The document discusses the GAM PE series of gearboxes. It provides details on their specifications including sizes, ratios, torque capabilities, speeds, backlash, loads, and other technical specifications. The PE series offers a reliable and cost-effective alternative for motion control applications requiring minimal radial or axial loads. It is available in metric and NEMA sizes with a wide range of ratios and customizations possible.

![46

t1

L7

L8

D4

L5

L4

PE-W

D5

D3h7

f1

L2

L3

D2k6

f2 L6

L1

D1

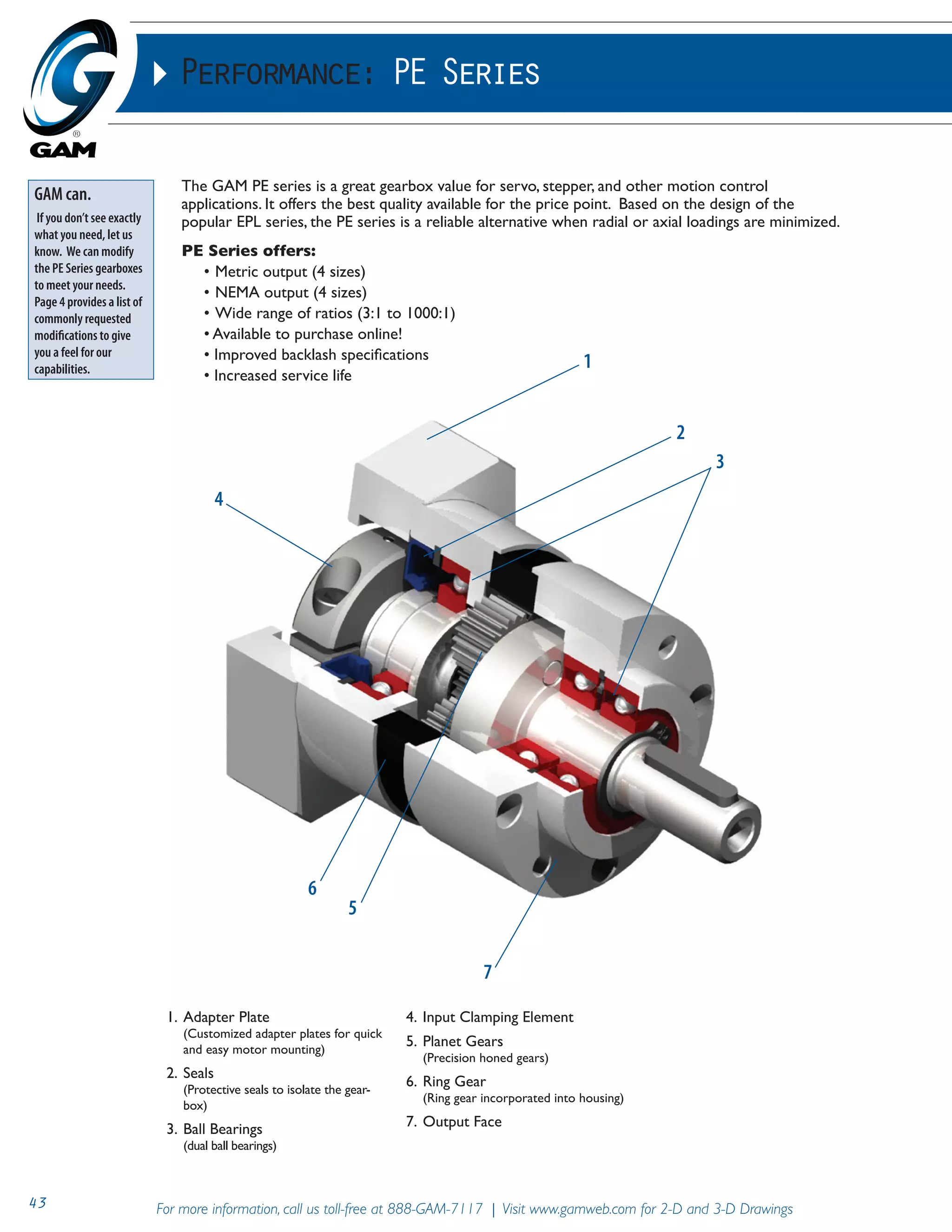

mm (in) 50 64 84 118

D1 max standard* motor shaft diameter 11 (0.433) 14 (0.551) 19 (0.748) 24 (0.945)

D1 max available* motor shaft diameter 14 (0.551) 16 (0.630) 24 (0.945) 32 (1.260)

D2 k6 output shaft diameter 12 (0.472) 14 (0.551) 20 (0.787) 25 (0.984)

D3 h7 pilot diameter 35 (1.378) 40 (1.575) 55 (2.165) 80 (3.15)

D4 bolt circle 44 (1.732) 52 (2.047) 70 (2.756) 100 (3.937)

D5 housing diameter 50 (1.969) 64 (2.52) 84 (3.307) 118 (4.646)

f1 shaft thread M4x8 M5x12 M6x16 M10x22

f2 mounting holes M4x6 M5x12 M6x14 M8x18

L1 1-STAGE**

gearbox total length

93 (3.661) 117 (4.606) 162 (6.378) 199 (7.835)

L1 2-STAGE** 108 (4.252) 139 (5.472) 195 (7.677) 239 (9.409)

L1 3-STAGE** - (-) 161 (6.339) 228 (8.976) 280 (11.024)

L2 shaft length 24.5 (0.965) 39 (1.535) 54 (2.126) 61 (2.402)

L3 key length 16 (0.63) 25 (0.984) 36 (1.417) 45 (1.772)

L4 usable shaft length 18 (0.709) 30 (1.181) 45 (1.772) 50 (1.969)

L5 pilot height 4 (0.157) 8 (0.315) 8 (0.315) 10 (0.394)

L6 key width 4 (0.157) 5 (0.197) 6 (0.236) 8 (0.315)

L7 key height 13.5 (0.531) 16 (0.63) 22.5 (0.886) 28 (1.102)

L8** adapter size 50 (1.969) 70 (2.756) 90 (3.543) 120 (4.724)

t1*** allowable shaft length 23 (0.87) 23 (0.906) 30 (1.181) 40 (1.575)

* for larger motor shaft diameters, please contact GAM ** depending on the motor, value can vary *** long motor shafts can be accommodated, but overall gearbox length will grow

****The PE-W-050 may have a blue ring gear

Recommended Output Coupling (if necessary)

metal bellows

KLC-25 KLC-50 KLC-125 KM-270

elastomer

EKC-25 EKC-35 EKC-80 or 110 EKM-300

Tolerances (mm)

Size k6 h7

Over 6 +0.010 0

Thru 10 +0.001 -0.015

Over 10 +0.012 0

Thru 18 +0.001 -0.018

Over 18 +0.015 0

Thru 30 +0.002 -0.021

Over 30 +0.018 0

Thru 50 +0.002 -0.025

Over 50 +0.021 0

Thru 80 +0.002 -0.030

TYPE CODES FOR PE-W SERIES (METRIC)

Example: PE - W - 084 - 005 G - [115 - A01] - S111

Gearbox Series

PE w/ Metric Output

Special Options

Assigned by GAM

Motor Mount Kit

Assigned by GAM

Gearbox Style

W = Output Shaft

Gearbox Size

050, 064, 084, 118

Ratio

3, 4, 5, 7, 10, 12, 16, 20, 25, 35, 40, 50, 70, 100,

120, 160, 200, 250, 350, 490, 700, 000=1000

Options Available for This Product

G = Key on output shaft per DIN6885](https://image.slidesharecdn.com/gampebrochure-141001201225-phpapp02/85/Gam-pe-brochure-4-320.jpg)

![48

t1

L6

ØD4

PE-N

L3

D3 h7

D2 k6

L7

D5

L2

L4

D1

L5

L1 L8

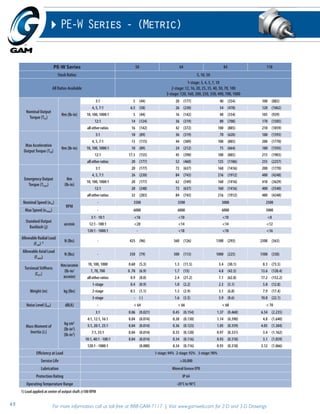

PE-N Series

17 23 34 42

mm (in) mm (in) mm (in) mm (in)

D1 max standard* motor shaft diameter 11 (0.433) 11 (0.433) 14 (0.551) 19 (0.748)

D1 max available* motor shaft diameter 11 (0.433) 14 (0.551) 16 (0.630) 24 (0.945)

D2 k6 output shaft diameter 9.525 (0.375) 9.525 (0.375) 12.700 (0.500) 19.05 (0.750)

D3 h7 pilot diameter 21.97 (0.865) 38.100 (1.500) 73.025 (2.875) 55.55 (2.187)

D4 bolt circle 43.8 (1.725) 66.7 (2.625) 98.400 (3.875) 125.7 (4.95)

D5 mounting holes 3.25 (0.128) 5 (0.2) 5.5 (0.22) 7.1 (0.28)

L1 1-STAGE**

gearbox total length

108 (4.252) 102 (4.016) 125 (4.921) 162 (6.378)

L1 2-STAGE** 124 (4.882) 122.5 (4.823) 147 (5.787) 194.5 (7.657)

L1 3-STAGE** - (-) - (-) 169 (6.654) 227 (8.937)

L2 shaft length 25.4 (1.00) 25.4 (1.00) 31.8 (1.25) 31.8 (1.25)

L3 key length - (-) - (-) 27 (1.06) 29 (1.14)

L4 pilot height 1.6 (0.063) 1.6 (0.06) 1.7 (0.07) 2.4 (0.09)

L5 fl ange thickness 4.9 (0.193) 5 (0.2) 10 (0.39) 13 (0.51)

L6 key width - (-) - (-) 3.2 (0.13) 4.8 (0.19)

L7 key height / fl at height 9.14 (0.36) 9.14 (0.36) 14.3 (0.56) 18.260 (0.72)

L8 output fl ange size 40 (1.575) 57.14 (2.25) 82.55 (3.25) 106.68 (4.20)

t1*** allowable motor shaft 25 (0.984) 23 (0.87) 32 (1.26) 40 (1.575)

* for larger motor shaft diameters, please contact GAM **depending on the motor, value can vary *** longer motor shafts can be accommodated, but overall gearbox length will grow

Recommended Output Coupling (if necessary)

metal bellows

KLC-25 KLC-25 KLC-50 KLC-125

elastomer

EKC-25 EKC-25 EKC-80 EKC-110

Tolerances (mm)

Size k6 h7

Over 6 +0.010 0

Thru 10 +0.001 -0.015

Over 10 +0.012 0

Thru 18 +0.001 -0.018

Over 18 +0.015 0

Thru 30 +0.002 -0.021

Over 30 +0.018 0

Thru 50 +0.002 -0.025

Over 50 +0.021 0

Thru 80 +0.002 -0.030

TYPE CODES FOR PE-N SERIES (NEMA)

Example: PE - N23 - 005 G - [115 - A01] - S111

Gearbox Series

NPE w/ NEMA output

Special Options

Assigned by GAM

Motor Mount Kit

Assigned by GAM

Gearbox Style

N17 = NEMA17

N23 = NEMA23

N34 = NEMA34

N42 = NEMA42

Ratio

3, 4, 5, 7, 10, 12, 16, 20, 25, 35, 40, 50, 70, 100,

120, 160, 200, 250, 350, 490, 700, 000=1000

Options Available for This Product

G = Key on output shaft per DIN6885

fl at on NEMA 17 and NEMA 23](https://image.slidesharecdn.com/gampebrochure-141001201225-phpapp02/85/Gam-pe-brochure-6-320.jpg)