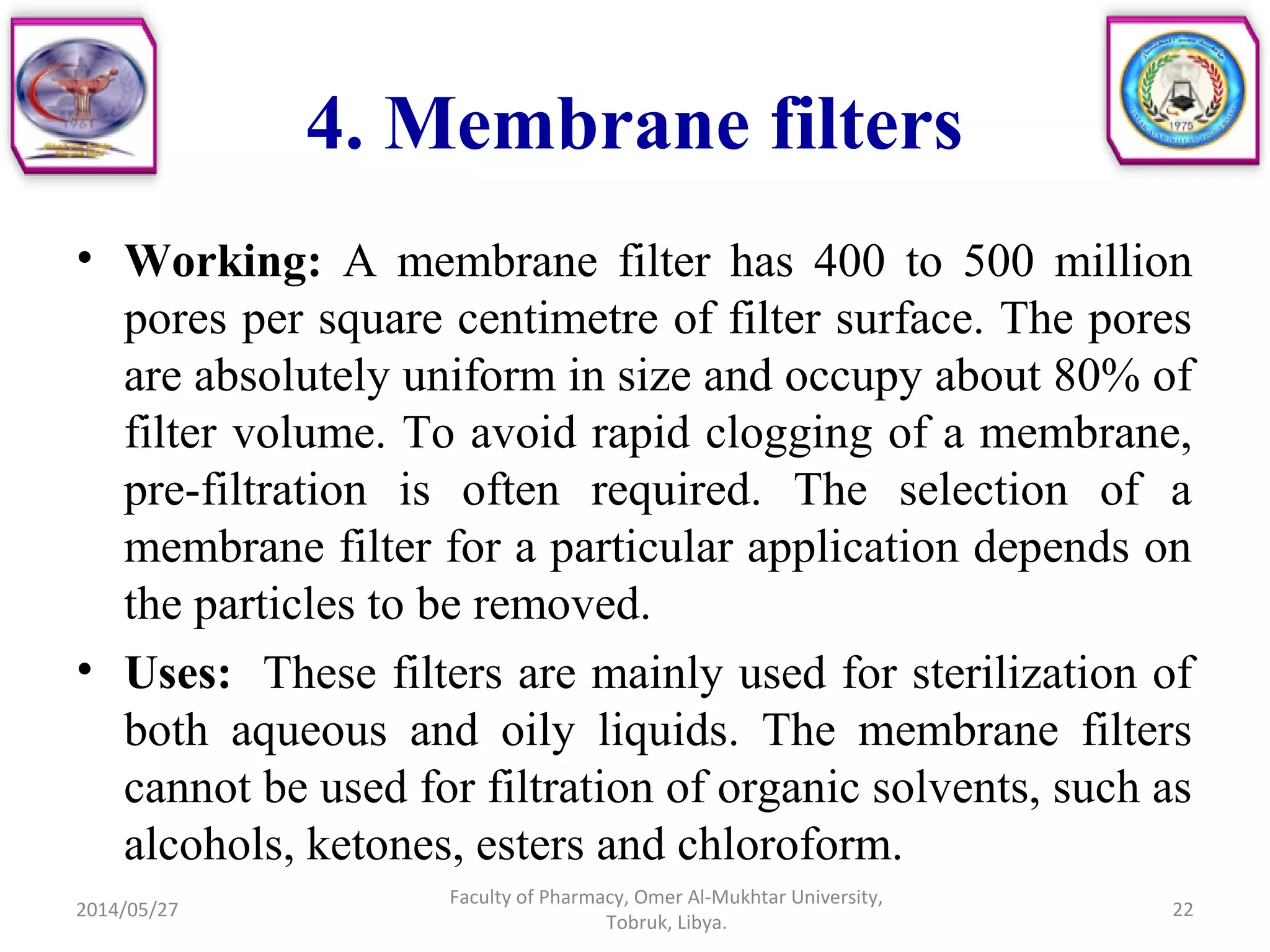

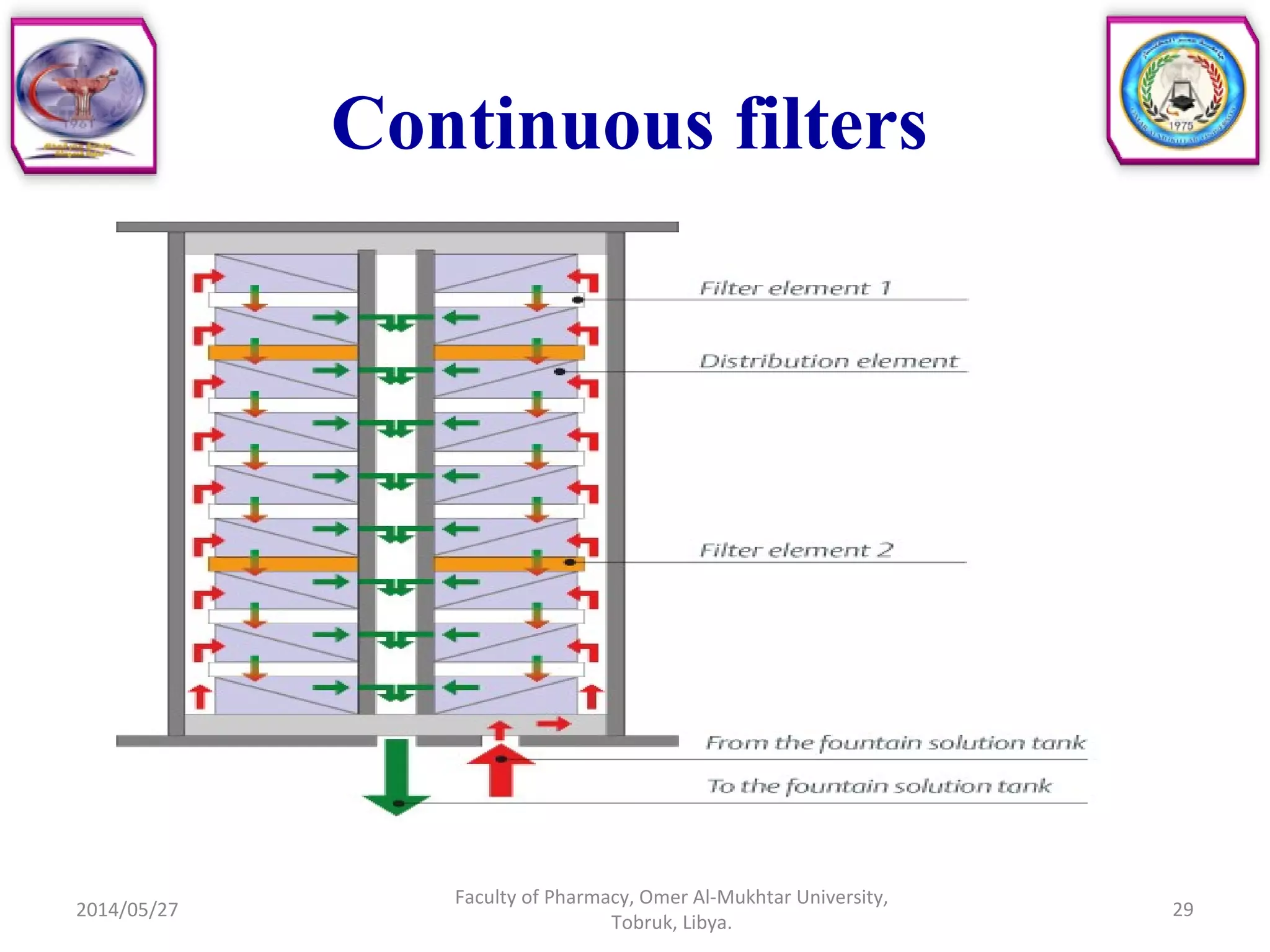

The document discusses various aspects of filtration including definitions, applications, factors affecting filtration, theories of filtration such as Darcy's law and Kozeny-Carman equation. It also describes different types of filtration equipment used in the pharmaceutical industry such as filter presses, membrane filters, filter candles and sintered filters. Continuous filters are also discussed which involve continual washing of filter media.