The document summarizes experiments using a Gas Module attached to an H-Cube Pro reactor to enable gas-liquid and gas-solid reactions. Key findings include:

1) The Gas Module allows versatile use of various gases including oxygen, carbon monoxide, ethylene and others for reactions.

2) Reactions with gases are fast, completing in under 10 minutes, and the Gas Module is capable of pressures up to 100 bar.

3) Optimization of alcohol oxidation over different catalysts and conditions showed the highest conversion and selectivity at 100°C, 100 bar, and 5% Ru/Al2O3 catalyst.

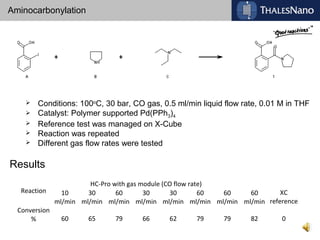

4) Aminocarbonylation reactions achieved up to 82% conversion using different