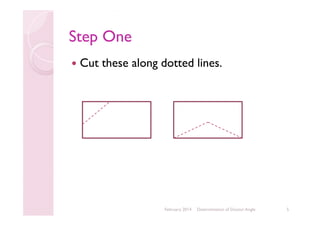

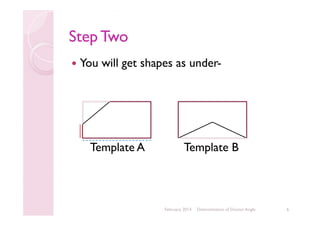

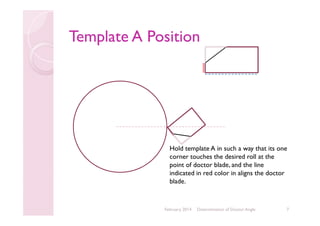

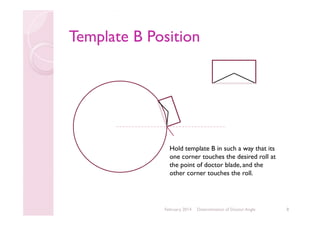

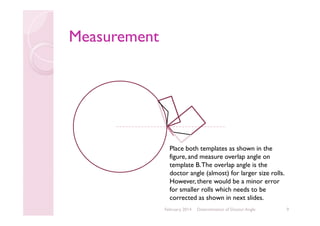

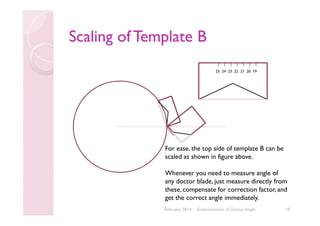

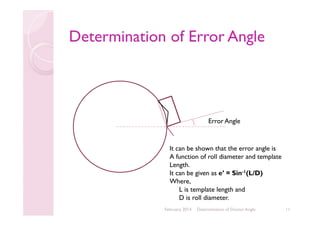

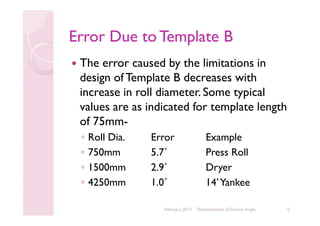

This document presents a simple method for determining the angle of a doctor blade on any roll using two templates. Template A is placed with one corner touching the roll and doctor blade, while Template B is placed with one corner also touching the roll and doctor blade. The overlap angle between the templates indicates the doctor blade angle. For smaller rolls, there is a minor error that can be corrected using a scaling on Template B or a calculated error angle formula based on template length and roll diameter. Measuring the angle using this method provides a starting point, and the supplier's guidelines should be checked to ensure the correct doctor blade angle.