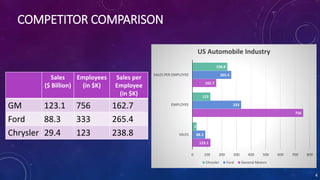

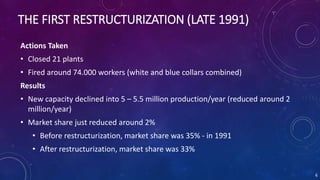

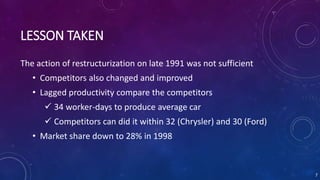

General Motors faced huge losses in the early 1990s due to inefficient operations and a bloated workforce. Their first restructuring in 1991 closed plants and laid off workers but did not go far enough, as competitors improved and GM's market share continued to drop. A second restructuring in the mid-1990s consolidated operations, reduced models, implemented lean manufacturing techniques like just-in-time inventory, and outsourced more assembly tasks. This made GM more efficient and profitable, allowing them to surpass Ford by 2002 through improved productivity, quality, and profitability.