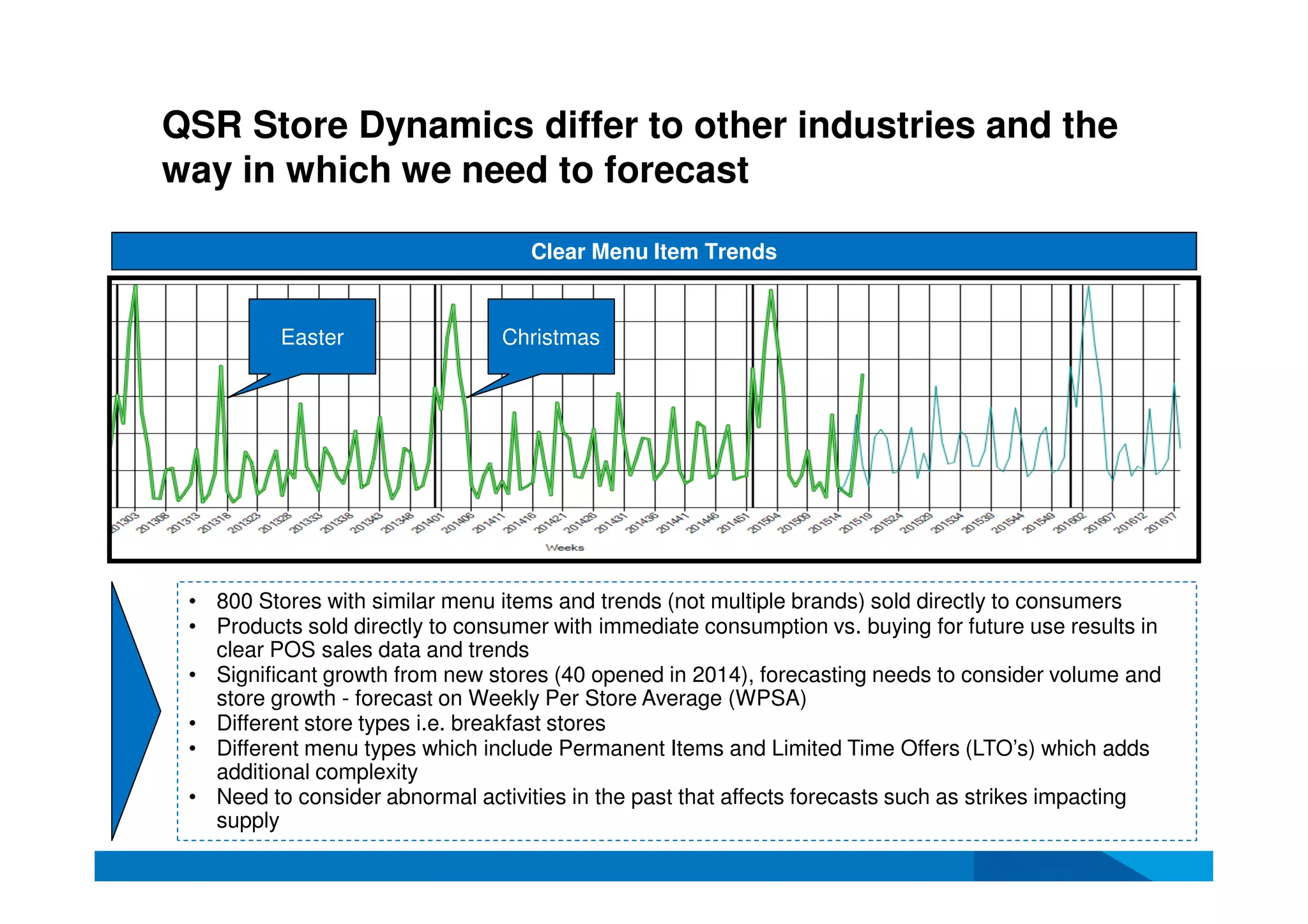

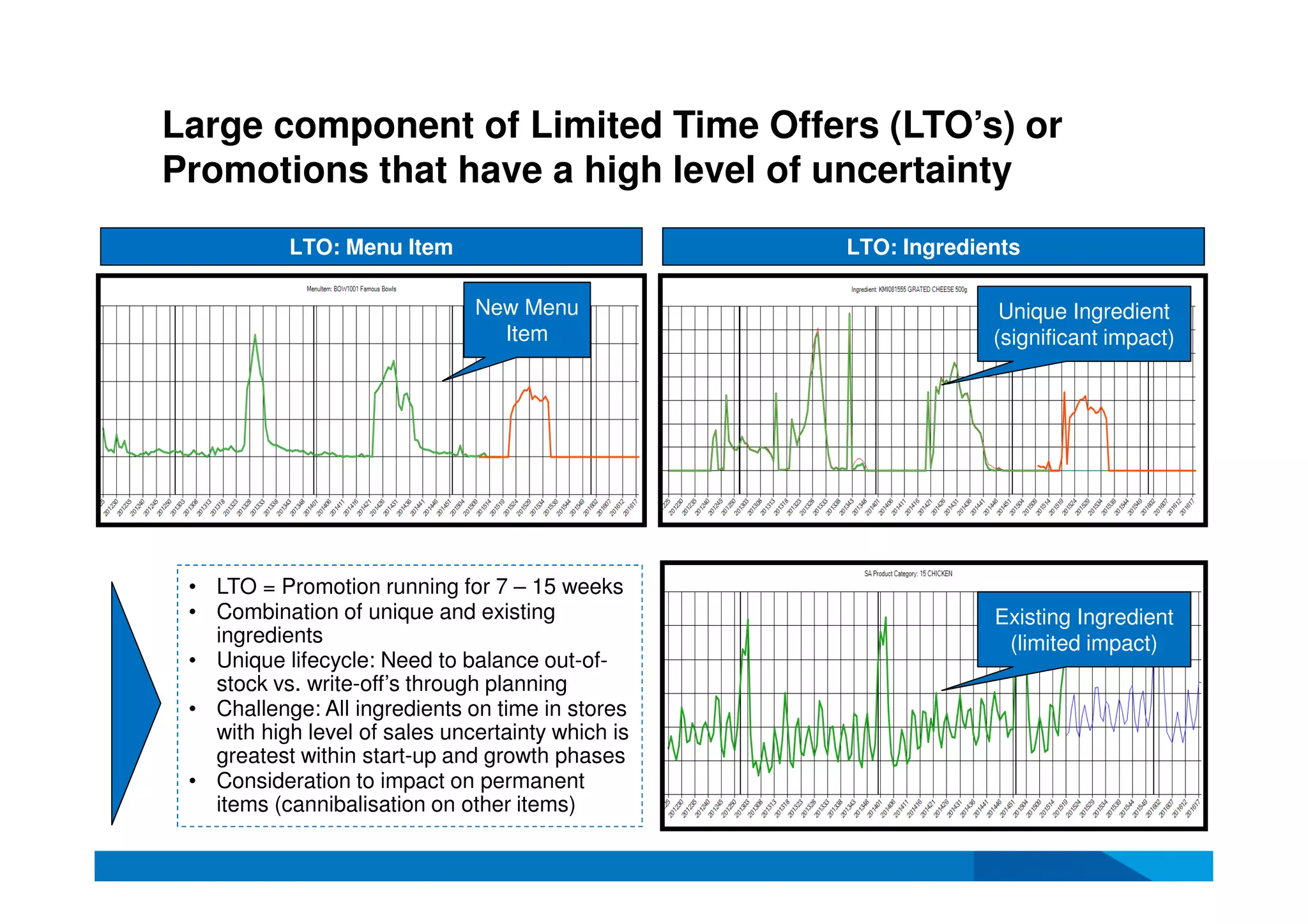

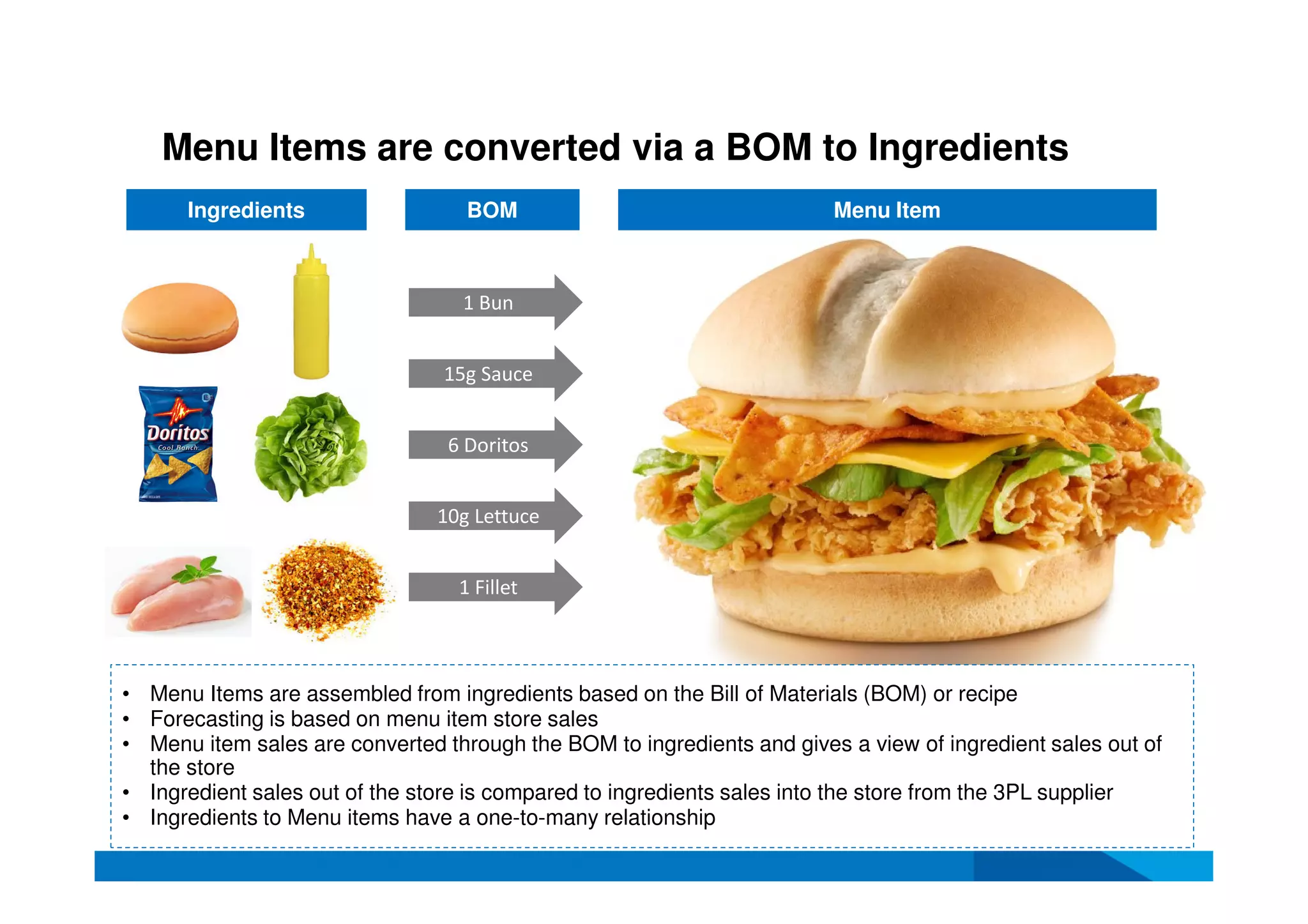

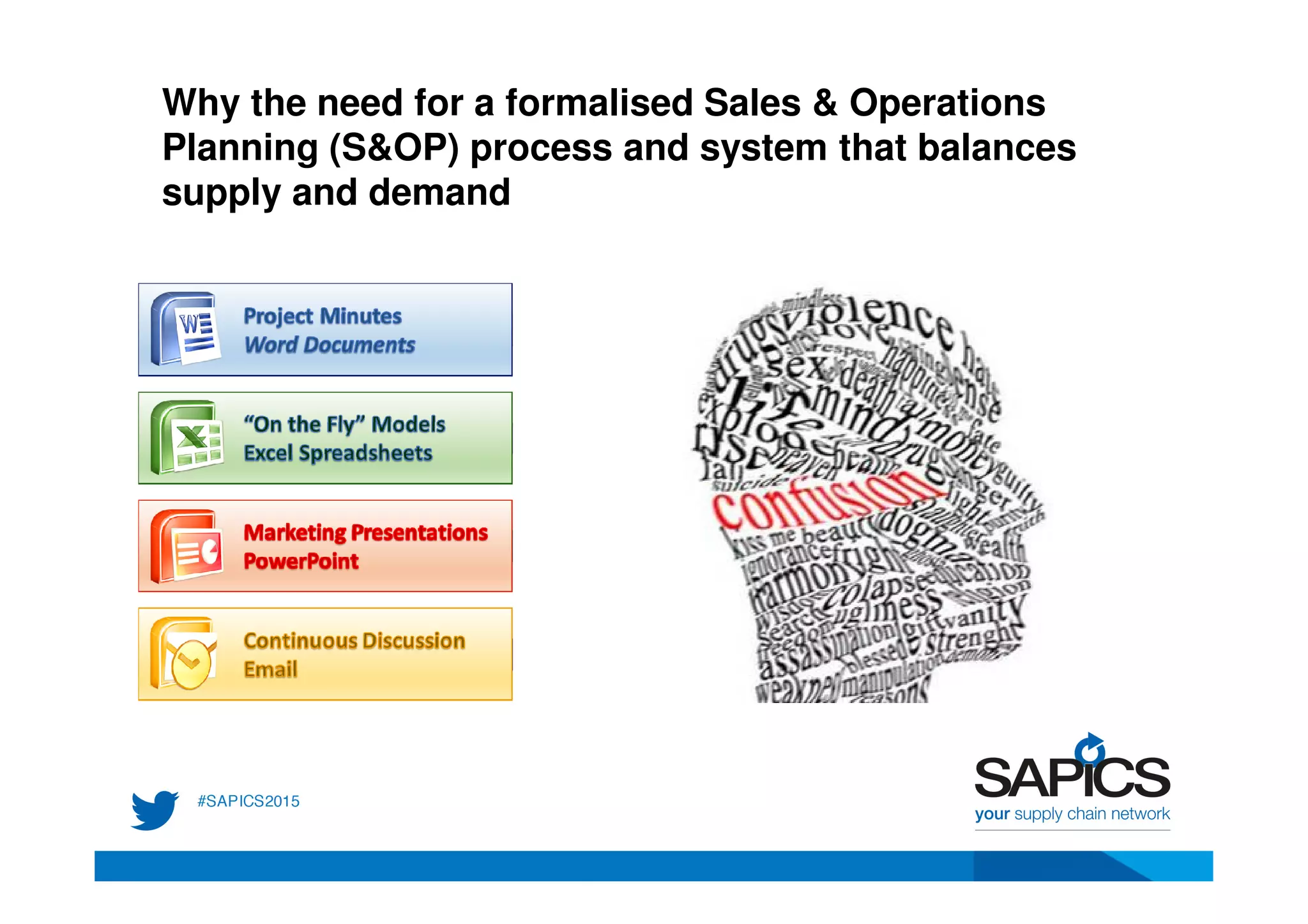

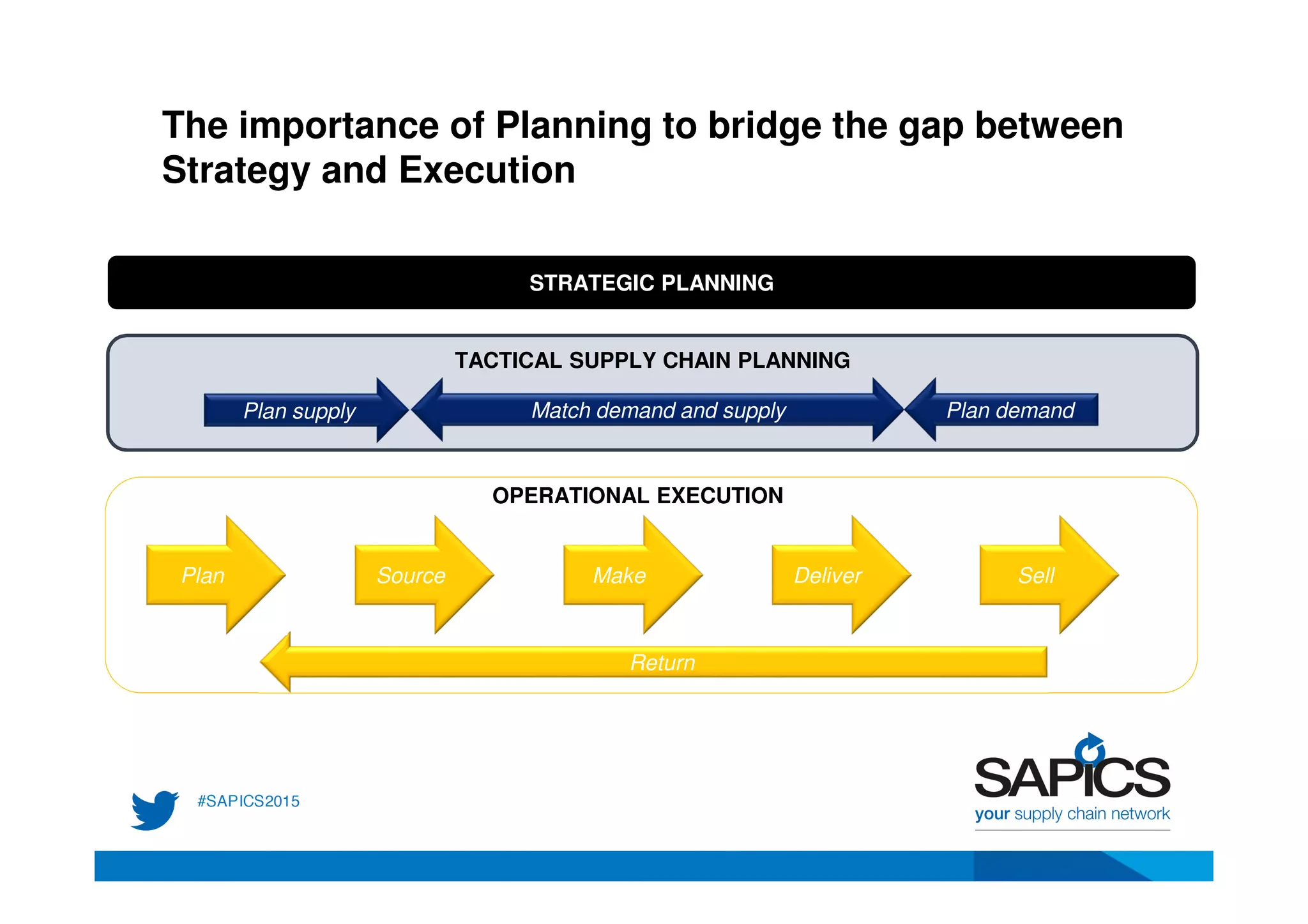

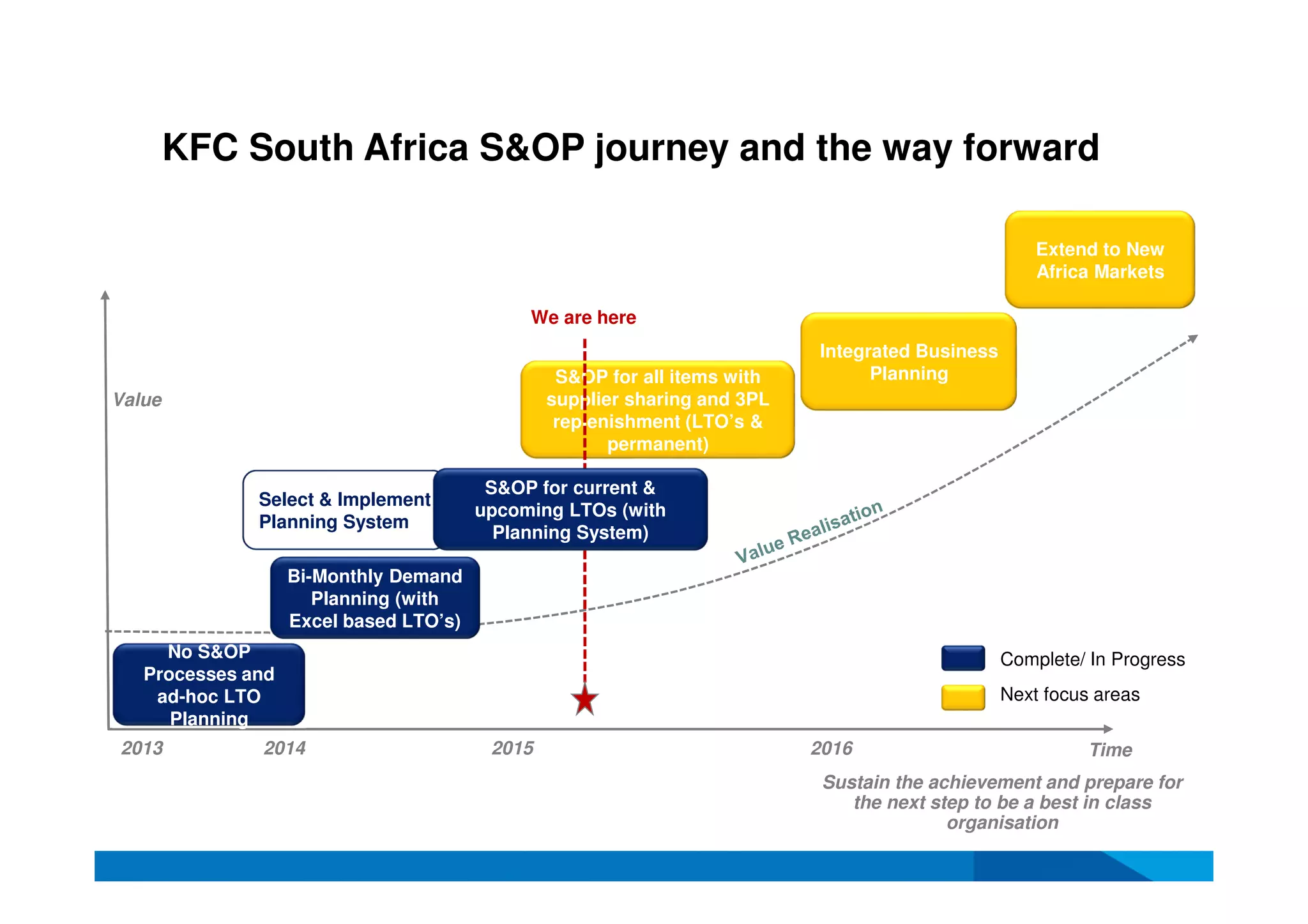

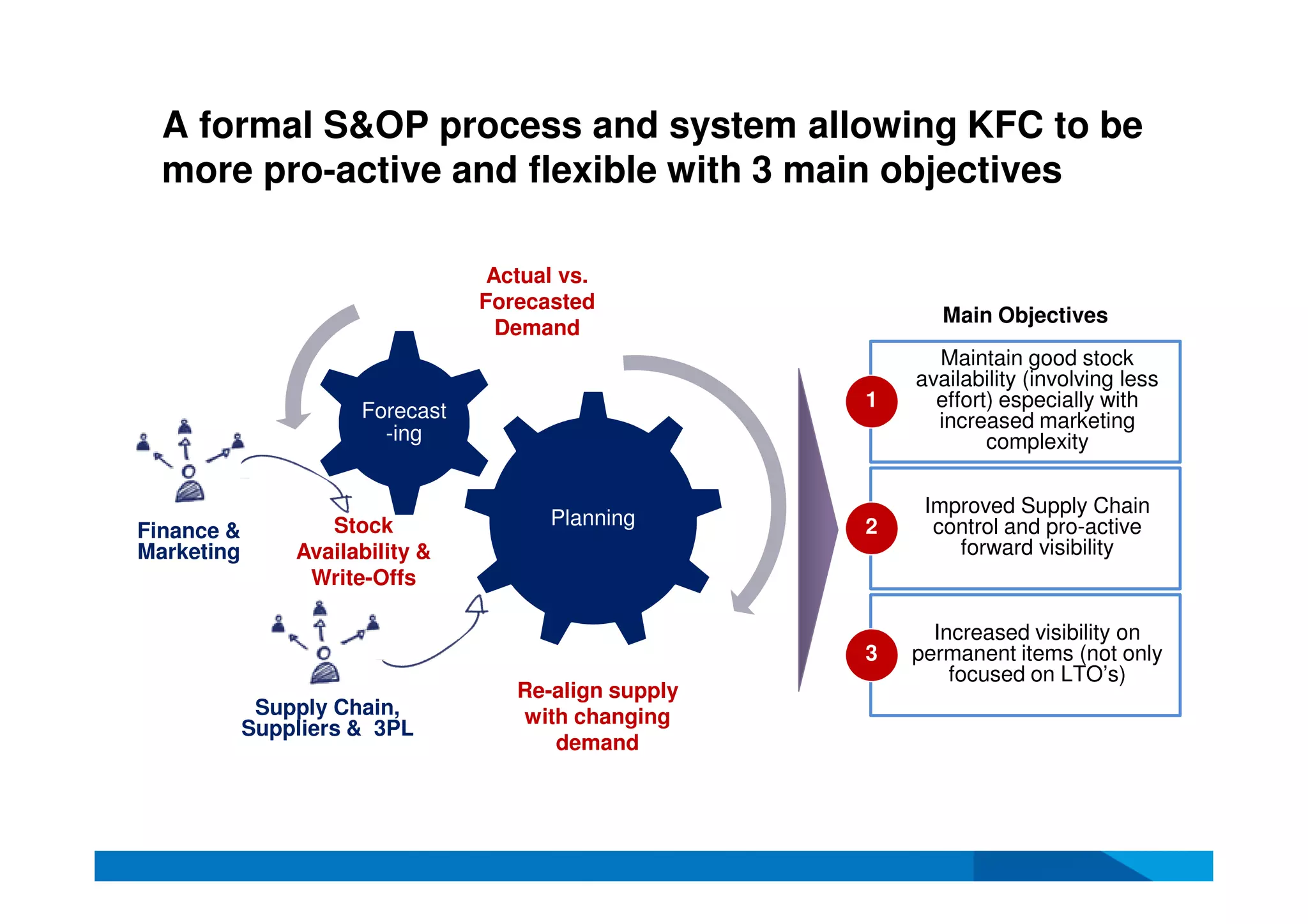

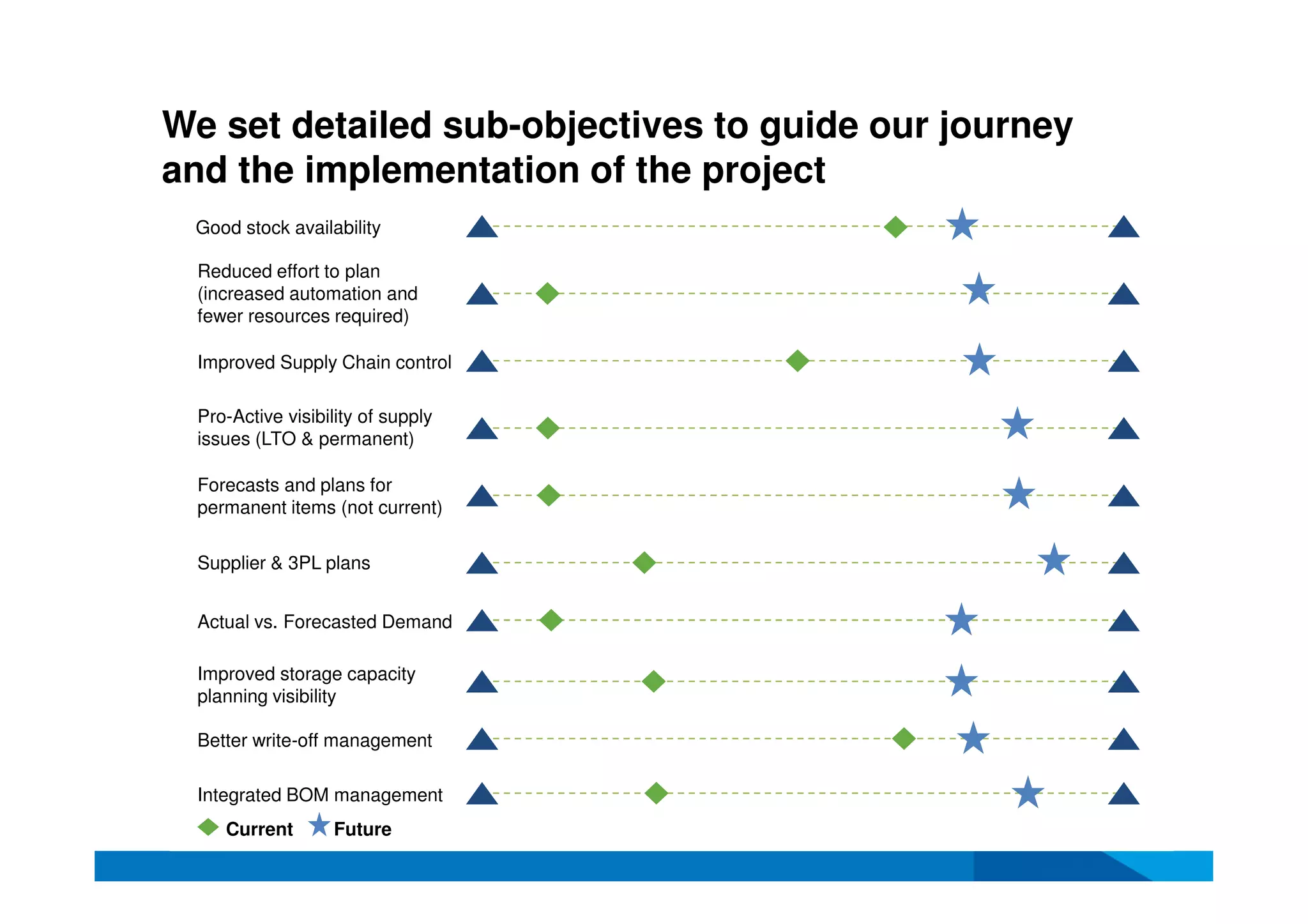

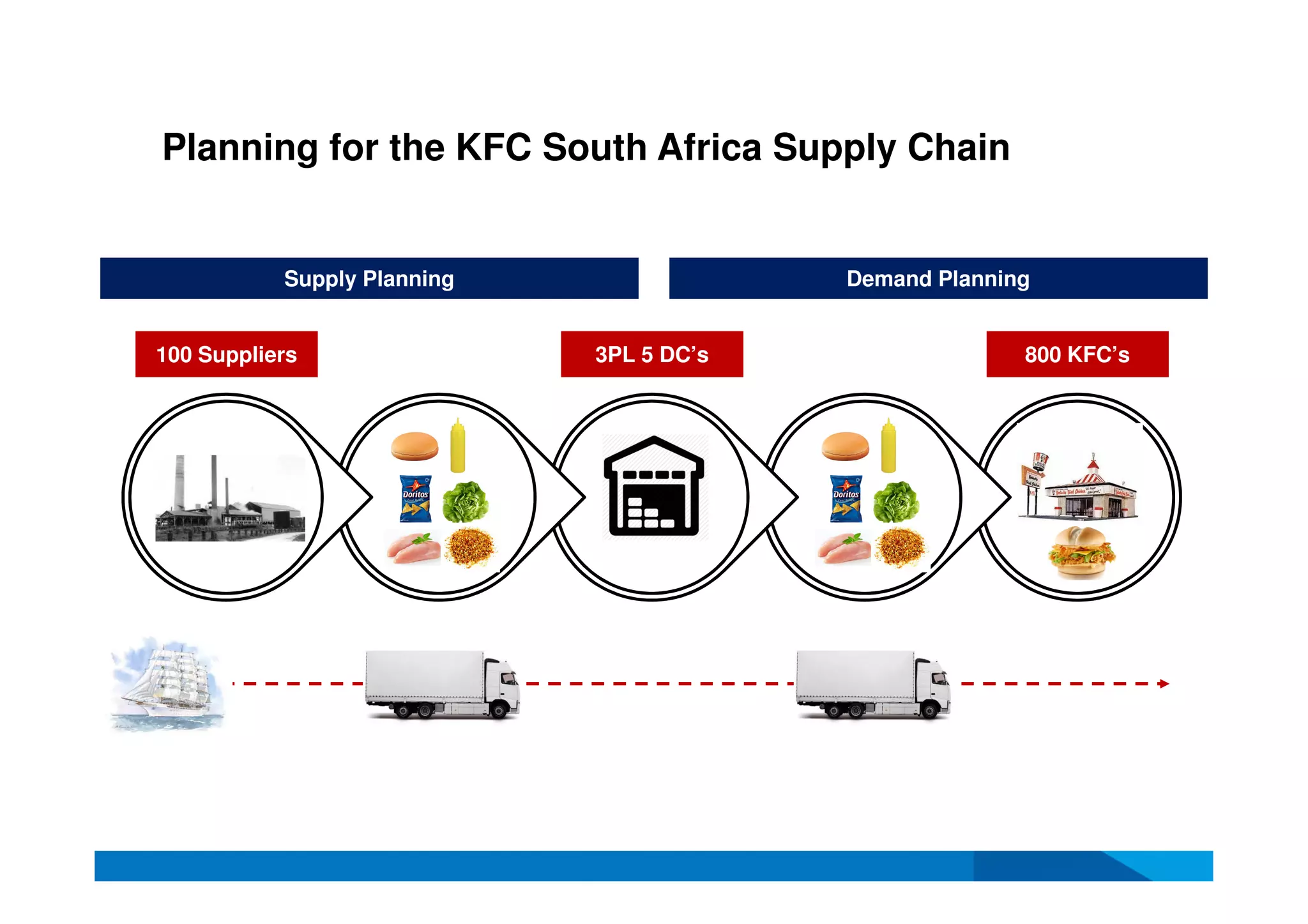

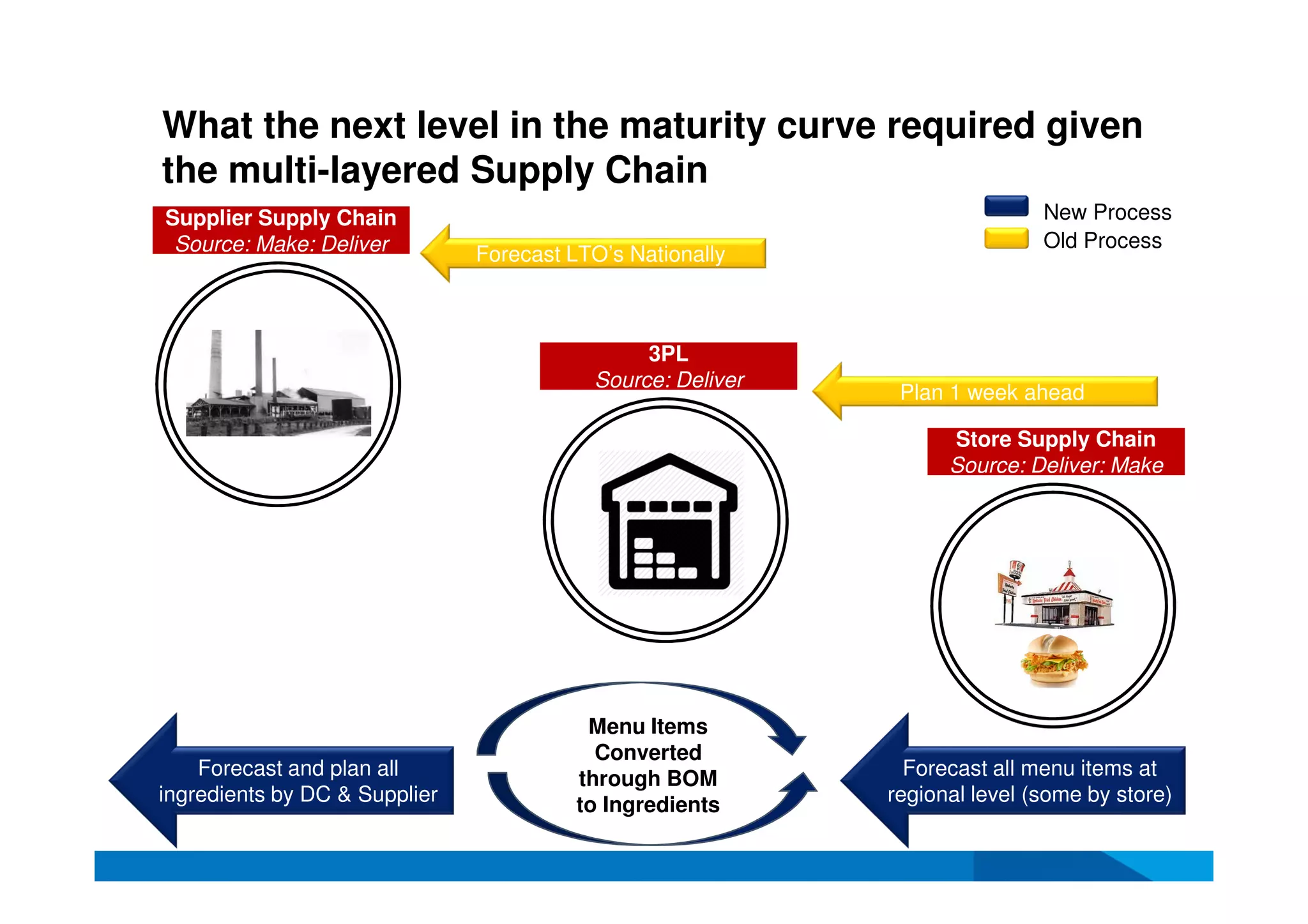

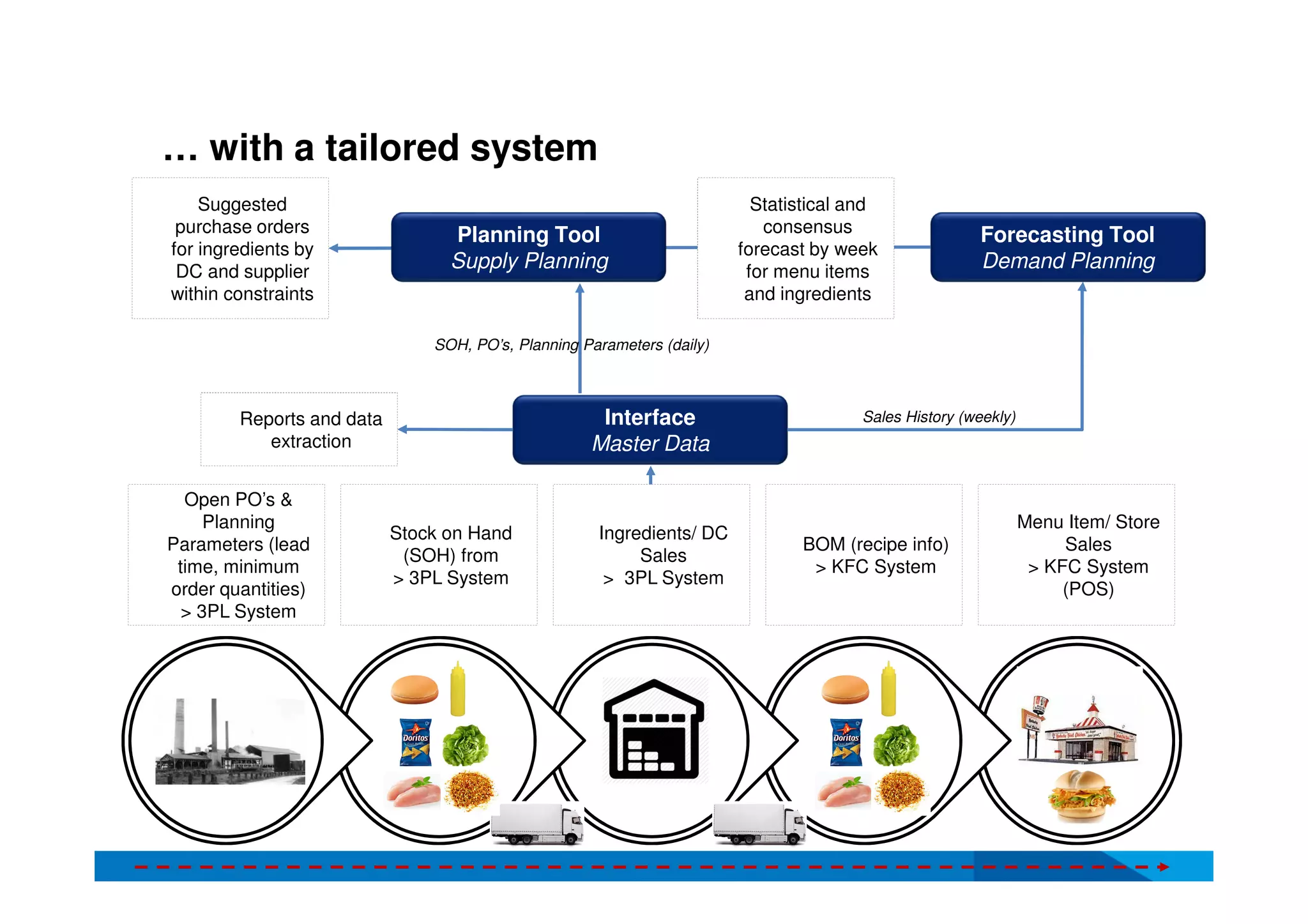

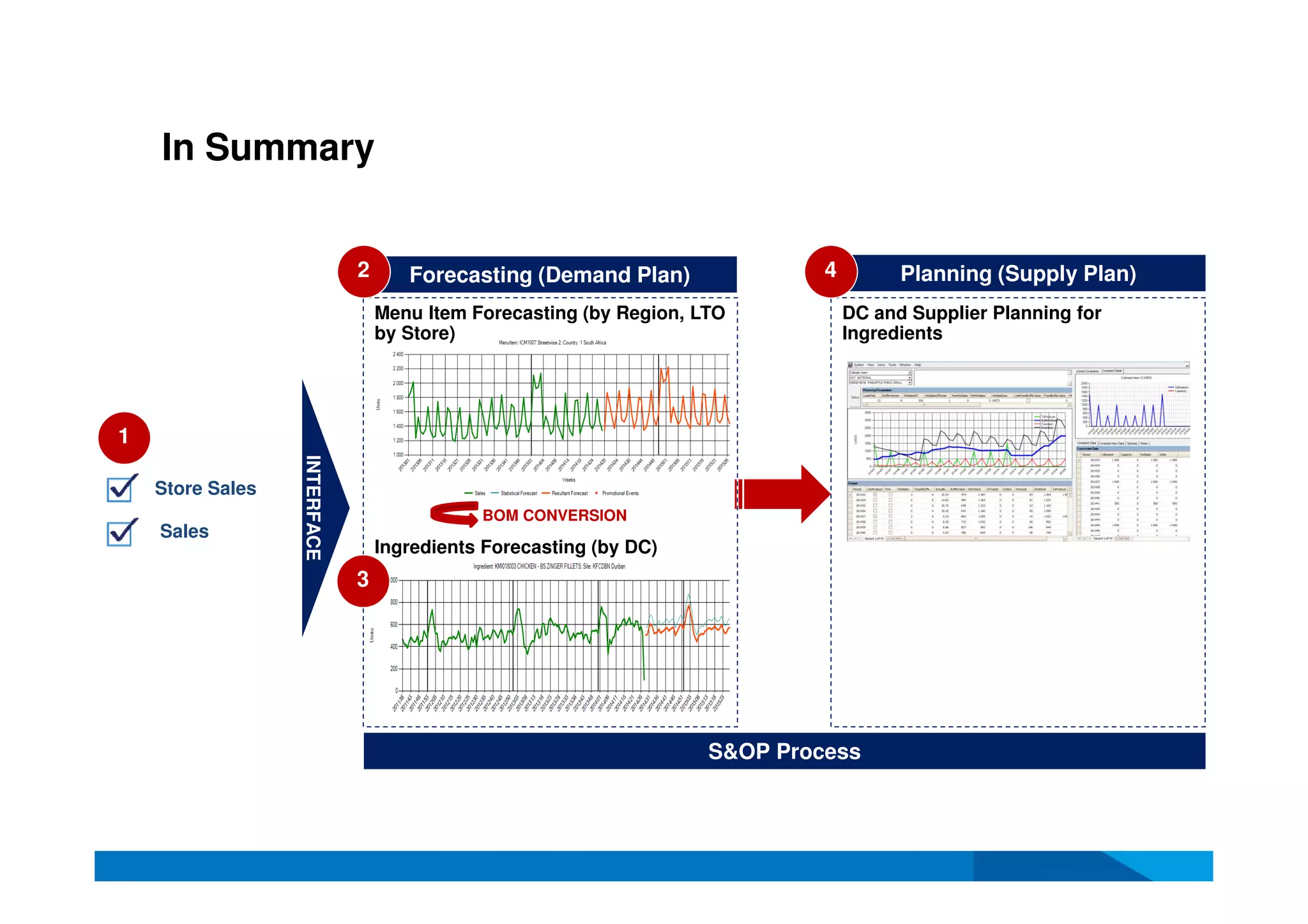

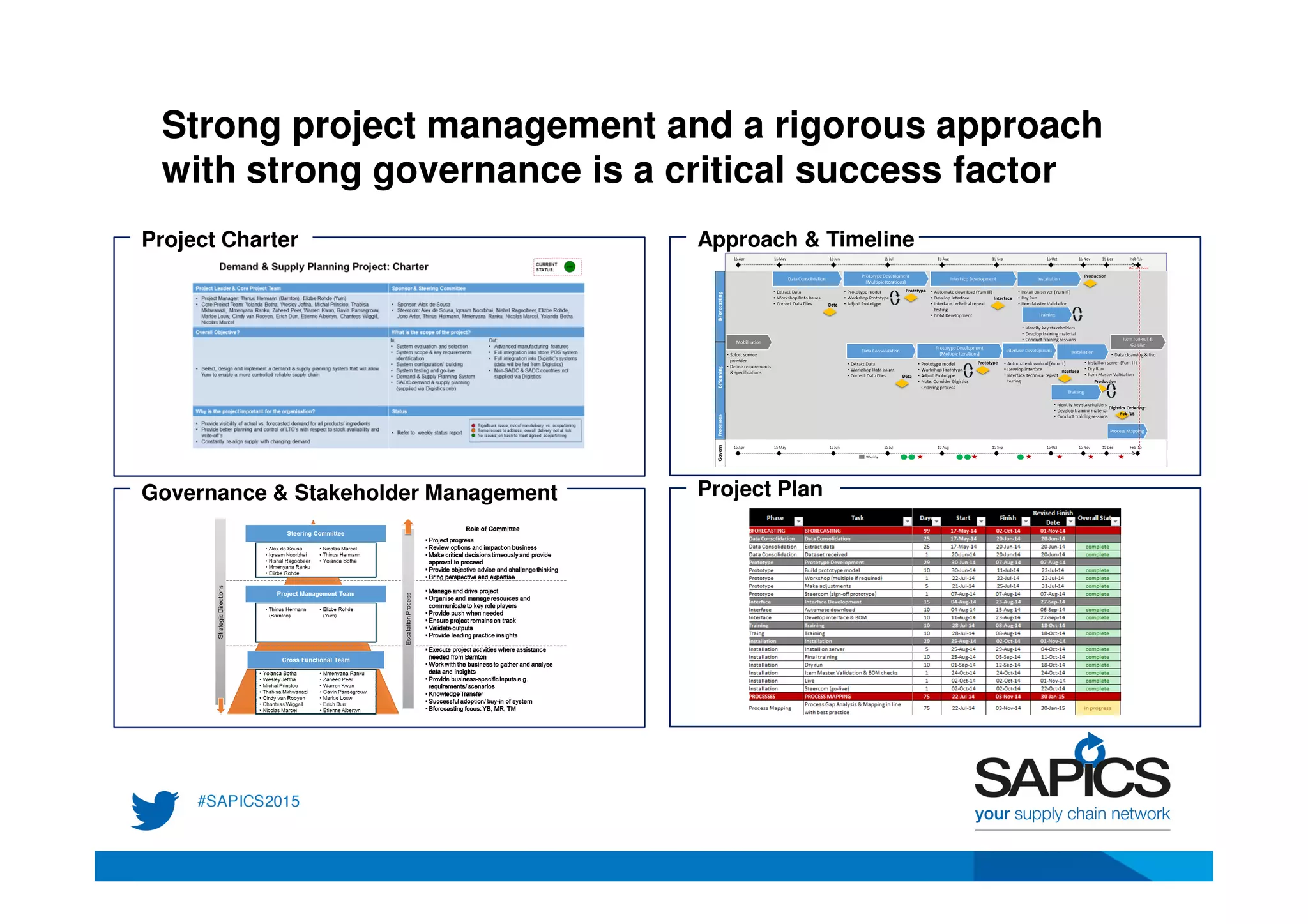

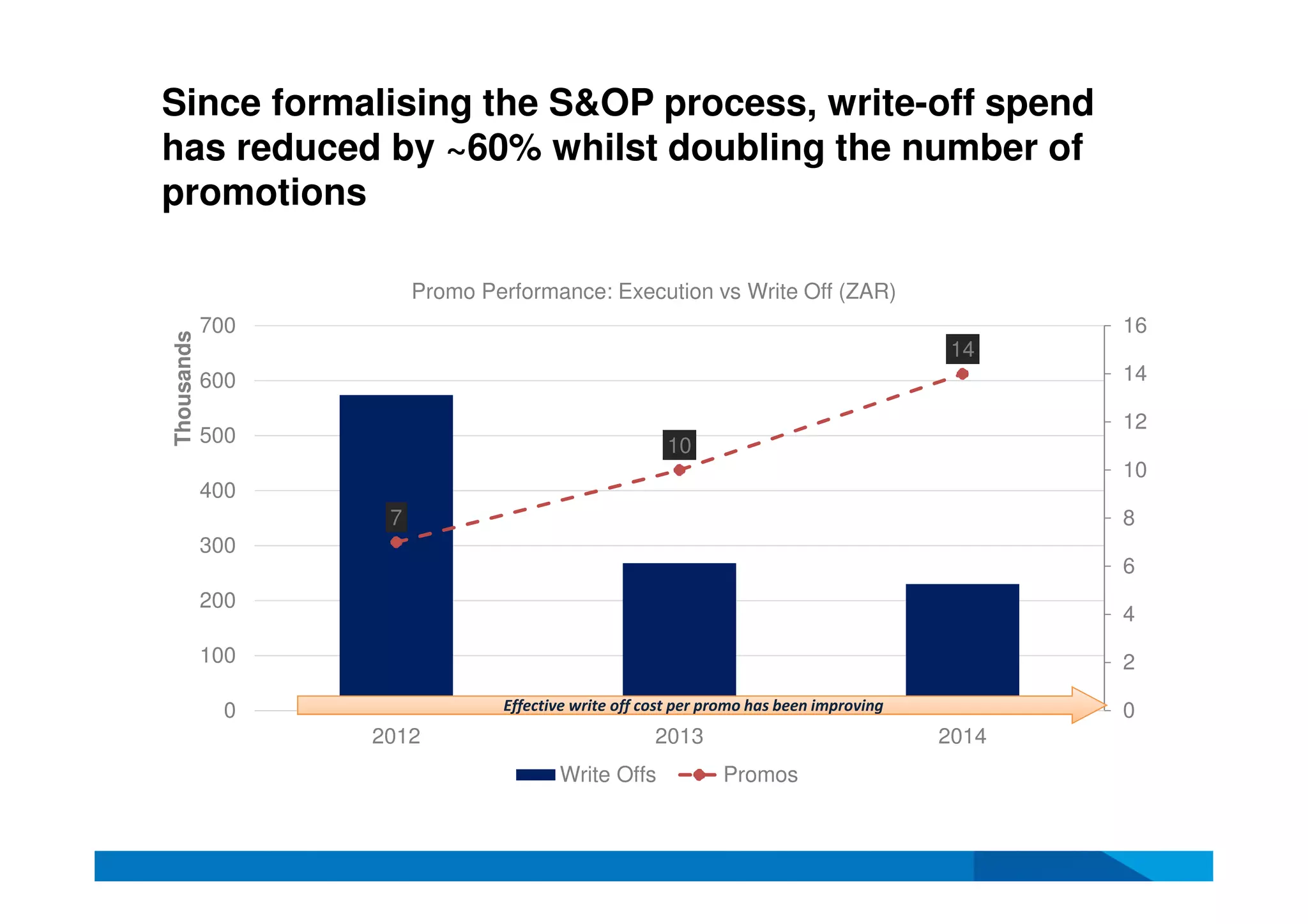

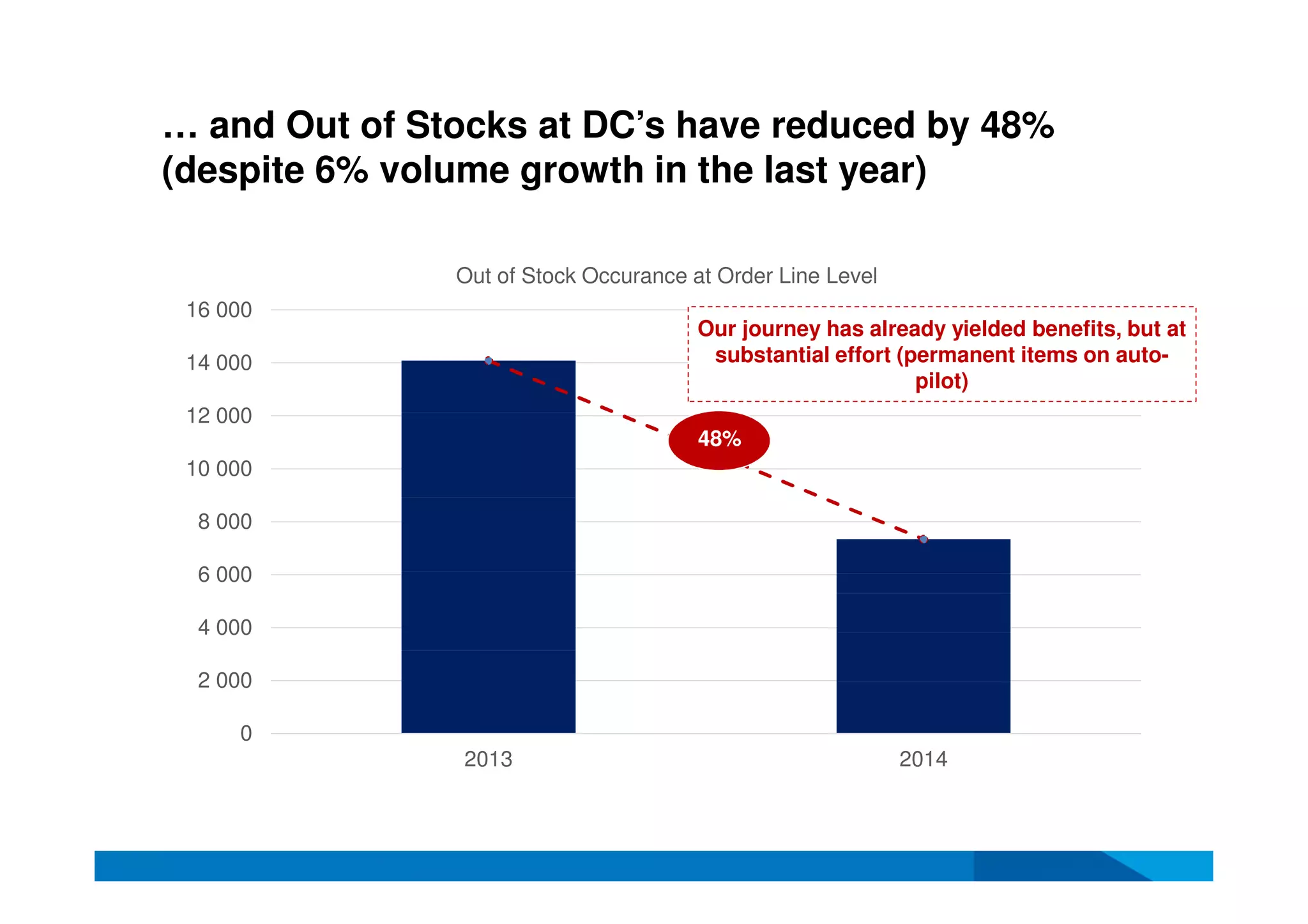

The document details KFC's implementation of a formalized Sales & Operations Planning (S&OP) process to enhance supply chain efficiency in South Africa. It highlights the challenges and complexities of forecasting demand in the quick-service restaurant industry, emphasizing the need for better planning and increased automation to improve stock availability and reduce waste. Key achievements include a significant reduction in write-offs by approximately 60% and improved out-of-stock occurrences despite growth in volume.