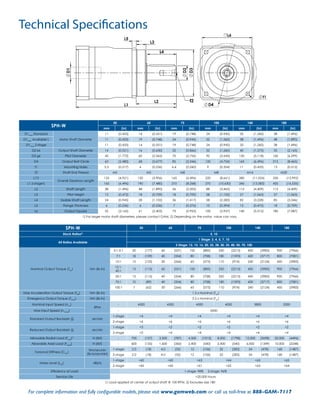

The SPH series from GAM features helical gears that provide higher torque and precision over other gear reducers. The SPH was designed with special attention to every aspect to deliver powerful and efficient performance for demanding servo applications. It uses helical gears, optimized bearings, and a rigid housing to smoothly and quietly deliver torque while accommodating high loads. The SPH comes in different configurations and customizable options to flexibly meet application needs.