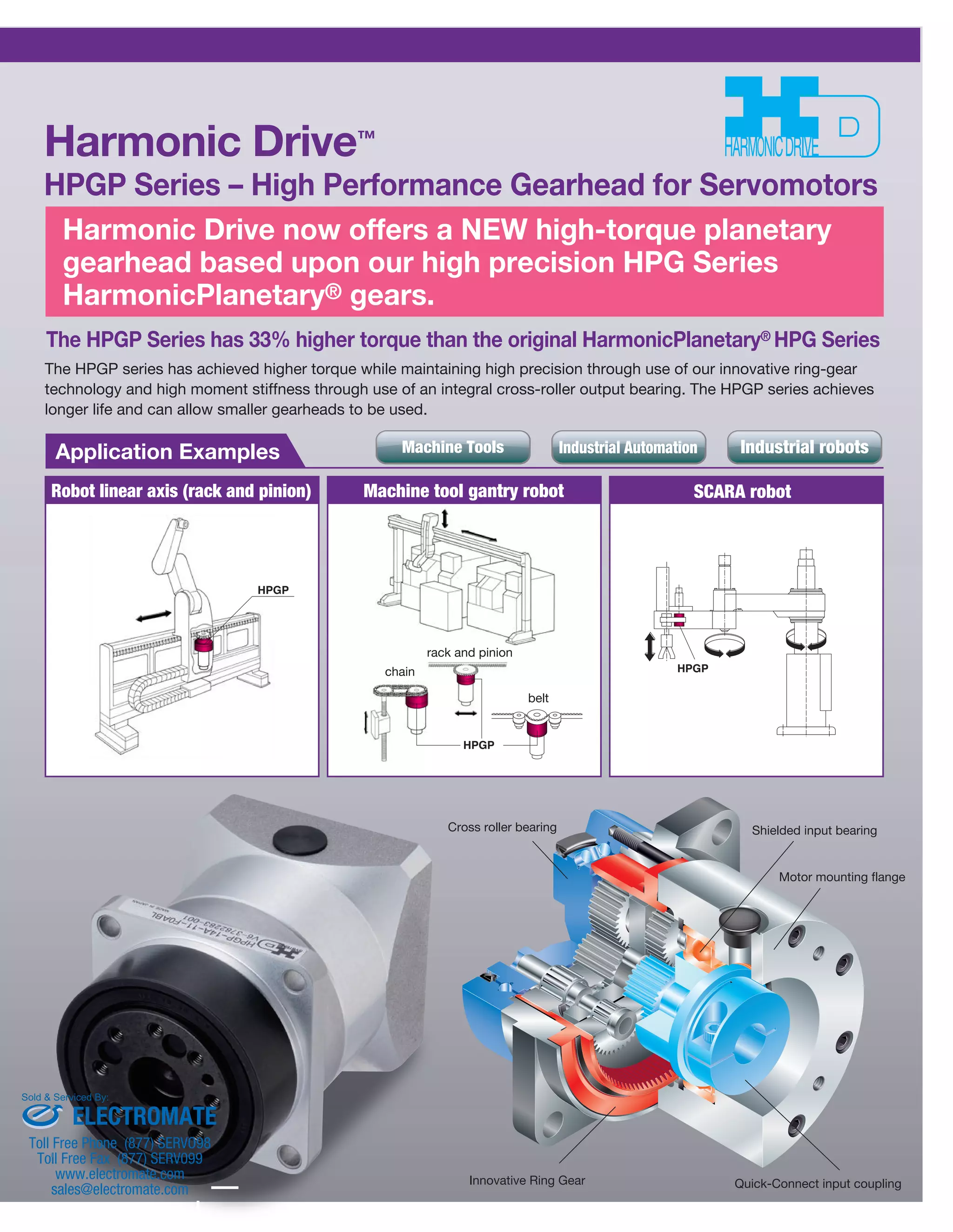

The HPGP Series is a new high-torque planetary gearhead from Harmonic Drive with 33% higher torque than the original HPG Series. It achieves higher torque through innovative ring-gear technology and a high moment stiffness cross-roller output bearing, allowing for longer life and use of smaller gearheads.