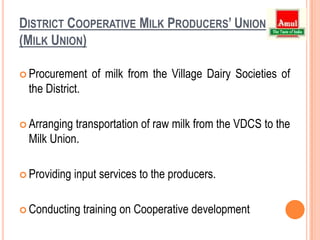

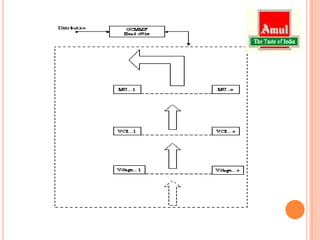

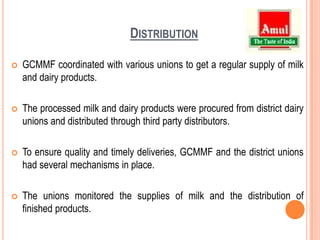

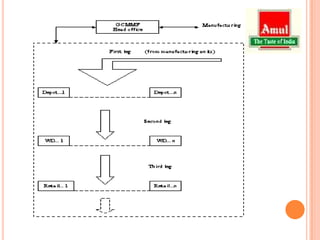

2) Amul uses a 3-tier cooperative structure comprising village dairy cooperative societies, district milk unions, and a state milk federation to efficiently manage its large network for collecting and processing milk.

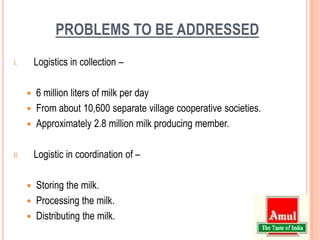

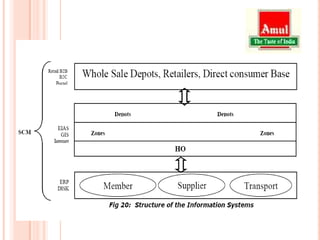

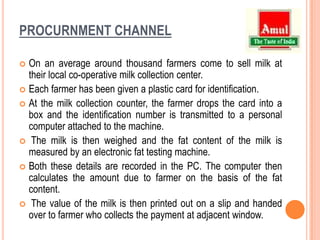

3) Amul has leveraged technology and implemented an ERP system to automate its operations, improve transparency, and reduce processing times. This has enabled it to efficiently handle the collection of 6 million liters of milk per day from thousands of villages across Gujarat.