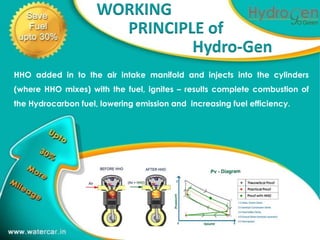

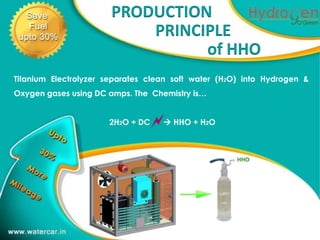

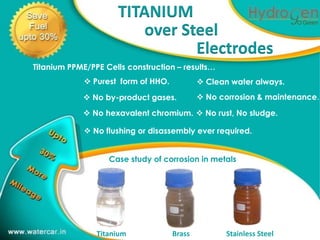

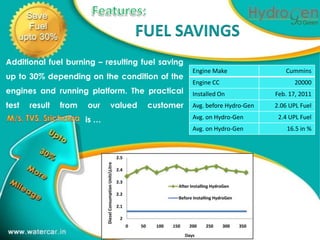

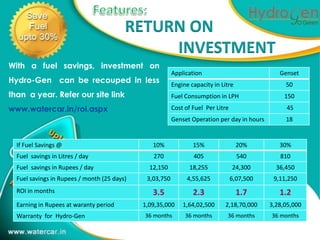

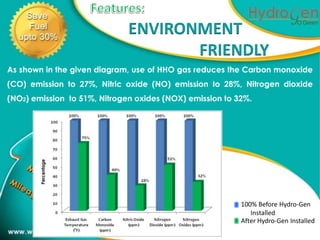

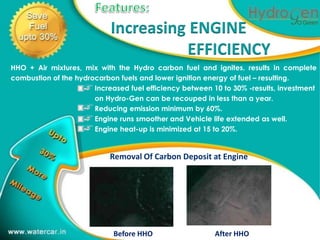

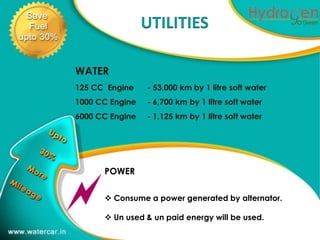

The document details the benefits and workings of HHO (oxy-hydrogen) gas as a fuel supplement for various engines, highlighting improvements in fuel efficiency by 10-30% and significant reductions in harmful emissions. HHO is generated through a titanium electrolyzer using clean water, ensuring no harmful by-products or maintenance issues, and can be integrated easily into existing engines. The text also includes case studies and potential savings, suggesting a quick return on investment for users adopting this technology.