This document discusses flow chemistry and its advantages over traditional batch chemistry. Flow chemistry involves performing reactions continuously in a small-scale reactor rather than in batches. It allows for better temperature control, safer handling of hazardous reagents like gases or exothermic reactions, higher selectivity and productivity, and easier scale-up. Areas that benefit greatly from flow chemistry include exothermic reactions, reactions with gases, and scale-up. Miniaturized microreactors in flow systems provide enhanced heat and mass transfer for improved reaction control and safety. Overall, flow chemistry is a useful method for performing chemistry in a safer, more efficient, and reproducible manner compared to batch.

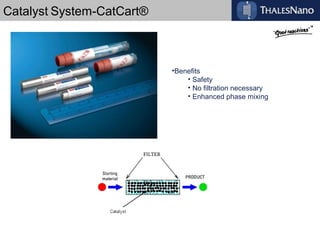

![Carbonylation leading to esters

O

Fibrecat 1001:

Pd content [mmol/g]: 0.47,

Load: mmol/catcart: 0.114.

Void volume: 0.62 ml

O

I

CO, DBU

Fibercat 1001

EtOH

O

Ethanolic solution: DBU: 1.1 eq., 4iodo-anisole: 1.0 ekv,

concentration: 0.1 M - 1.0 M

O

Concentration

Liquid

Temperature Gas flow Pressure Pressure Conversion Selectivity

flow rate

(oC)

rate

(bar)

drop

(%)

(%)

(mL/min)

(ml/min)

(bar)

0.1 M

0.1 M

0.1 M

1M

1M

0.5

0.5

0.5

0.5

1

150

150

150

150

150

10

10

50

100

100

10

30

10

30

30

2

3

3

2

2

>99

>99

>99

>99

98.3

>99

>99

>99

>99

>99

Microwave reference from Nicholas Leadbeater’s lab (Org.Biomol.Chem. 2007, 65):

Concentration: 0.1M, Pressure: 10 bar, Temperature: 125oC, Reaction time: 30 min

Conversion: 90%

Flow reference from Nicholas Leadbeater’s lab (Org.Biomol.Chem. 2011, 6575):

Concentration: 1M, Pressure: 17 bar, Temperature: 120oC Residence time: 120 min

Conversion: 98%](https://image.slidesharecdn.com/thalesnanopresentationfrost2013-131030082859-phpapp01/85/ThalesNano-Presentation-2013-19-320.jpg)

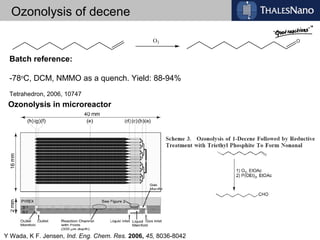

![Swern Oxidation

If the temperature is not kept near -78°C, mixed thioacetals may result:

Cryogenic operating conditions

(< - 60°C), limit its utility for scale up

operations in batch.

Residence

time (tR1) [s]

2.4

Microreactor

0.01

0.01

Method

Flask

Chemistry-A European Journal 2008, 7450

T [oC]

-20

0

20

-20

-70

Selectivity of

cyclohexanone [%]

88

89

88

19

83](https://image.slidesharecdn.com/thalesnanopresentationfrost2013-131030082859-phpapp01/85/ThalesNano-Presentation-2013-43-320.jpg)