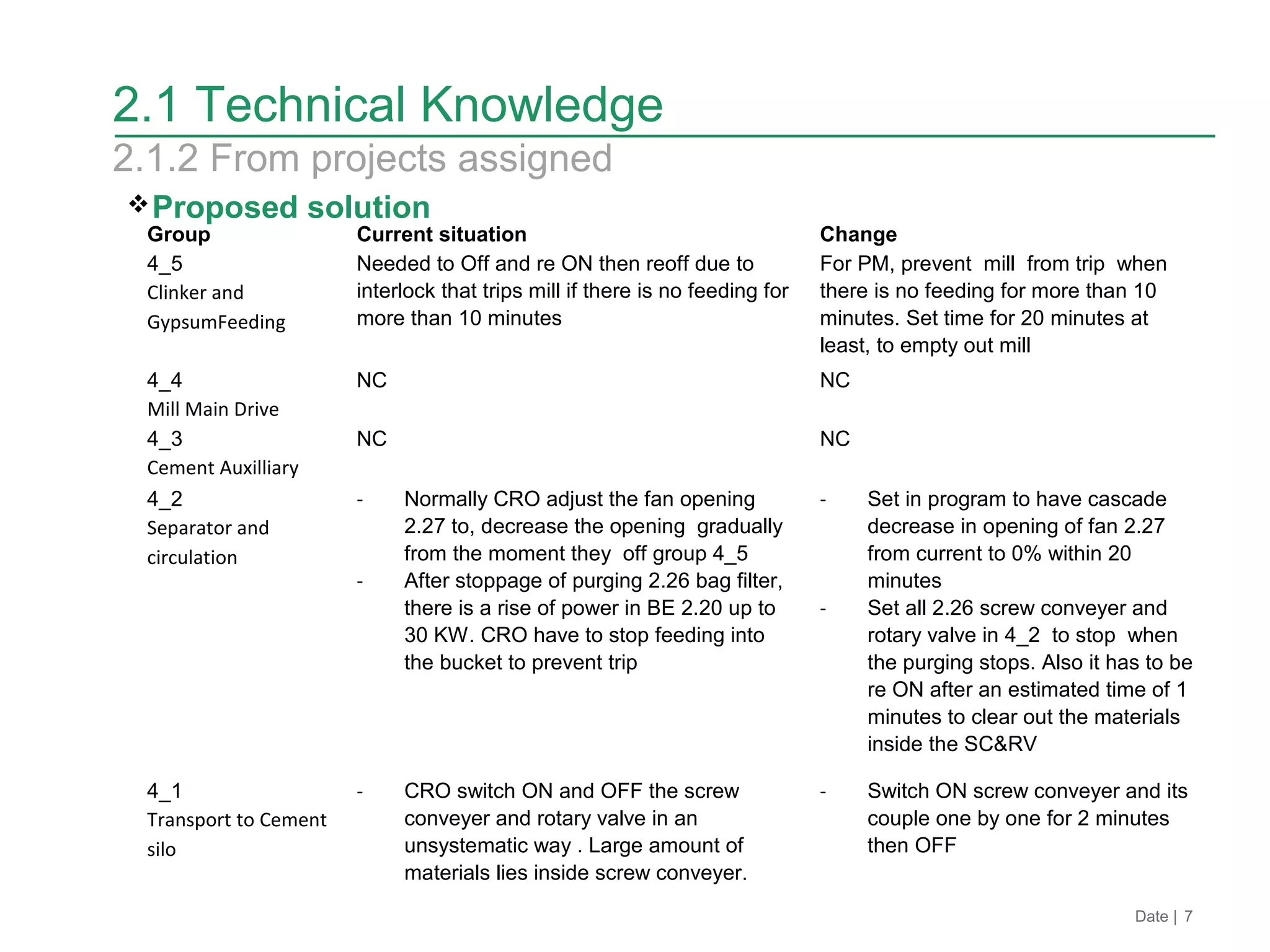

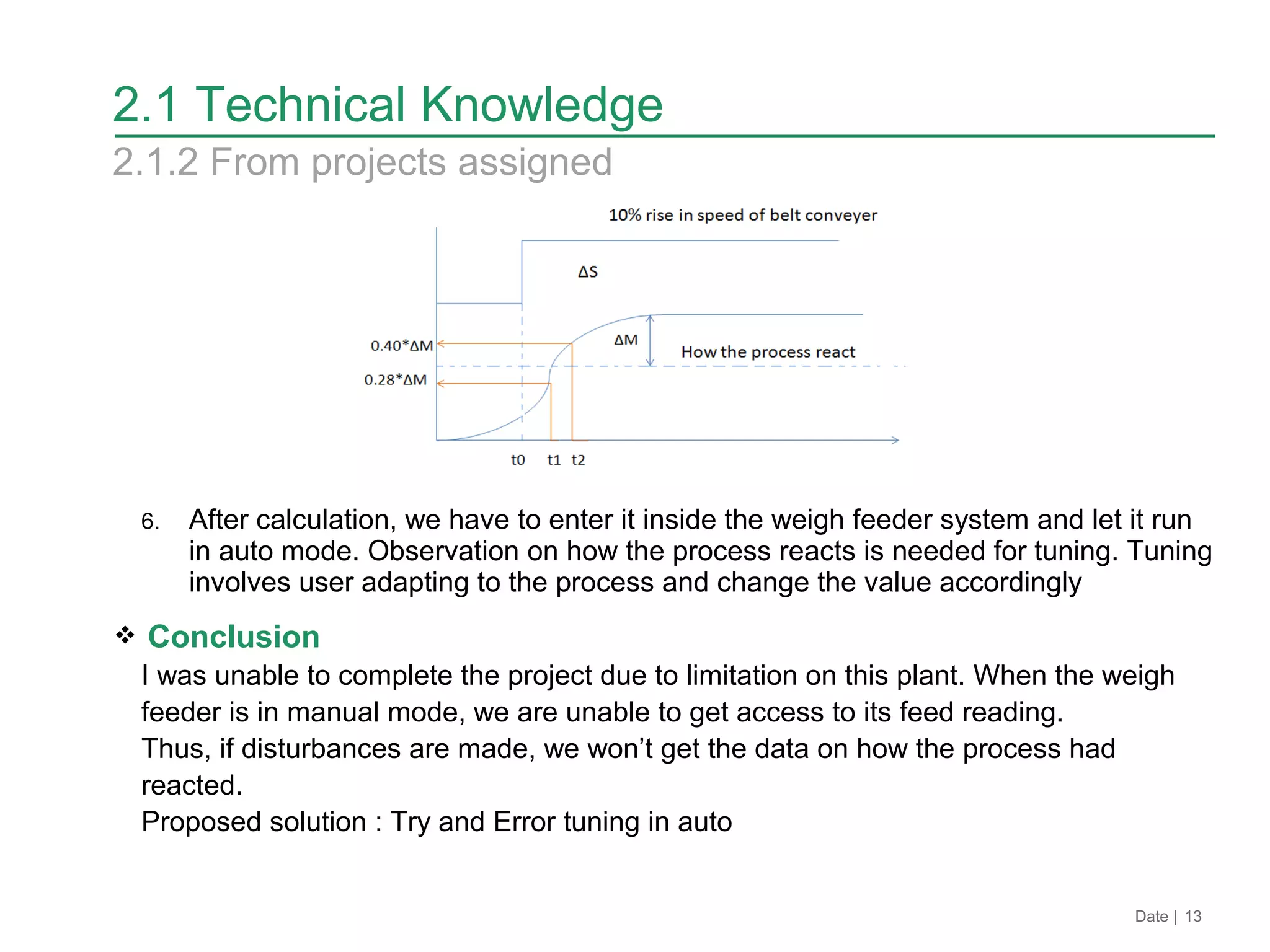

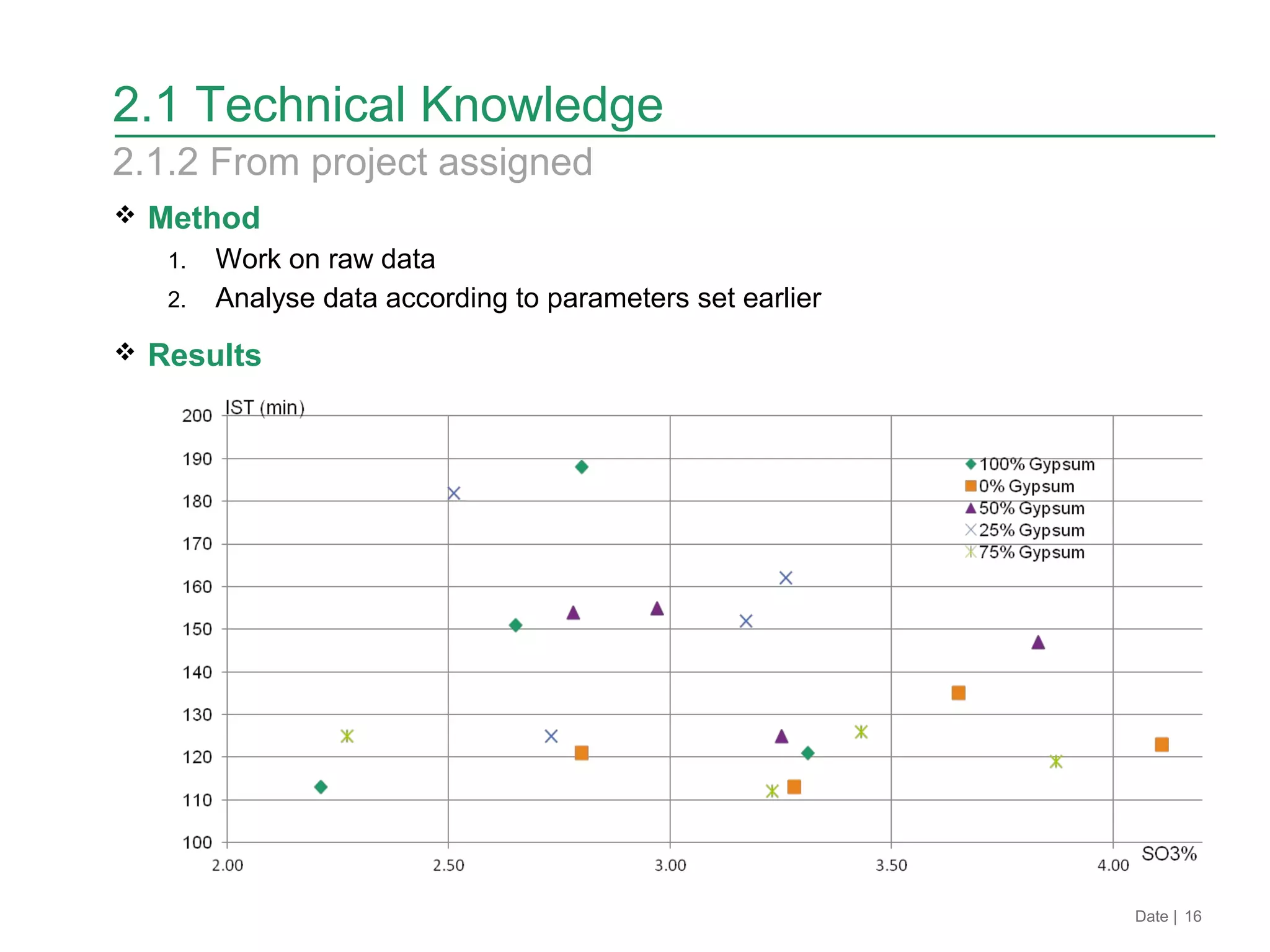

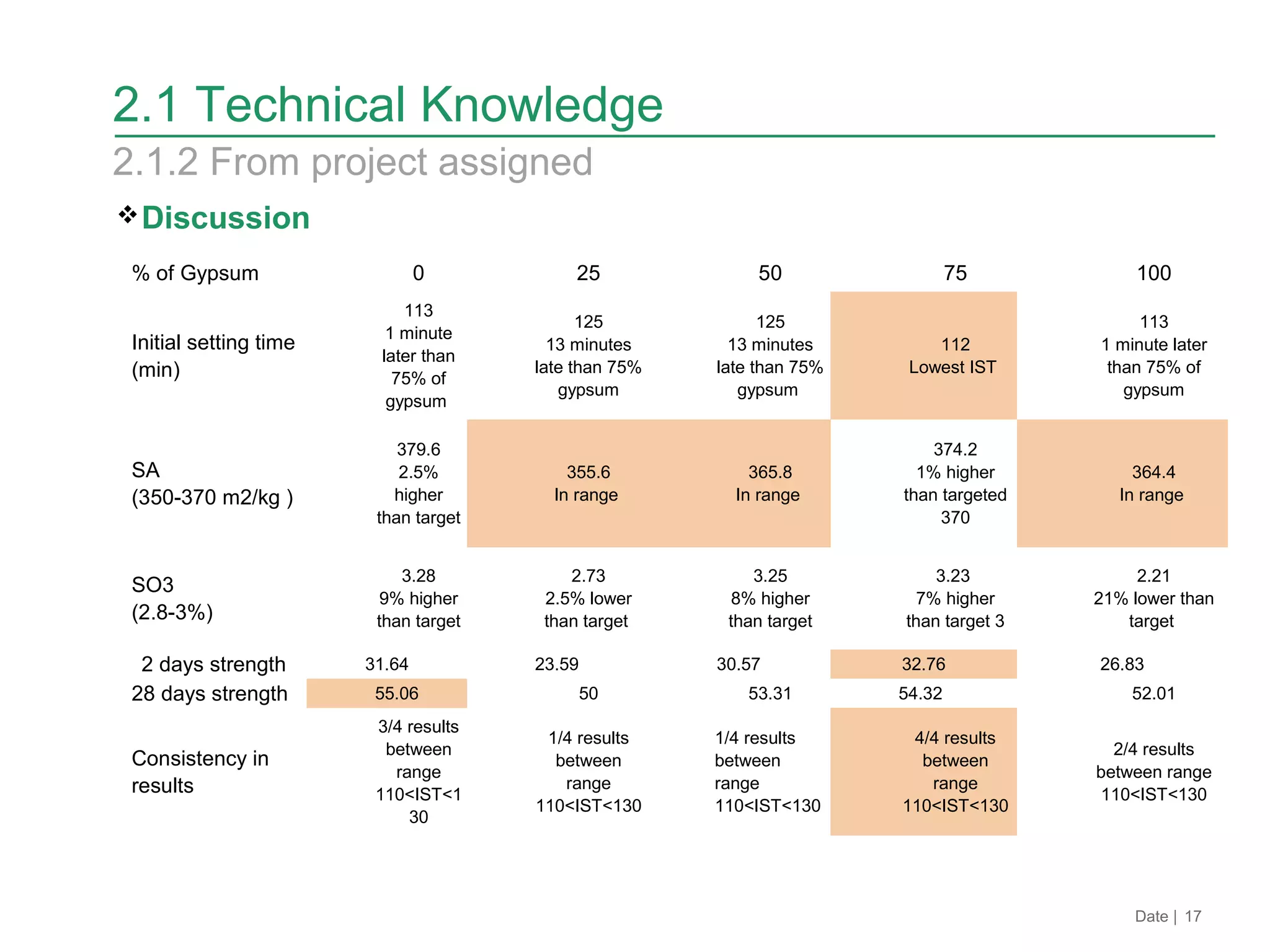

Siti Mardiah completed a 3-month internship from April to July 2015 as an assistant engineer in the process department of Lafarge Pasir Gudang Plant. During her internship, she gained exposure to technical processes like mill and weigh out inspections. She also worked on projects to optimize the plant's shutdown sequence, reduce idling equipment in the silos, and analyze grinding aid and gypsum trials. In addition, she learned non-technical skills like developing professional relationships and improving her attention to detail. Overall, the internship helped her apply her knowledge practically and identify strengths and weaknesses to develop further.