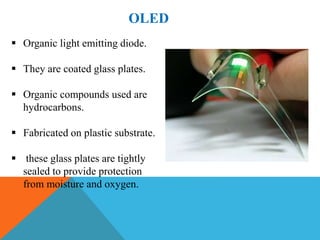

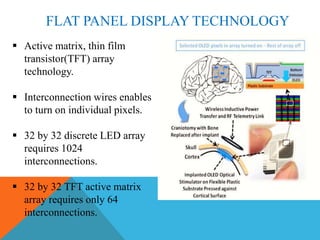

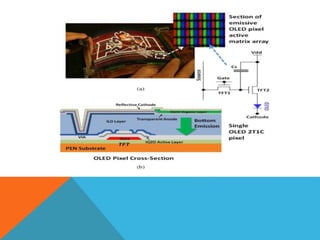

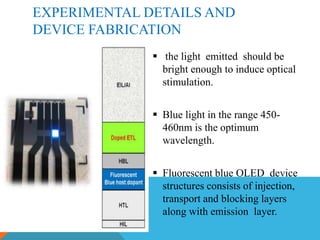

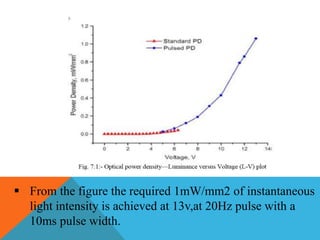

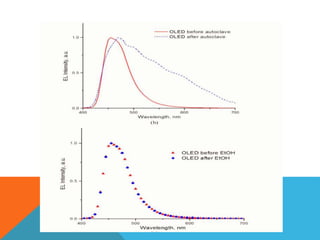

Flexible OLED displays can be used for optogenetics by selectively activating neurons through individual pixels on a thin, biocompatible plastic substrate. The document describes how a flexible OLED display was fabricated using organic light-emitting diodes and a thin-film transistor active matrix array on a 125 micrometer plastic substrate. Experimental results showed the flexible OLED display could produce over 1mW/mm2 of blue light intensity needed for optical stimulation through pulsing. Tests also demonstrated the flexible display's biocompatibility for growing cells on its surface.