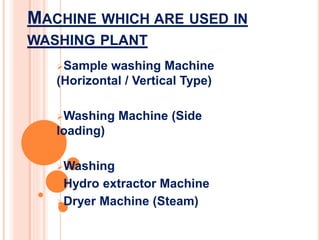

The document discusses garment washing, a technology that modifies the appearance, comfort, and fashion of garments through various washing techniques. It outlines the objectives, advantages, and types of garment washing processes, including dry and wet methods, as well as the machines and chemicals used in the washing plants. Additionally, it details different types of garment washing machines and their features.