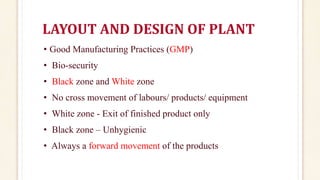

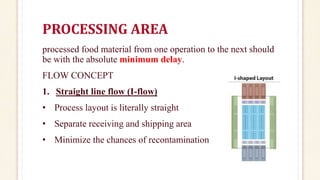

The document outlines key considerations for designing a food processing plant, including the transformation of agricultural products, the importance of hygiene, and compliance with regulations. It details requirements for facilities, such as effective ventilation, appropriate flooring and drainage systems, and designated zones for clean and unhygienic areas to ensure food safety. Additionally, employee welfare amenities and efficient layout designs are emphasized to maintain a productive and safe working environment.