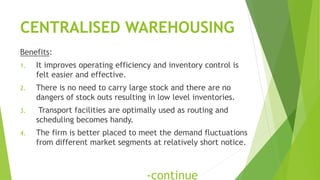

This document discusses warehouse management. It defines warehousing as receiving, storing, and preparing goods for reshipment. Warehouses serve important functions like storage, movement of goods, and preparation for customers. There are different types of warehouses including private warehouses owned by companies and public warehouses available for hire. Key considerations in warehouse design include product flow, space requirements, and location. Centralized and decentralized approaches each have benefits and drawbacks for efficiently serving customer demand.

![ECONOMIC AND SERVICE BENEFIT OF

WAREHOUSING

Economic benefits - Consolidation, Break

bulk, Cross Dock, processing postponement,

stock piling[seasonal storage]

Service benefits - spot stocking,

Assortment, mixing, production support,

market presence](https://image.slidesharecdn.com/warehouse-211004044150/85/Warehouse-5-320.jpg)

![Consolidation

warehouse

Plant B

[Product B for

Customer X]

Plant C

[Product C for

Customer X]

Customer X

[Product A+

Product B+

Product C]

Plant A

[Product A for

Customer X]

CONSOLIDATION](https://image.slidesharecdn.com/warehouse-211004044150/85/Warehouse-7-320.jpg)

![Plant A

[Product A

for

Customers

X+Y+Z]

Break bulk

warehouse

Customer

X

Customer

Y

Customer

Z

BREAK BULK WAREHOUSE](https://image.slidesharecdn.com/warehouse-211004044150/85/Warehouse-8-320.jpg)

![CROSS DOCK WAREHOUSE

Plant A

[Product A]

For

W, X, Z

Plant B

[Product B]

For

W,X,Y,Z

Cross Dock

warehouse

Customer W

[A+B+C]

Customer X

[A+B]

Customer Y

[B+C]

Customer Z

A+ C

Plant C

[Product C]

For

W, Y, Z](https://image.slidesharecdn.com/warehouse-211004044150/85/Warehouse-9-320.jpg)

![In transit mixing

Warehouse

[transit mixing point,

mix & make product

C]

Plant A

[Product A]

Plant B

[Product B]

Customer X

Products

A+ B+ C

Customer Y

Products

A+B

TRANSMIT MIXING WAREHOUSE](https://image.slidesharecdn.com/warehouse-211004044150/85/Warehouse-11-320.jpg)

![MANUFACTURING WAREHOUSE

Manufacturing

Warehouse

Vendor A

[part A]

Vendor B

[part B]

Vendor C

[part C] Assembly Line X

Assembly Line Y

Assembly Line Z](https://image.slidesharecdn.com/warehouse-211004044150/85/Warehouse-12-320.jpg)