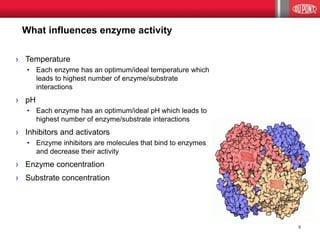

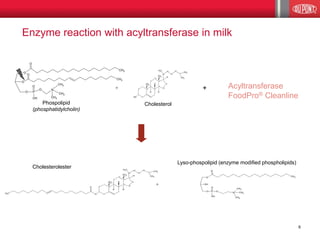

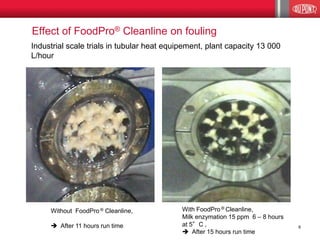

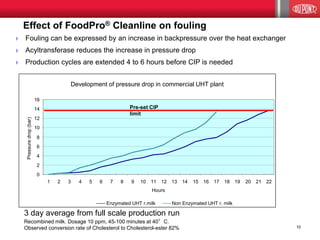

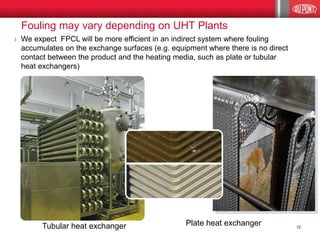

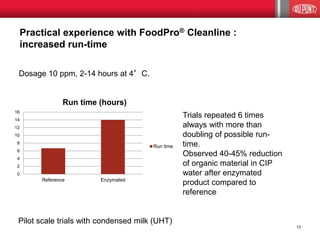

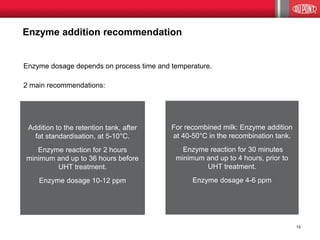

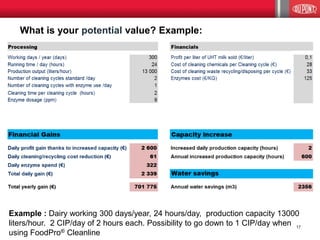

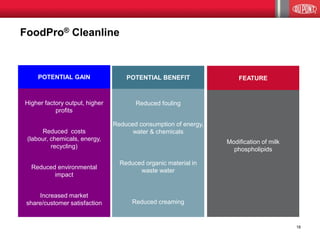

The document discusses the benefits of using the foodpro® cleanline enzyme glycerophospholipid cholesterol acyltransferase (gcat) in milk processing, which reduces free cholesterol and improves emulsion stability while preventing protein aggregation. The enzyme minimizes fouling in UHT milk production, leading to longer run times, reduced cleaning costs, and improved quality of the final product. Practical experience shows significant operational benefits, including higher factory output and lower environmental impact.