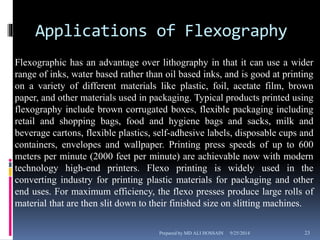

The document discusses the history and evolution of flexography, a modern letterpress printing technique. Originally developed in England using aniline oil-based inks, flexography was initially used for food packaging printing. Since the 1990s, advances in platemaking and inks have improved print quality and expanded flexography's applications. Modern flexography uses photopolymer plates instead of rubber plates, and water-based or UV-curing inks instead of traditional solvent-based inks, reducing air pollution. Flexography is commonly used today for printing labels, food containers, flexible packaging, and corrugated boxes.

![References

Wikipedia [Flexography] –

http://en.wikipedia.org/wiki/Flexography

Accessed 21 January 2013

eHow [Flexography Printing Characteristics] -

http://www.ehow.com/info_8475499_flexography-printing-characteristics.html

Accessed 21 January 2013

ScienceDirect [A review of printing and coating techniques] -

http://www.sciencedirect.com/science/article/pii/S0927024808003486

Accessed 21 January 2013

TNT FlexPak [Technical Questions about Flexography and Flexible Packaging] -

http://www.flexpak.co.th/about/faq_technical

Accessed 21 January 2013

Prepared by MD ALI HOSSAIN 9/25/2014 25](https://image.slidesharecdn.com/flexography-140925002450-phpapp02/85/Flexography-25-320.jpg)