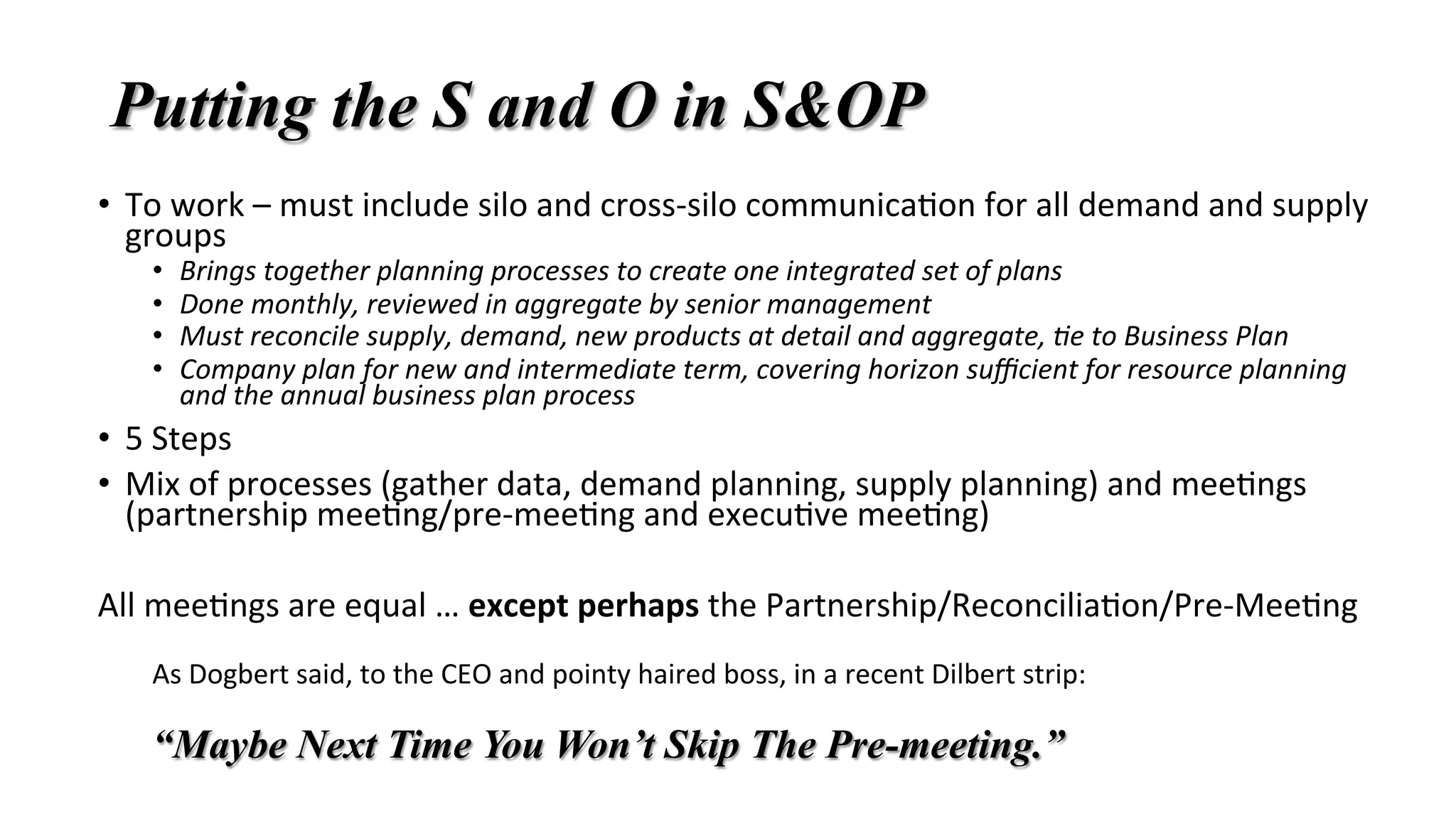

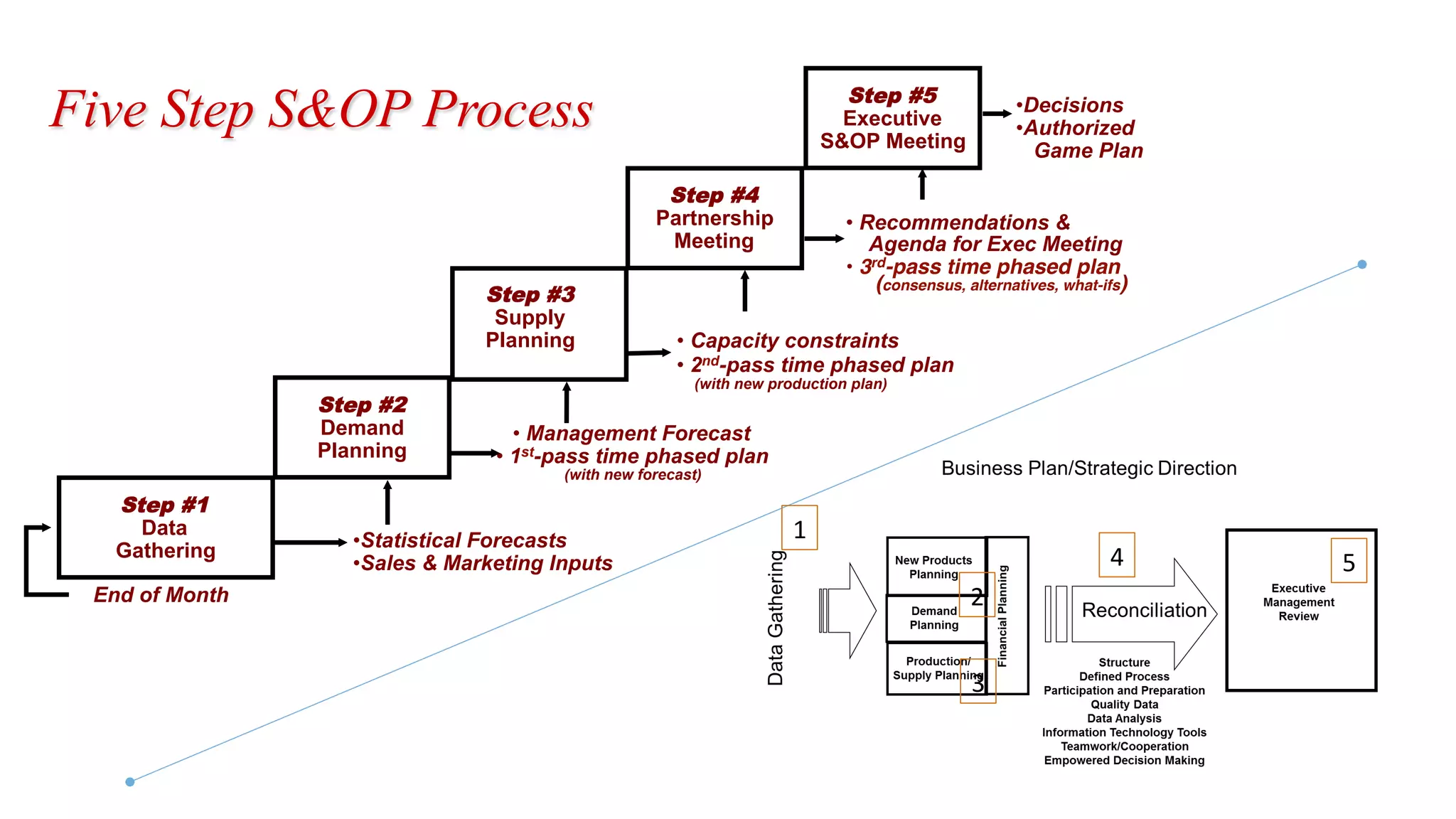

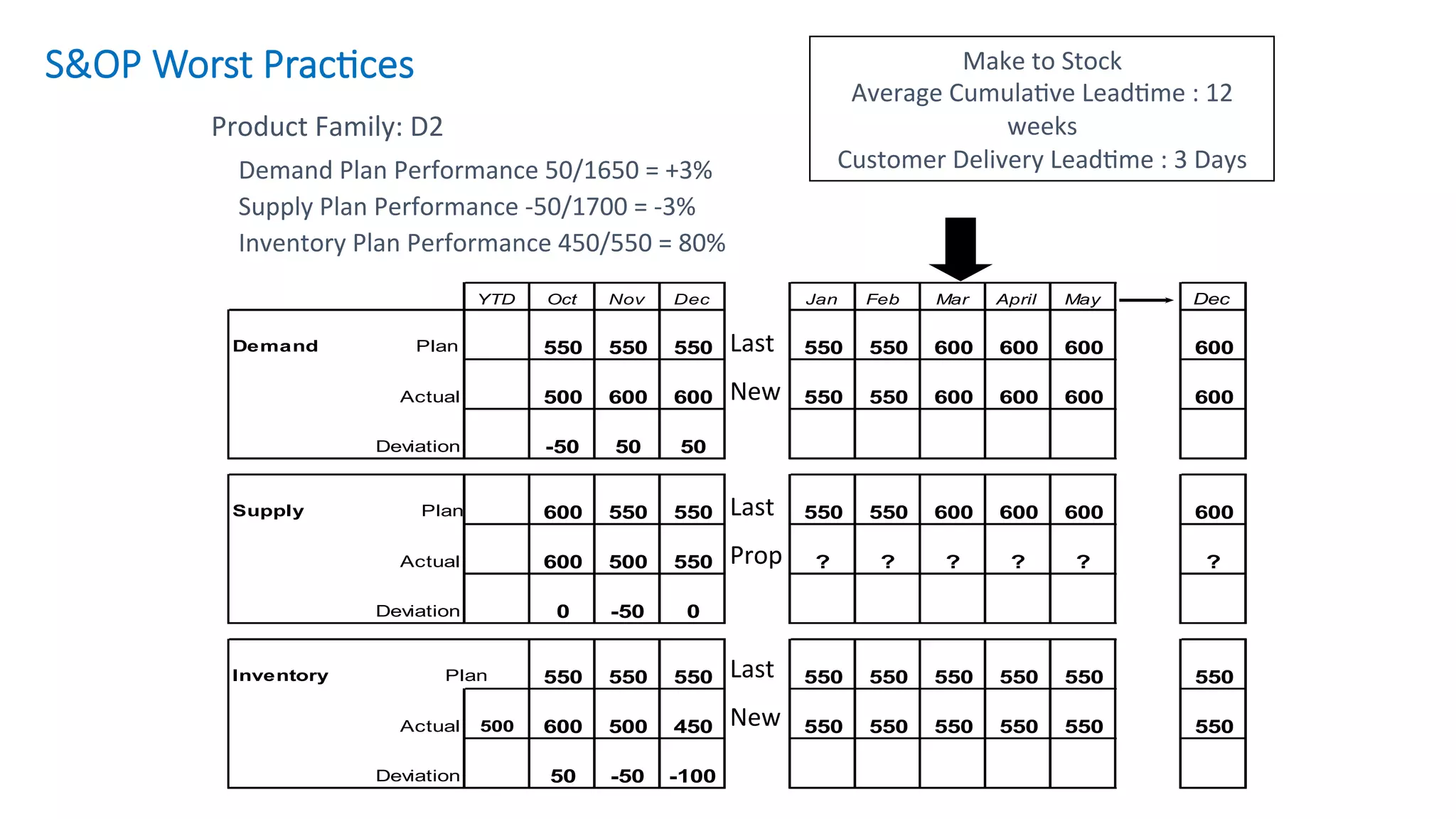

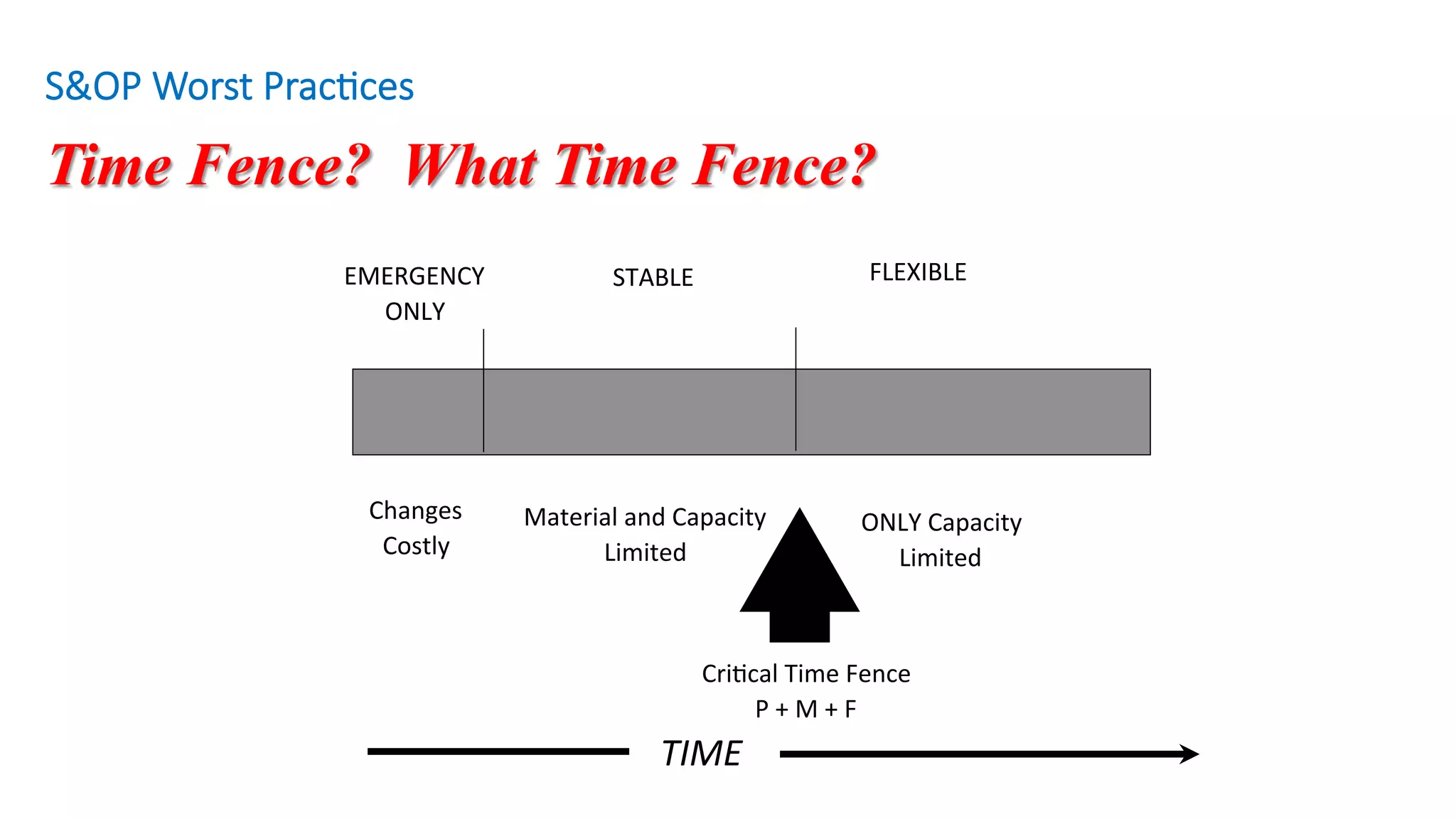

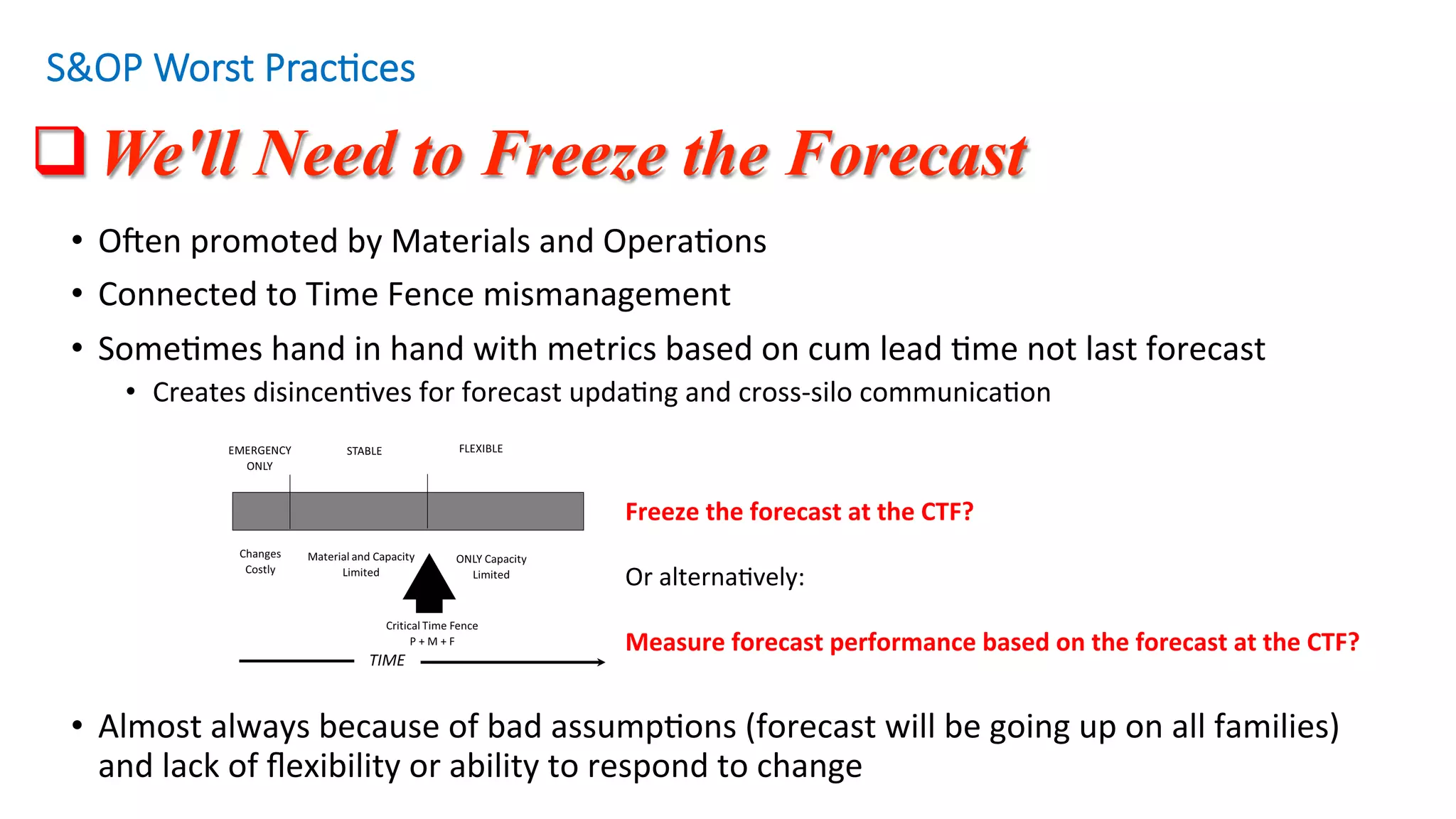

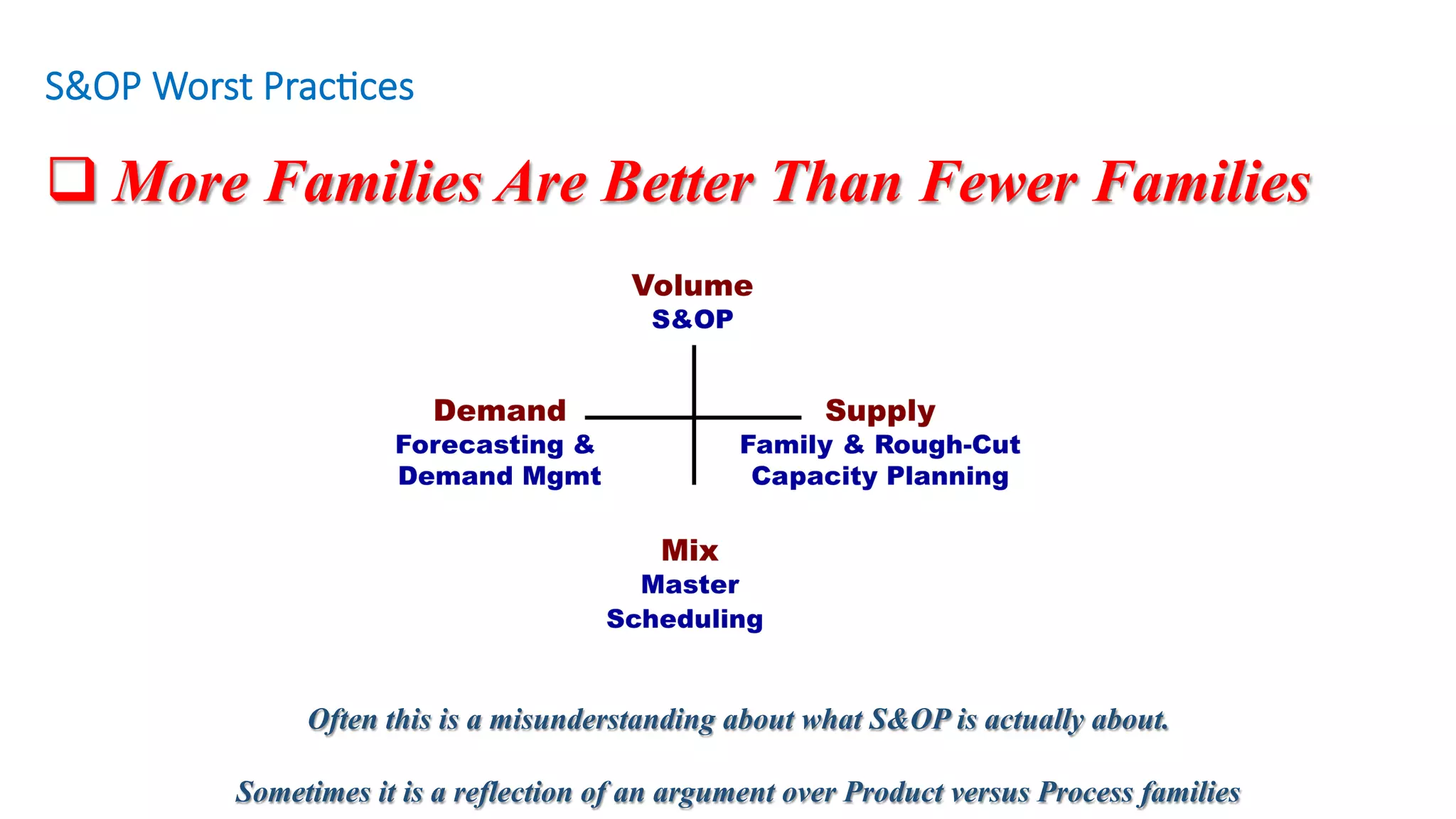

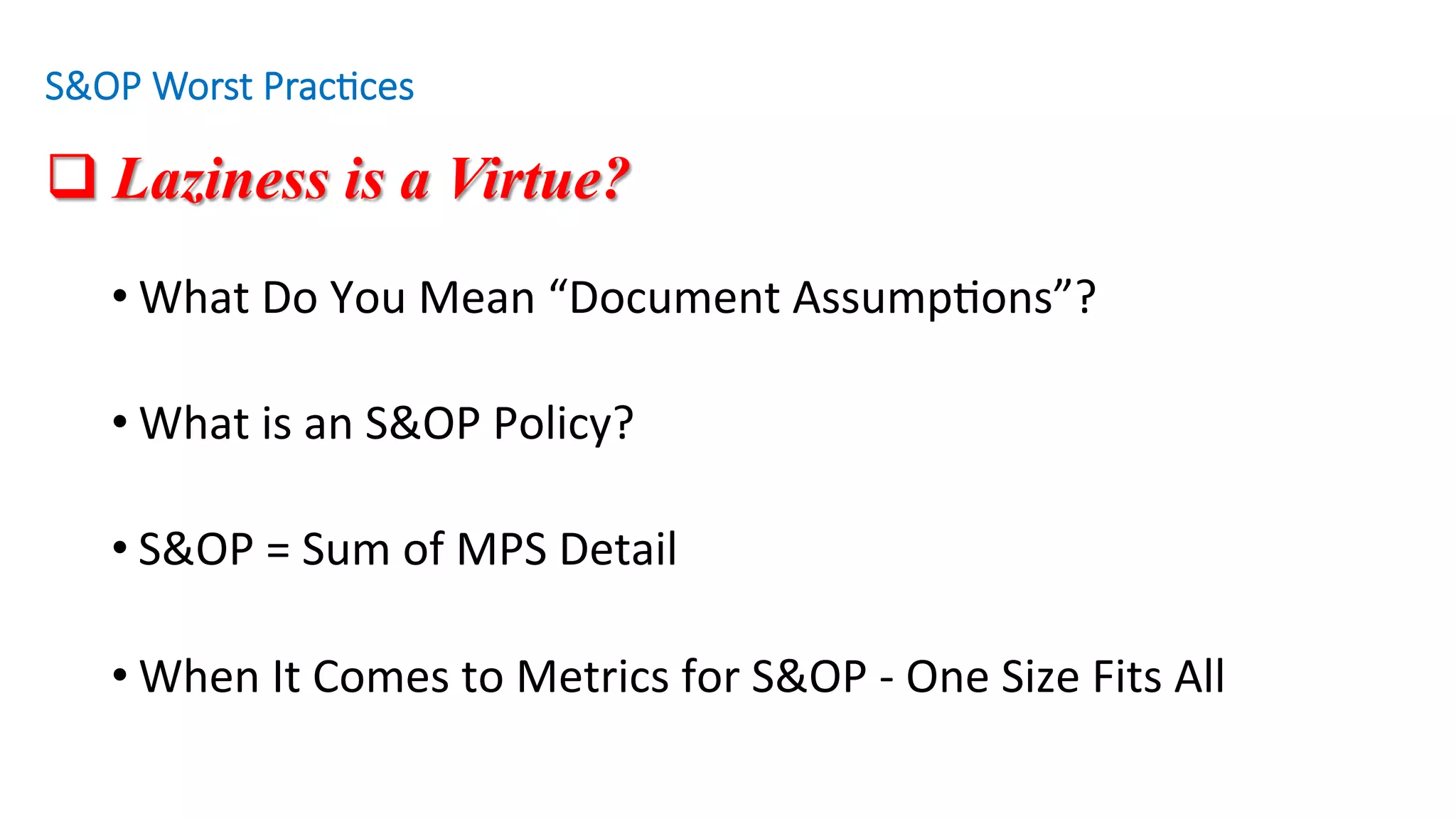

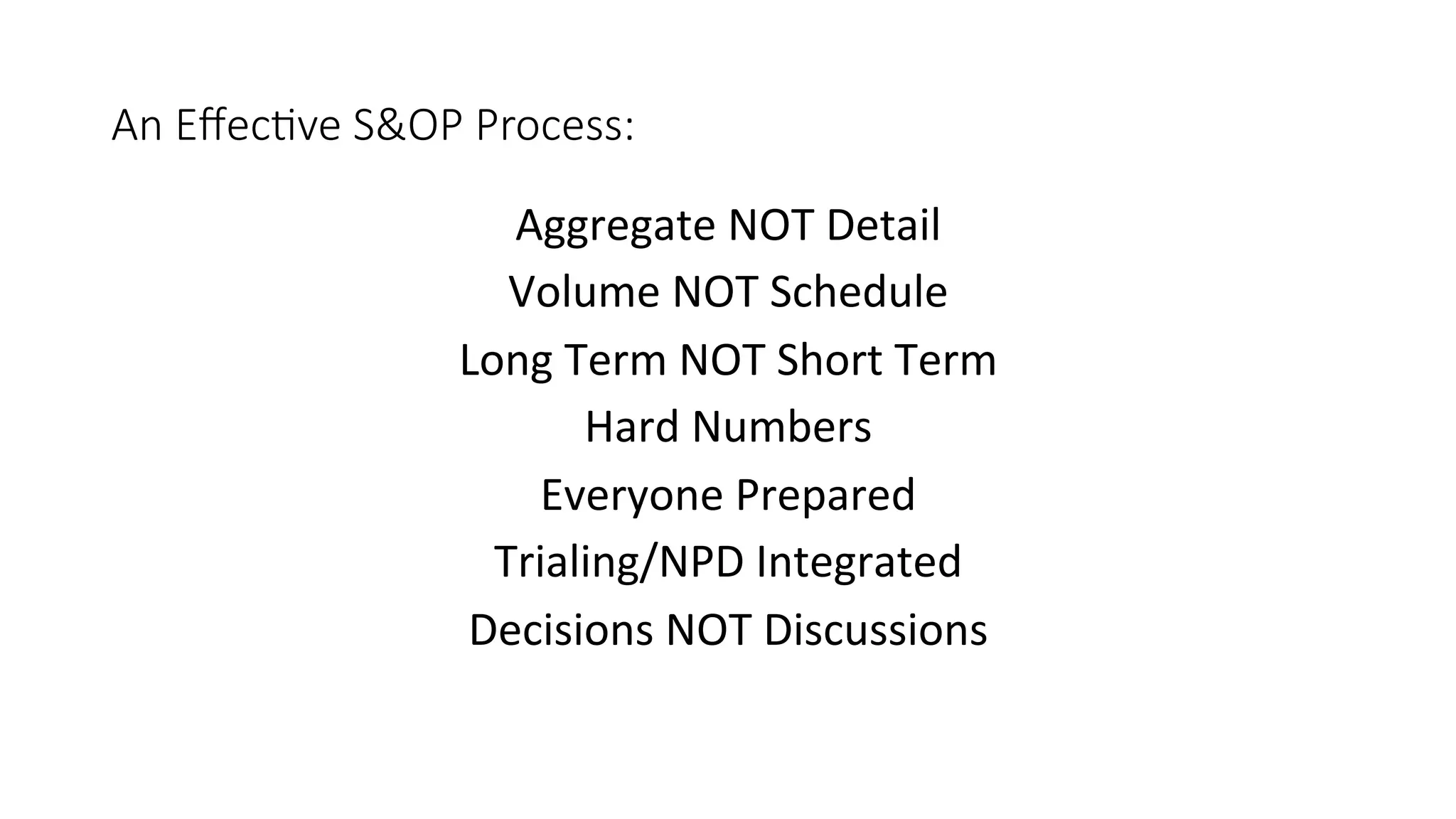

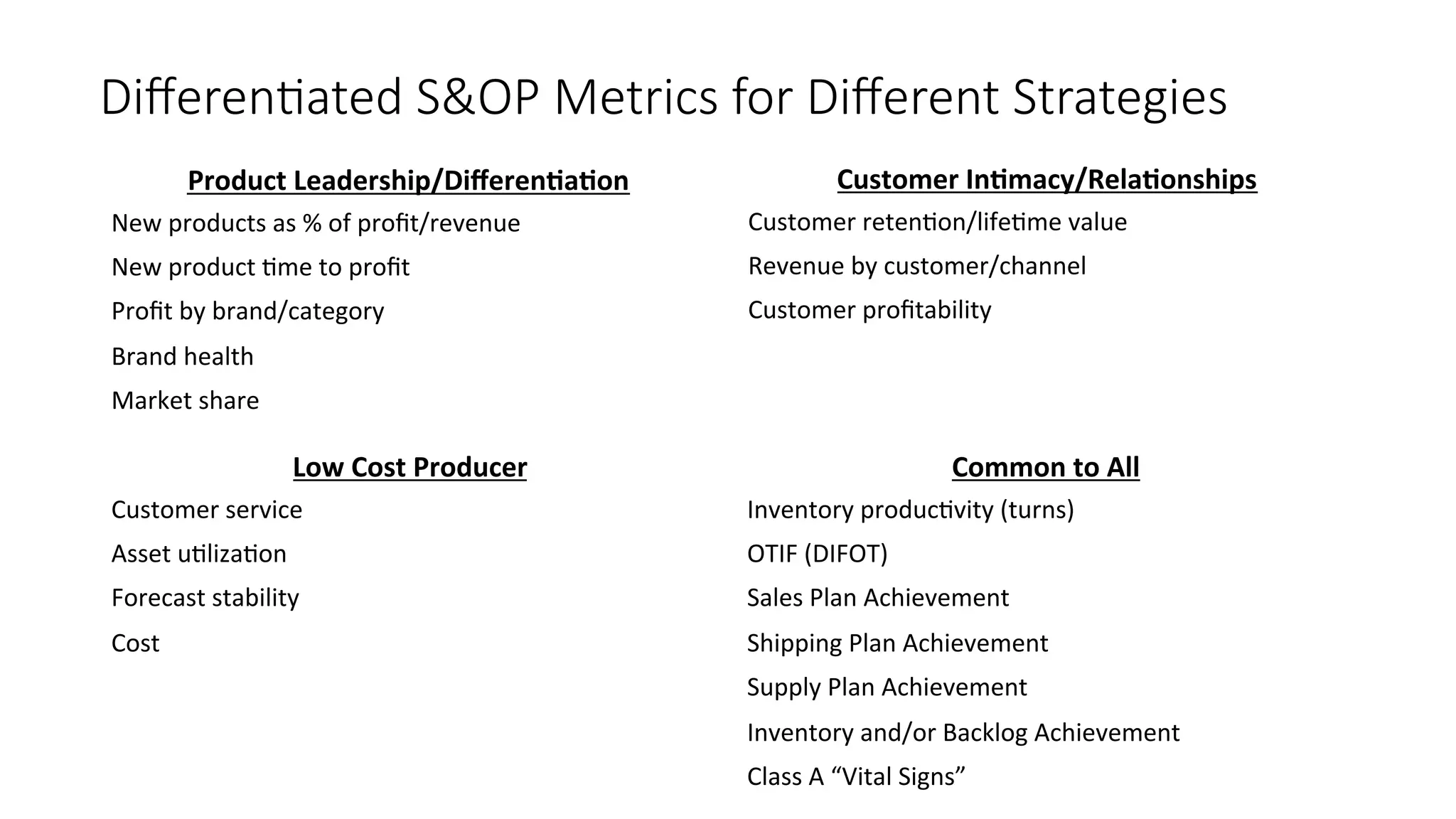

The document discusses the worst practices in sales and operations planning (S&OP), emphasizing the importance of integrating sales, inventory, and operations. It outlines a five-step S&OP process and critiques the reliance on outdated software like Excel, advocating for improved communication and collaboration across departments. Key issues include poor data management, misalignment of forecasts with actual performance, and the need for more effective metrics tailored to different strategies.