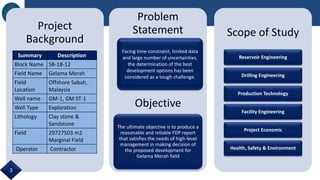

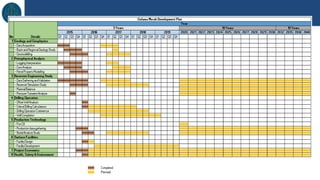

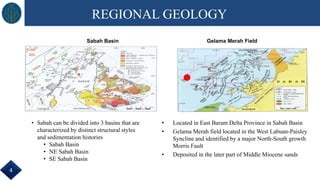

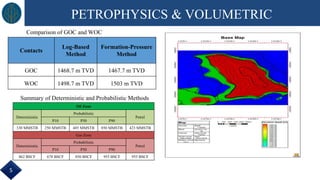

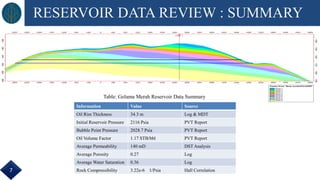

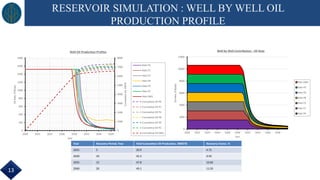

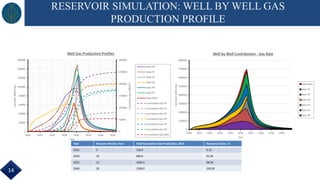

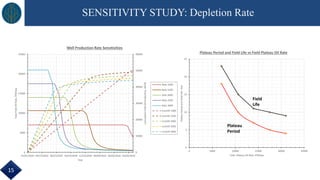

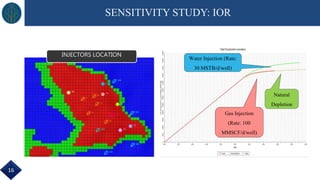

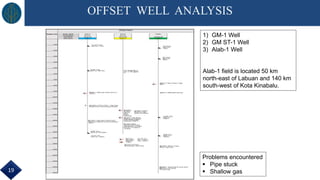

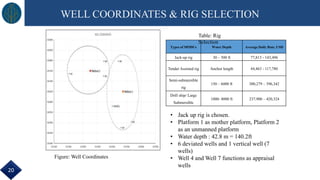

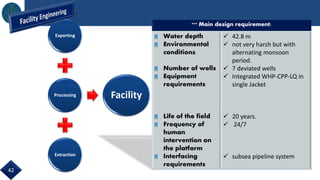

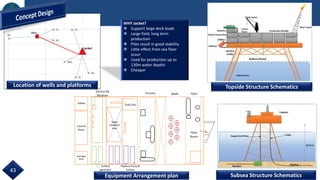

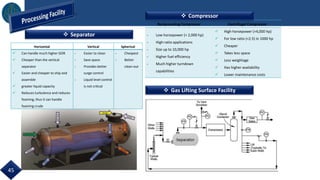

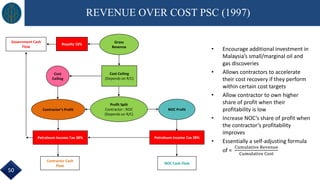

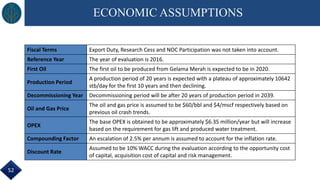

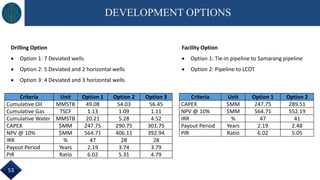

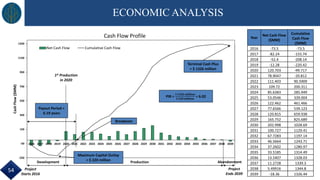

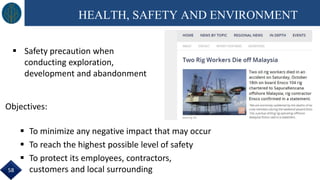

The document outlines a comprehensive study on the Gelama Merah oil field in offshore Sabah, Malaysia, focusing on reservoir engineering, drilling engineering, production technology, and project economics. The main goal is to generate a reliable Field Development Plan (FDP) report for management decision-making amid various challenges such as time constraints and limited data. The report includes detailed analysis on regional geology, petrophysics, reservoir management, and drilling strategies, along with results from reservoir simulations and production forecasts.