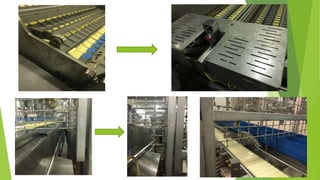

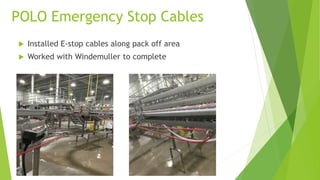

This document describes an operations internship at Campbell MacMillan in Lake Odessa, Michigan. It outlines the intern's goals of gaining knowledge and hands-on learning through completing various projects over the summer. The internship involved 4 weeks of training in different production rooms, followed by focusing on safety projects like addressing unsafe rotating shafts, improving safety guarding around robots, and installing emergency stop cables. Other projects included designing a new auger chute to reduce egg loss, organizing the maintenance department, measuring light intensity, and tracking temperatures in production rooms. The intern expresses gratitude to supervisors and other staff for their support.