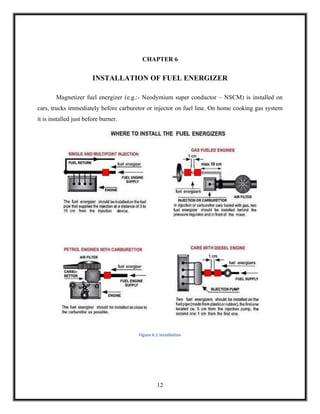

The document is a seminar report on a fuel energizer device. It discusses how the device works by subjecting fuel to a magnetic field before combustion. This realigns fuel molecules to burn more completely, improving fuel efficiency up to 28% and reducing emissions. The report covers the need for such a device, its working principle, installation, comparison to catalytic converters, and applications. In summary, the fuel energizer improves fuel efficiency and reduces emissions by realigning fuel molecules through magnetism prior to combustion.

![CHAPTER 7

COMPARISION WITH CATALYTIC CONVERTOR

CATALYTIC CONVERTOR-

Catalytic converter is a device which used to convert toxic exhaust emission from an IC

engine into non toxic substance

Inside a cc. a catalyst stimulate a chemical reaction in which noxious byproduct of

combustion undergoes a chemical reaction

Many vehicles have a close-coupled catalysts located near the engine's exhaust manifold.

This unit heats up quickly due to its proximity to the engine, and reduces cold-engine emissions

by burning off hydrocarbons from the extra-rich mixture used to start a cold engine.

In the past, some three-way catalytic converter systems used an air-injection tube between

the first (NOx reduction) and second (HC and CO oxidation) stages of the converter. This tube

was part of a secondary air injection system. The injected air provided oxygen for the oxidation

reactions. An upstream air injection point was also sometimes present to provide oxygen during

engine warmup, which caused unburned fuel to ignite in the exhaust tract before reaching the

catalytic converter. This cleaned up the exhaust and reduced the engine runtime needed for the

catalytic converter to reach its "light-off" or operating temperature.

Most modern catalytic converter systems do not have air injection systems] Instead, they

provide a constantly varying air-fuel mixture that quickly and continually cycles between lean

and rich exhaust. Oxygen sensors are used to monitor the exhaust oxygen content before and

after the catalytic converter and this information is used by the Electronic control unit to adjust

the fuel injection so as to prevent the first (NOx reduction) catalyst from becoming oxygen-

loaded while ensuring the second (HC and CO oxidization) catalyst is sufficiently oxygen-

saturated. The reduction and oxidation catalysts are typically contained in a common housing,

however in some instances they may be housed separately

13](https://image.slidesharecdn.com/sumit123-111001125646-phpapp02/85/FUEL-ENERGIZER-13-320.jpg)