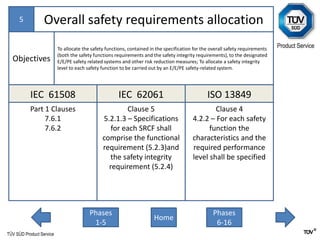

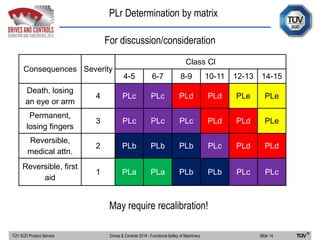

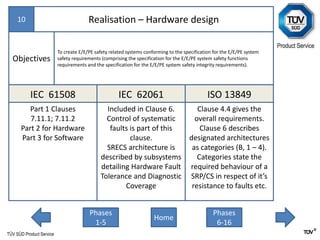

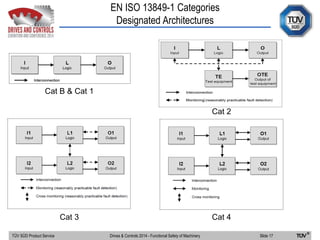

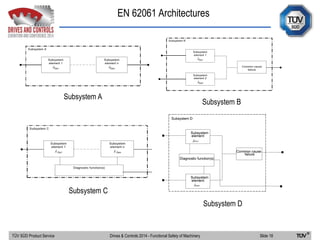

The document discusses current functional safety standards for machinery, specifically ISO 13849-1 and IEC 62061, which have been in place since 2007 and share similar basic requirements but differ in details. It highlights the intention to merge these standards into a single ISO/IEC standard (ISO/IEC 17305) and outlines techniques for compliance with both standards while preparing for this consolidation. The presentation emphasizes the importance of feedback on practical applications of these standards to aid in future developments.

![PL and SIL

TÜV SÜD Product Service Slide 15Drives & Controls 2014 - Functional Safety of Machinery

EN ISO 13849-1

Performance Level

(PL)

Average

probability of a

dangerous failure

per hour [1/h]

EN 62061

Safety Integrity

Level (SIL)

a ≥ 10-5 to < 10-4 no special safety

requirements

b ≥ 3 x 10-6 to < 10-5 1

c ≥ 10-6 to < 3 x 10-6 1

d ≥ 10-7 to < 10-6 2

e ≥ 10-8 to < 10-7 3](https://image.slidesharecdn.com/functionalsafetystandardsformachinery-160802124903/85/Functional-safety-standards_for_machinery-15-320.jpg)

![PFH Verification

TÜV SÜD Product Service Slide 21Drives & Controls 2014 - Functional Safety of Machinery

DeDeDeDssD TDCTDC })]1([

2

]2{[)1( 1

222 2

hPFH DD 1

8760

1

d

D

MTTF

PFHCategory 1

Or

Subsystem A

Subsystem D](https://image.slidesharecdn.com/functionalsafetystandardsformachinery-160802124903/85/Functional-safety-standards_for_machinery-21-320.jpg)