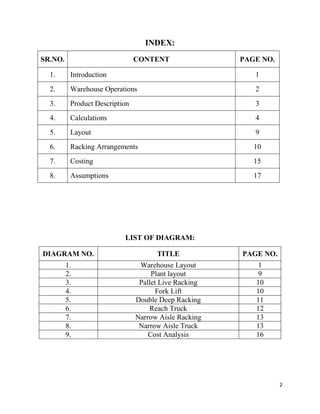

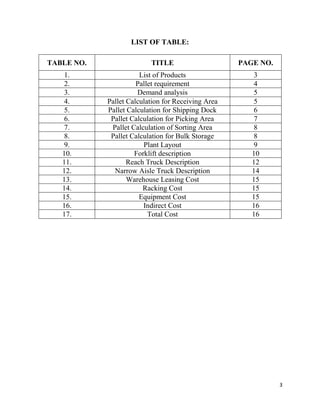

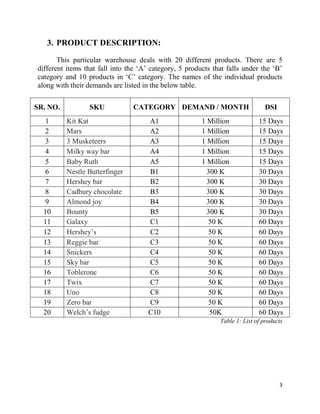

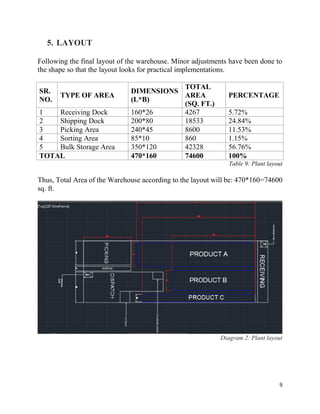

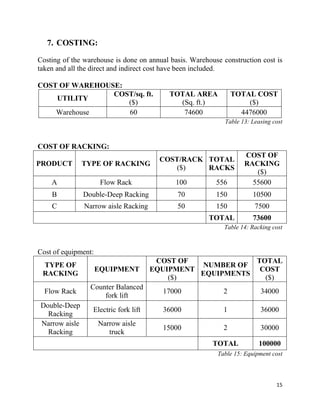

This document provides a warehouse design and layout project for storing 20 different products across 3 categories. It includes calculations for space needed in receiving, shipping, picking, sorting, and bulk storage areas. The receiving area is designed to hold one day of incoming goods. The shipping area is designed to hold 1.5 days of goods. The picking area holds one full day of product for each SKU. The sorting area holds one hour of goods. Bulk storage holds the calculated safety stock levels. The total proposed warehouse area is 74,600 square feet based on the layout and space calculations provided.