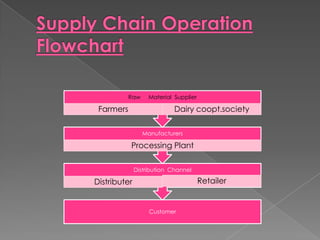

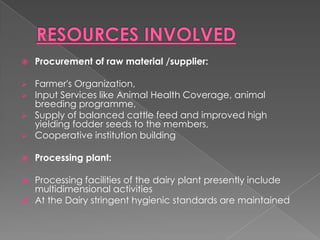

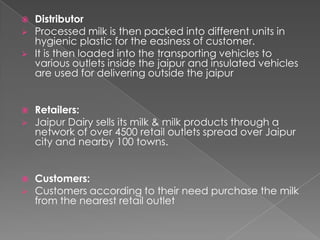

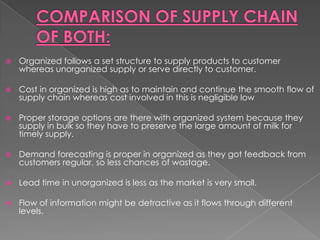

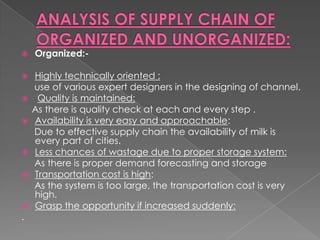

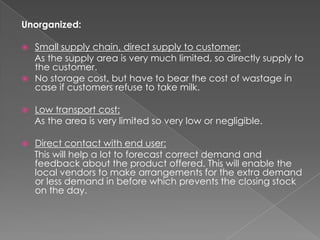

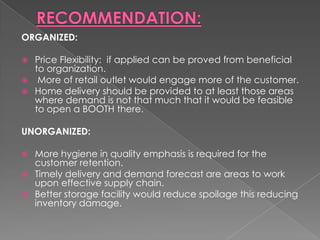

The document describes the supply chain of a dairy cooperative society in Jaipur, India. It discusses the procurement of raw materials from farmers, the processing plant, distribution through distributors and retailers, and delivery to customers. It also contrasts the organized supply chain system used by the cooperative with the traditional unorganized local milkman system, noting differences in structure, costs, storage, demand forecasting, and information flow. Suggestions are provided for both systems to improve operations.