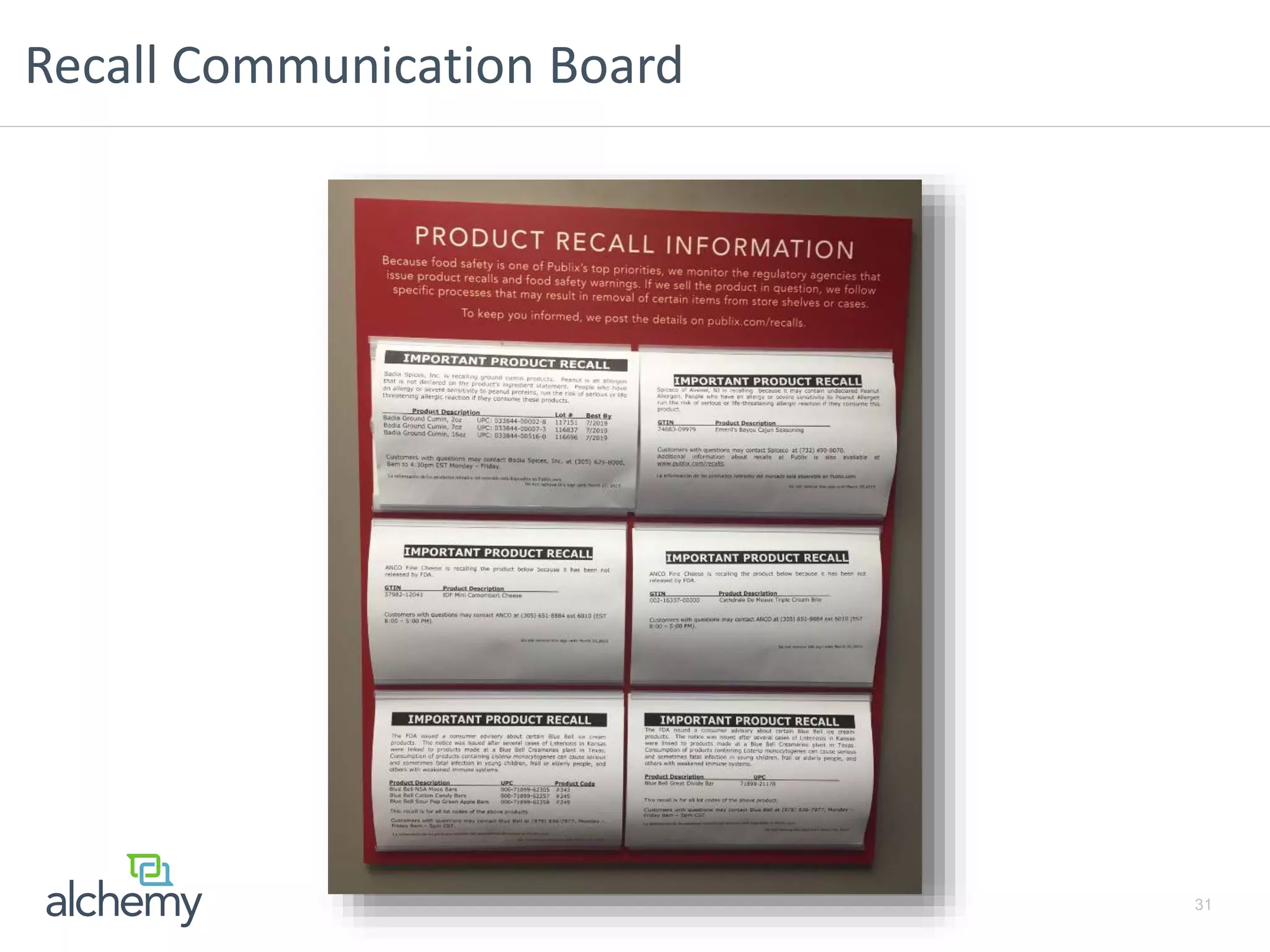

The webinar discusses the essential partnership between suppliers and retailers in managing food recalls, highlighting the significant cost and frequency of recalls caused primarily by allergens. Best practices for preventing recalls include effective food safety systems, internal audits, and transparent communication during incidents. The session also covers regulatory developments and insights from major retailers like Publix on recall management and consumer communication.