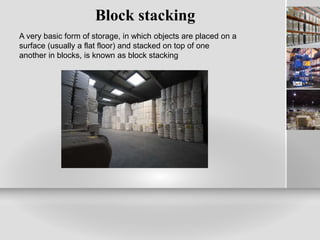

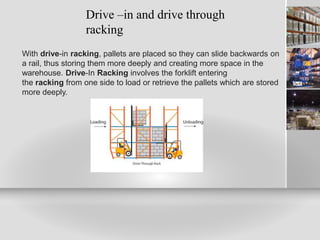

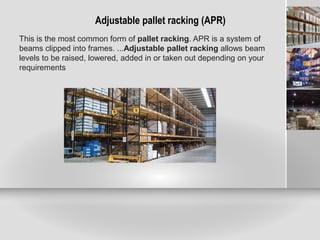

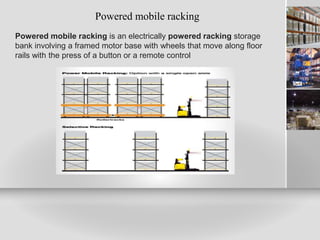

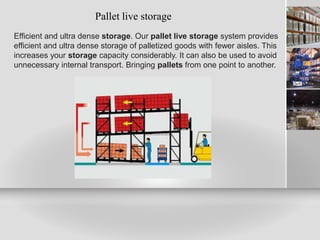

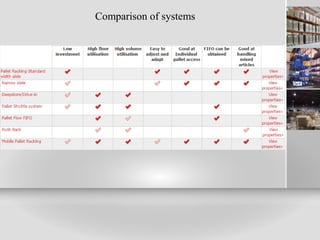

This document discusses various systems for palletized storage and handling in a warehouse. It describes common types of pallet movement including hand pallet trucks, powered pallet trucks, tugs and tractors, conveyors, and automated guided vehicles. It also discusses pallet stacking techniques and different types of storage systems for palletized goods such as block stacking, drive-in and drive-through racking, push-back racking, adjustable pallet racking, double deep racking, narrow aisle racking, powered mobile racking, pallet live storage, and automated storage and retrieval systems. Forklifts used for palletized storage include counterbalanced forklifts, reach trucks, and stacker trucks.