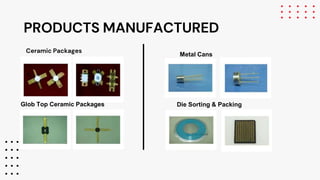

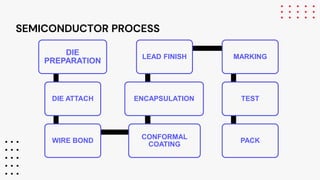

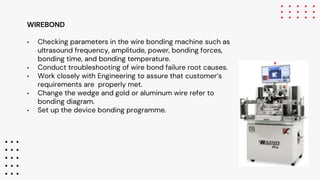

Kiran Nayakar A/L Supramaniam completed a 6-month industrial training program at Semiconductor Assembler and Manufacturer Sdn. Bhd. to gain exposure to real-world engineering. The training objectives were to expose students to engineering professions, facilitate knowledge sharing between students and industry staff, and develop creative/positive thinking for overcoming engineering problems. Kiran learned about the company's semiconductor packaging processes like die preparation, die attach, wire bonding, and encapsulation. His training scope involved machine operation like pick and place, die bonding, wire bonding, and capping. Through the training, Kiran understood the roles of technicians and engineers better and gained skills in time management, goal setting,