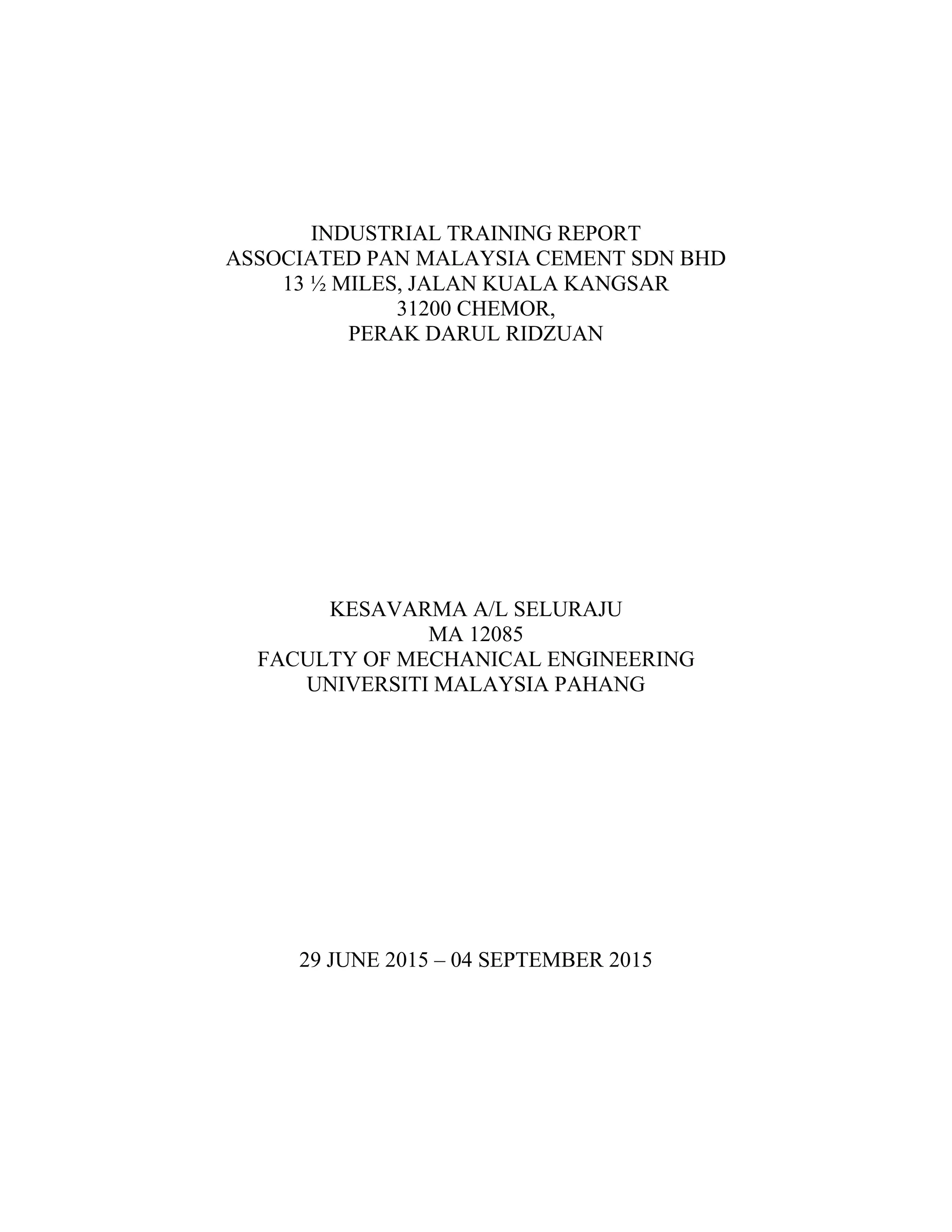

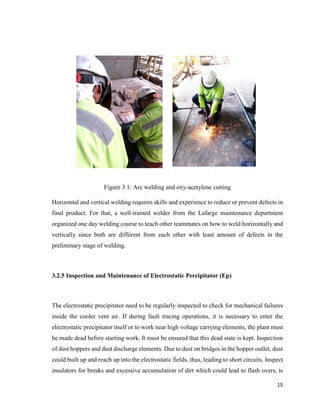

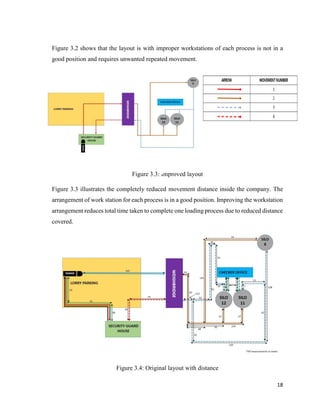

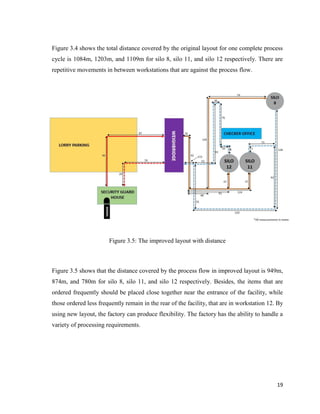

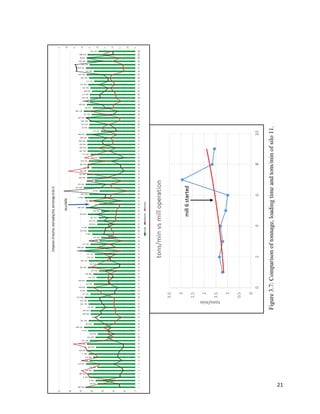

The document is an industrial training report submitted by a student from Universiti Malaysia Pahang who completed a 10-week internship at Associated Pan Malaysia Cement Sdn Bhd. The report provides details of the company background and organization, an overview of cement production processes, and a description of activities performed by the student in different areas of the plant including mechanical repairs, inspection and maintenance of various equipment. It concludes with lessons learned from projects and activities during the training period.