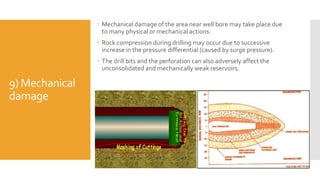

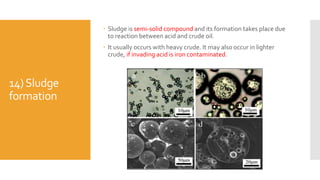

This document discusses various types of formation damage that can occur including plugging by solid particles, plugging by formation solids, clay swelling, dispersion of clayey platelets, water block, emulsion formation, precipitation of inorganic scales, precipitation related to acidizing, mechanical damage, paraffin deposition, precipitation of asphaltene, wettability alteration, reduced relative permeability, sludge formation, damage by bacteria, polymer invasion, and gas breakout. Formation damage refers to any process that reduces permeability in the formation near the wellbore and decreases productivity over time. Common causes include invasion of foreign solids or fluids, changes in wettability, mineral precipitation, and bacterial growth. Proper design of completion and stimulation methods

![15) Damage by

bacteria

Bacteria can be a serious problem in production operations

because of what they consume and their byproducts.

Bacteria can grow in many different environments and conditions:

-temperatures ranging from 12°F to greater than 250°F [–11° to

>120°C],

-pH values ranging from 1 to 11,

-salinities to 30% and

-pressures to 25,000 psi

The most troublesome bacteria in the oilfield are sulfate-reducing

bacteria, slime formers, iron oxidizing bacteria and bacteria that

attack polymers in fracturing fluids.](https://image.slidesharecdn.com/formationdamage-190913141109/85/Formation-damage-16-320.jpg)