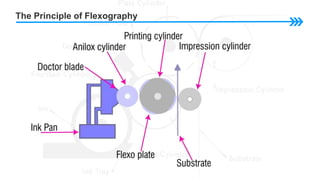

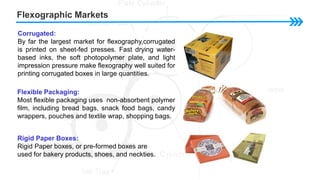

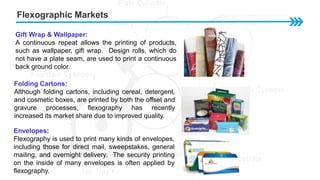

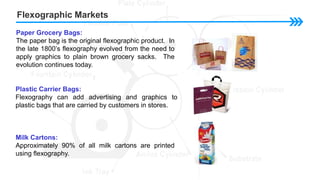

The document provides information about flexography printing. It discusses that flexography has grown approximately 8% per year over the last three decades, making it well-suited for printing on various substrates like coated and uncoated paper, plastic films, and more. Flexography uses a flexible printing plate to transfer ink in a relief process directly from the plate to the substrate with minimal pressure. It is widely used in packaging industries like corrugated boxes, flexible packaging, rigid boxes, and more.