Companies need warehouses for several key reasons:

1. To consolidate supplies from multiple vendors and distribute optimized assortments to plants/customers.

2. To create transportation, inventory, and production efficiencies.

3. To pool risks and maintain high service levels.

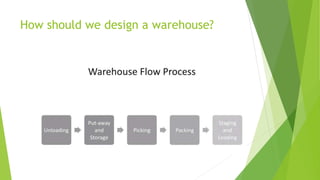

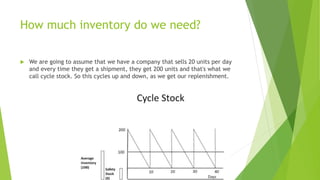

Warehouses should be designed to maximize speed, quality, and productivity through features like shortest product distances, redundancy checks, and automation. Proper inventory management requires determining needs for cycle stock and safety stock to address demand and replenishment uncertainties. Companies must also choose optimal inventory reorder policies like fixed-quantity or variable-quantity ordering.