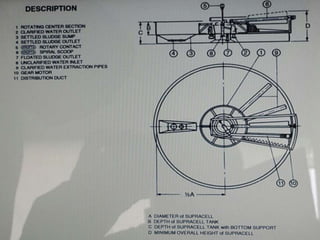

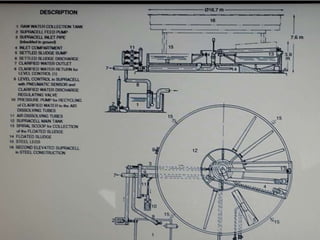

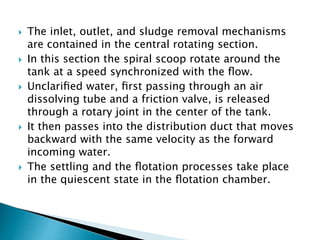

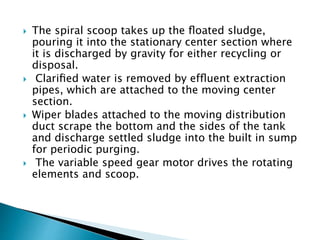

This document summarizes a presentation on flotation processes for wastewater treatment. It discusses how flotation works to separate solids from water by decreasing density. It also describes the components of a flotation system and challenges like rising sludge and bulking sludge. The author argues that using a high rate dissolved air flotation unit before sedimentation can help address these issues and improve effluent quality and plant efficiency compared to conventional activated sludge alone.